At its core, Cold Isostatic Pressing (CIP) is a manufacturing process that uses high-pressure fluid at room temperature to uniformly compress powdered materials. The powder is sealed in a flexible mold and submerged in a liquid, which is then pressurized from all sides to compact the powder into a solid, cohesive shape known as a "green body."

The true value of CIP is not simply creating a solid shape, but creating a component with exceptionally uniform density. This uniformity is the key to producing high-integrity final parts after subsequent firing, even if it means sacrificing initial dimensional precision.

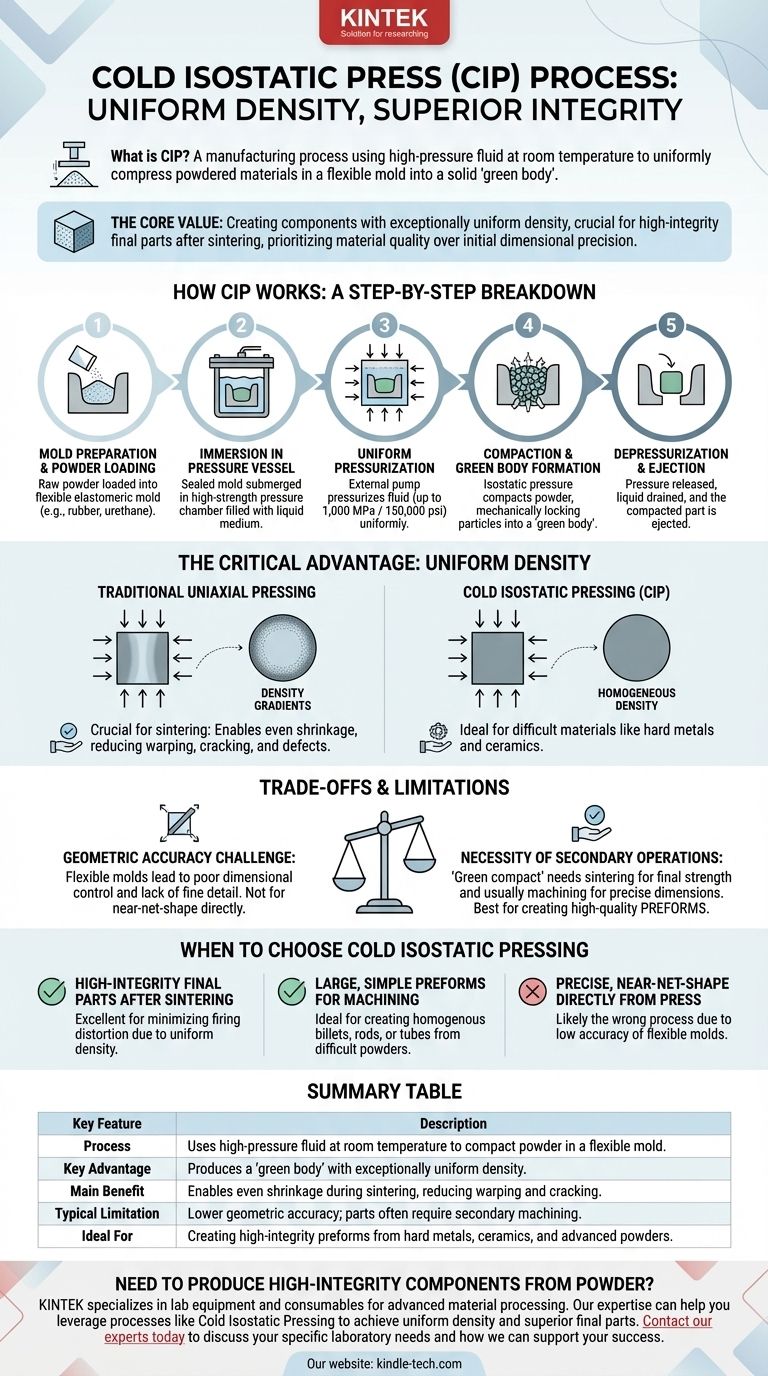

How Cold Isostatic Pressing Works: A Step-by-Step Breakdown

The CIP process is conceptually simple but powerful in its execution. It transforms loose powder into a solid object through the methodical application of immense, uniform pressure.

Step 1: Mold Preparation and Powder Loading

First, the raw material in powder form is loaded into a flexible, elastomeric mold. These molds are typically made of materials like rubber, urethane, or polyvinyl chloride that can deform easily under pressure.

