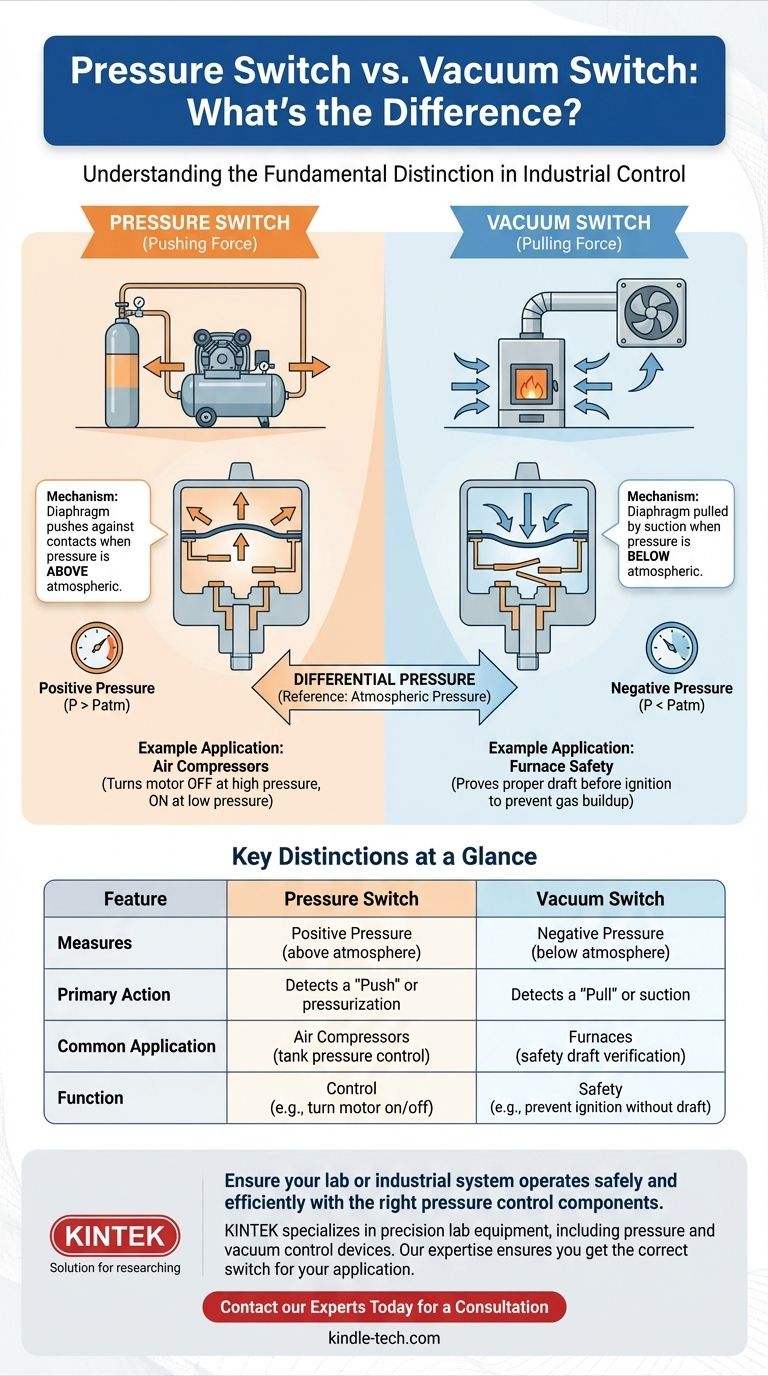

At its core, the difference is simple. A standard pressure switch activates when it detects a pressure higher than the surrounding atmosphere—a pushing force. A vacuum switch is its opposite, activating when it detects a pressure lower than the surrounding atmosphere—a pulling or sucking force.

While both are technically types of pressure switches that open or close an electrical circuit, the key distinction is their trigger: one responds to positive pressure (a push), and the other responds to negative pressure, or vacuum (a pull).

How a Pressure Switch Works

A pressure switch is an electromechanical device that monitors the pressure in a system and automatically triggers an electrical contact when a certain pressure level is reached.

The Core Mechanism: Diaphragm and Contacts

Think of a small, flexible diaphragm inside the switch. As the pressure in the system rises, it pushes against this diaphragm.

Once the pressure exerts enough force to cross a preset threshold, the diaphragm moves and physically closes (or opens) an electrical circuit, much like flipping a light switch.

