In short, bio-oil is a liquid fuel and biochar is a solid soil amendment. Both are valuable products derived from the same process—pyrolysis—which involves heating organic material like wood or crop waste in the absence of oxygen. The key difference lies in their physical state, which dictates their distinct properties and applications.

The core distinction is simple: bio-oil is a liquid energy carrier, while biochar is a solid carbon-rich material. They represent two different paths for valorizing biomass, one focused on fuel and chemicals, the other on soil health and carbon sequestration.

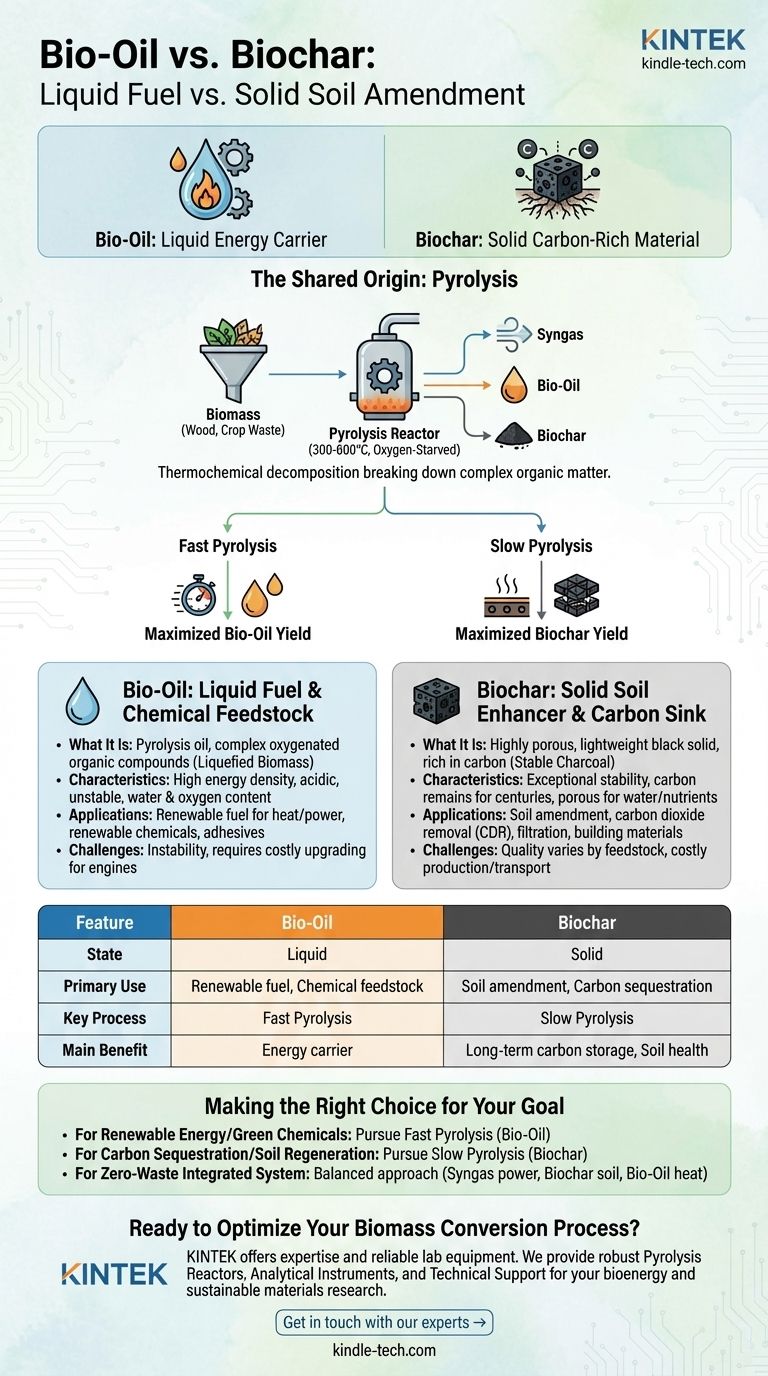

The Shared Origin: Understanding Pyrolysis

To grasp the difference between bio-oil and biochar, you must first understand the process that creates them. Both are children of pyrolysis, a thermochemical reaction that breaks down complex organic matter.

What is Pyrolysis?

Pyrolysis is the thermal decomposition of biomass at high temperatures (typically 300-600°C) in an oxygen-starved environment.

Instead of burning the material, which would produce mostly ash and heat, this process breaks it down into its constituent components, resulting in three primary outputs: a liquid (bio-oil), a solid (biochar), and a gas (syngas).

How Production Conditions Create Different Products

The final yields of bio-oil versus biochar are not accidental. They are controlled by the specific conditions of the pyrolysis process, primarily the heating rate and temperature.