Step 2: Immersion in the Pressure Vessel

The filled and sealed mold is placed inside a high-strength pressure chamber. This vessel is engineered to withstand severe, cyclic loading from extremely high pressures.

Step 3: Uniform Pressurization

The chamber is filled with a liquid medium, usually water with a corrosion inhibitor or a specialized oil. An external pump pressurizes this fluid, sometimes to levels as high as 1,000 MPa (150,000 psi).

Step 4: Compaction and Green Body Formation

The liquid transmits the pressure equally and simultaneously to every surface of the flexible mold. This isostatic pressure collapses the mold, compacting the powder particles inside and mechanically locking them together. The resulting solid part is called a "green compact" or "green body."

Step 5: Depressurization and Ejection

After a brief hold, the pressure is released, and the liquid is drained. The mold returns to its original shape, allowing for the easy removal of the newly formed, compacted part.

The Critical Advantage: Uniform Density

The defining feature of CIP is the quality of the component it produces. Unlike other pressing methods, the use of fluid pressure guarantees a uniquely homogeneous result.

Why Isostatic Pressure Matters

In traditional uniaxial pressing, where pressure is applied from one or two directions, density gradients are common. The areas closest to the press are denser than those in the center. Isostatic pressure eliminates this issue, ensuring every part of the component has a consistent density.

The Benefit for Post-Processing

This uniform density is crucial for secondary operations, especially sintering (firing at high temperatures to fully bond the particles). A uniformly dense green body will shrink predictably and evenly during sintering, dramatically reducing the risk of warping, cracking, or internal defects.

Applications for Difficult Materials

CIP is exceptionally well-suited for powders that are difficult to press using conventional methods. This includes hard metals, ceramics, and other advanced materials that do not compact easily under directional force.

Understanding the Trade-offs and Limitations

While powerful, CIP is not a universal solution. Its unique characteristics create specific trade-offs that are critical to understand.

The Challenge of Geometric Accuracy

The primary disadvantage of CIP is its low geometric accuracy. The same flexible mold that enables uniform pressure also results in poor dimensional control and a lack of fine detail. The final shape will not have tight tolerances directly out of the press.

The Necessity of Secondary Operations

A part made by CIP is almost never a finished product. The "green compact" has the consistency of chalk and requires a subsequent sintering process to achieve its final strength and material properties.

Furthermore, due to the low geometric accuracy, most CIP parts require final machining to meet precise dimensional specifications. It is best thought of as a process for creating high-quality preforms.

When to Choose Cold Isostatic Pressing

Selecting CIP depends entirely on your end-goal for the material and the component's final requirements.

- If your primary focus is producing high-integrity, defect-free final parts after sintering: CIP is an excellent choice because its uniform density minimizes firing-related distortion and cracking.

- If your primary focus is creating large, simple preforms for subsequent machining: CIP is ideal for creating homogenous billets, rods, or tubes from powders that are otherwise difficult to compact.

- If your primary focus is achieving a precise, near-net-shape part directly from the press: CIP is likely the wrong process due to the inherent low accuracy of its flexible molds.

By understanding its role as a preparatory step for creating superior material structures, you can leverage CIP to achieve unparalleled quality in your final product.

Summary Table:

| Key Feature | Description |

|---|---|

| Process | Uses high-pressure fluid at room temperature to compact powder in a flexible mold. |

| Key Advantage | Produces a 'green body' with exceptionally uniform density. |

| Main Benefit | Enables even shrinkage during sintering, reducing warping and cracking. |

| Typical Limitation | Lower geometric accuracy; parts often require secondary machining. |

| Ideal For | Creating high-integrity preforms from hard metals, ceramics, and advanced powders. |

Need to produce high-integrity components from powder?

KINTEK specializes in lab equipment and consumables for advanced material processing. Our expertise can help you leverage processes like Cold Isostatic Pressing to achieve uniform density and superior final parts. Contact our experts today to discuss your specific laboratory needs and how we can support your success.

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What are the different parts of a single punch tablet machine? The Core Components Explained

- What are the different pill presses? Choose the Right Machine for Your Lab or Production Scale

- What is a punch tablet press? Precision Tableting for R&D and Small Batches

- What is the pressed pellet technique? A Guide to Creating Uniform Solid Samples from Powder

- What is the difference between single punch and rotary tablet press? Choose the Right Machine for Your Lab or Production