Common Application: Air Compressors

A classic example is an air compressor. A pressure switch monitors the tank's internal air pressure.

When the pressure reaches the cut-off point (e.g., 120 PSI), the switch activates and turns the motor off. When you use the air and the pressure drops to the cut-in point (e.g., 90 PSI), the switch turns the motor back on to refill the tank.

How a Vacuum Switch Works

A vacuum switch operates on the exact same principle as a pressure switch but is engineered to react to the opposite force: suction, also known as negative pressure.

The Core Mechanism: A Mirror Image

Inside a vacuum switch, the diaphragm is set up to move when air is pulled away from it, creating a pressure differential lower than the ambient air.

When the suction is strong enough, it pulls the diaphragm, which in turn closes the electrical circuit. This confirms that a vacuum or a proper draft is present.

Common Application: Furnace Safety

Your reference provides the perfect use case: a modern gas furnace. The furnace's draft inducer motor is a fan designed to pull exhaust gases out of the heat exchanger and vent them safely outside.

The vacuum switch is a safety device that proves this fan is running and creating sufficient suction before the furnace is allowed to ignite its main burners. If the vent is blocked or the fan fails, the switch won't close, and the furnace will not light, preventing a dangerous buildup of carbon monoxide.

Understanding the Trade-offs and Key Distinction

While related, these two components serve fundamentally different purposes and are not interchangeable. Confusing them can lead to system failure or significant safety risks.

It's All About the Reference Point

Both switches measure differential pressure, which is the difference between the pressure in your system and the surrounding atmospheric pressure.

Positive Pressure: A Pushing Force

A standard pressure switch is calibrated to actuate when the system pressure is measurably above atmospheric pressure. It is designed to confirm a pressurization event.

Negative Pressure: A Pulling Force

A vacuum switch is calibrated to actuate when the system pressure is measurably below atmospheric pressure. It is designed to confirm a suction or venting event.

Making the Right Choice for Your Goal

Selecting the correct switch is not a matter of preference; it is dictated entirely by the physics of the system you are controlling or monitoring.

- If your primary focus is to confirm a system is pressurized: You need a standard pressure switch to detect when a target positive pressure has been reached.

- If your primary focus is to confirm a system is venting or creating suction: You need a vacuum switch to verify that a negative pressure draft has been established.

- If you are troubleshooting a system like a furnace: Recognizing that it uses a vacuum switch to prove proper venting is the first step in diagnosing startup failures.

Ultimately, understanding whether your system needs to push or pull is the key to selecting and diagnosing these critical components correctly.

Summary Table:

| Feature | Pressure Switch | Vacuum Switch |

|---|---|---|

| Measures | Positive Pressure (above atmosphere) | Negative Pressure (below atmosphere) |

| Primary Action | Detects a 'Push' or pressurization | Detects a 'Pull' or suction |

| Common Application | Air Compressors (tank pressure control) | Furnaces (safety draft verification) |

| Function | Control (e.g., turn motor on/off) | Safety (e.g., prevent ignition without draft) |

Ensure your lab or industrial system operates safely and efficiently with the right pressure control components.

KINTEK specializes in precision lab equipment and consumables, including pressure and vacuum control devices. Whether you're building a new system or troubleshooting an existing one, our expertise ensures you get the correct switch for your specific application—guaranteeing both performance and safety.

Don't risk system failure. Contact our experts today for a consultation and find the perfect solution for your pressure or vacuum needs!

Visual Guide

Related Products

- 304 316 Stainless Steel Vacuum Ball Valve Stop Valve for High Vacuum Systems

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What are the technical advantages of using high-speed mechanical stirrers in corn oil methanolysis? Boost Efficiency

- What function do magnetic stirrers perform in SLM silver separation? Optimize Mass Transfer for Silver Recovery

- Why are zirconia milling jars and balls required for Li2S composites? Ensure Purity in Solid Electrolyte Synthesis

- What does a vacuum switch do? Automate Control with Simple On/Off Signals

- What technical considerations are involved in selecting quartz reaction tubes for biomass pyrolysis? Optimize Efficiency

- What are the advantages of using zirconia grinding balls for Zr2Al-GNS? Ensure High Purity and Peak Electrical Performance

- What is the thickness of quartz tubing? Choose the Right Wall Thickness for Your Application

- Why are high-temperature packing seals used instead of standard silicone O-rings? Ensure Safety and Integrity