Fast pyrolysis, which involves heating the biomass very quickly, maximizes the production of bio-oil. In contrast, slow pyrolysis, which uses a slower heating rate over a longer period, is designed to maximize the yield of biochar.

Bio-Oil: The Liquid Fuel and Chemical Feedstock

Bio-oil is often seen as a potential renewable substitute for some petroleum products. It represents the condensable liquid fraction produced during pyrolysis.

What It Is

Also known as pyrolysis oil, bio-oil is a dark, viscous, and complex mixture of oxygenated organic compounds. It is essentially a liquefied form of the original biomass.

Key Characteristics

Bio-oil has a high energy density compared to the raw biomass it came from, but it is also highly acidic, unstable, and contains a significant amount of water and oxygen. These characteristics mean it cannot be used as a "drop-in" fuel in conventional engines without significant upgrading or refining.

Common Applications

The primary interest in bio-oil lies in its potential as a renewable fuel for heat and power generation in industrial boilers. It is also explored as a source for producing renewable platform chemicals, adhesives, and even components for asphalt.

Biochar: The Solid Soil Enhancer and Carbon Sink

While bio-oil is valued for the energy it contains, biochar is valued for the stable carbon it embodies. It is the solid, charcoal-like material left behind after pyrolysis.

What It Is

Biochar is a highly porous, lightweight black solid that is rich in carbon. Unlike charcoal made for fuel, biochar is specifically produced for agricultural and environmental purposes.

Key Characteristics

Its most important feature is its stability. The carbon in biochar can remain locked in the soil for hundreds or even thousands of years, making it an exceptional tool for carbon sequestration. Its porous structure also allows it to retain water and nutrients, improving soil health.

Common Applications

Biochar's primary use is as a soil amendment to improve fertility, water retention, and microbial activity in agriculture. It is also a globally recognized method for carbon dioxide removal (CDR) and can be used in filtration systems and as an additive in building materials.

Understanding the Trade-offs

Neither bio-oil nor biochar is a perfect solution. Their production and use involve critical trade-offs that are important to understand.

Bio-Oil's Challenge: Instability and Refining

The biggest hurdle for bio-oil is its poor quality compared to conventional crude oil. It is corrosive and chemically unstable, meaning it thickens and degrades over time. It requires costly and energy-intensive upgrading to be converted into transportation fuels like gasoline or diesel.

Biochar's Challenge: Consistency and Cost

The quality of biochar can vary dramatically depending on the feedstock (e.g., wood vs. manure) and production conditions. This lack of standardization is a challenge for large-scale agricultural applications. Furthermore, production and transportation can be costly, impacting its economic viability.

The Production Dilemma: Optimizing for One Reduces the Other

You cannot simultaneously maximize the yield of both products from a single process. A system designed for high bio-oil output (fast pyrolysis) will inherently produce less biochar, and a system optimized for high biochar output (slow pyrolysis) will yield very little bio-oil.

Making the Right Choice for Your Goal

The decision to focus on bio-oil or biochar production depends entirely on the desired outcome.

- If your primary focus is renewable energy or green chemicals: You should pursue fast pyrolysis to maximize the production of bio-oil.

- If your primary focus is carbon sequestration and soil regeneration: You should pursue slow pyrolysis to maximize the yield and quality of biochar.

- If your primary focus is a zero-waste, integrated system: You should consider a balanced approach where the syngas powers the process, the biochar improves local soils, and the bio-oil is used for on-site heating or power.

Understanding that bio-oil and biochar are two different tools derived from the same process allows you to select the right output for your specific environmental or economic goal.

Summary Table:

| Feature | Bio-Oil | Biochar |

|---|---|---|

| State | Liquid | Solid |

| Primary Use | Renewable fuel, chemical feedstock | Soil amendment, carbon sequestration |

| Key Process | Fast Pyrolysis | Slow Pyrolysis |

| Main Benefit | Energy carrier | Long-term carbon storage, soil health |

Ready to Optimize Your Biomass Conversion Process?

Whether your project requires equipment for fast pyrolysis to produce bio-oil or slow pyrolysis systems for high-quality biochar, KINTEK has the expertise and reliable lab equipment to support your research and development.

We help our customers in the bioenergy and sustainable materials sectors by providing:

- Robust Pyrolysis Reactors for precise temperature control and optimal product yield.

- Analytical Instruments to characterize your bio-oil and biochar products.

- Consumables and Technical Support to ensure your experiments run smoothly and deliver accurate, reproducible results.

Contact us today to discuss how our solutions can help you achieve your specific goals in renewable energy, carbon sequestration, or soil science.

Get in touch with our experts →

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- High Performance Laboratory Freeze Dryer for Research and Development

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products