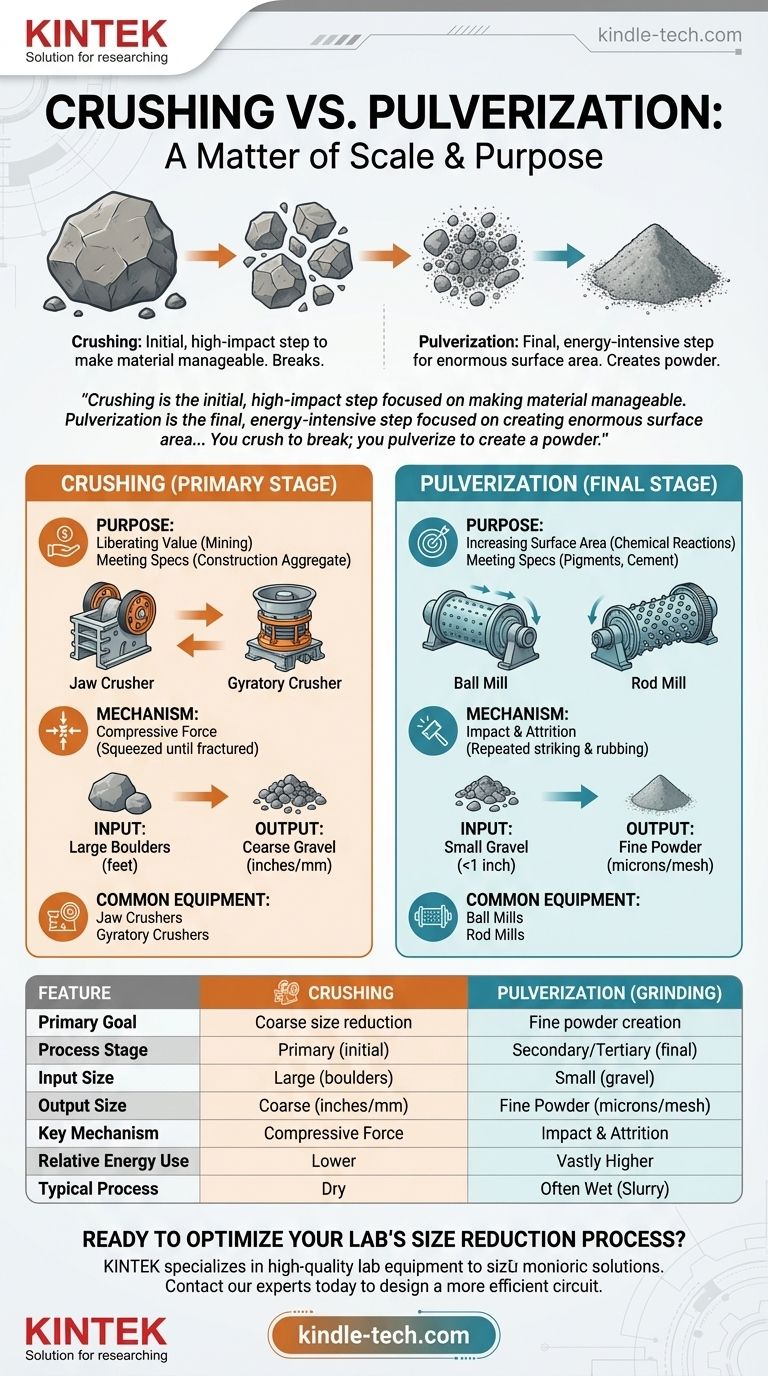

At its core, the difference between crushing and pulverization is a matter of scale and final purpose. Both are methods of comminution (size reduction), but they operate at opposite ends of the process. Crushing is the primary, brute-force stage that breaks large, coarse materials into smaller, gravel-like pieces. Pulverization, also known as grinding, is the secondary or tertiary stage that takes those smaller pieces and reduces them into a fine powder.

Crushing is the initial, high-impact step focused on making material manageable. Pulverization is the final, energy-intensive step focused on creating enormous surface area and achieving a specific fine-particle consistency. You crush to break; you pulverize to create a powder.

The Purpose of Size Reduction

All size reduction, or comminution, serves a specific industrial or scientific purpose. Understanding the end goal is the key to selecting the right process.

The Goal: Liberating Value

In mining, valuable minerals are often locked within worthless rock (gangue). The material must be broken down until the mineral particles are physically separate, or "liberated," so they can be extracted through chemical processes.

The Goal: Increasing Surface Area

Many chemical reactions, from cement hydration to pharmaceutical absorption, happen on the surface of a particle. By pulverizing a material into a fine powder, you dramatically increase its total surface area, which in turn accelerates reaction rates and improves product performance.

The Goal: Meeting Product Specifications

Many final products are defined by their particle size. Concrete requires specific sizes of crushed stone (aggregate), while paints and cosmetics require finely pulverized pigments for a smooth, uniform consistency.

Crushing: The Primary Stage of Force

Crushing is always the first step in any significant size reduction circuit. It deals with the largest and toughest materials directly from a quarry or mine.

The Mechanism: Compressive Force

Crushing equipment works primarily by compression. Material is caught between two hard surfaces—one or both of which are moving—and is squeezed until it fractures. The force is immense, designed to overcome the material's inherent strength.

Input and Output: From Boulders to Gravel

Crushers take large feed, from boulders several feet in diameter down to large rocks. The output is significantly smaller but still coarse, typically measured in inches or millimeters (e.g., from 6 inches down to 1/2 inch).

Common Equipment: Jaw and Gyratory Crushers

Jaw crushers use a fixed and a moving plate to "chew" rock. Gyratory crushers use a conical head that rotates eccentrically inside a fixed bowl, creating a compression zone around the entire circumference. Both are heavy-duty machines built for high throughput and reliability.

Pulverization: The Final Stage of Refinement

Pulverization, or grinding, is a finishing process. It takes the relatively small output from a crusher and refines it into a powder.

The Mechanism: Impact and Attrition

Pulverizers work less by pure compression and more through a combination of impact and attrition. Inside a grinding mill, media like steel balls or rods are tumbled with the material. They repeatedly strike the particles (impact) and rub against them (attrition), chipping away at them until they are microscopic.

Input and Output: From Gravel to Powder

The feed for a pulverizer is already small, typically less than an inch. The output is a very fine powder, often measured in microns (a millionth of a meter) or mesh size. The goal is to produce a consistent, dust-like material.

Common Equipment: Ball and Rod Mills

Ball mills are large rotating cylinders filled with steel balls that tumble and cascade, grinding the material into a fine powder. Rod mills operate similarly but use long steel rods, which are better for preventing over-grinding of softer materials.

Understanding the Trade-offs

Choosing between, or combining, these processes involves significant engineering and economic considerations. The differences in energy, cost, and operation are substantial.

Energy Consumption: A Law of Diminishing Returns

It takes exponentially more energy to make a particle smaller as it decreases in size. Creating a tiny amount of new surface area on a fine powder requires far more energy than creating a large amount of surface area by breaking a big rock. Consequently, pulverization is vastly more energy-intensive than crushing.

Equipment and Maintenance Costs

Crushers are massive, heavy-duty machines, but their mechanics are relatively straightforward. Grinding mills are also large, but they often operate in more complex circuits with classifiers, pumps, and control systems to manage the final particle size. The internal wear parts (liners and grinding media) of a mill are also a significant and recurring operational cost.

Process Environment: Dry vs. Wet

Crushing is almost always a dry process. Pulverization, especially in high-volume mineral processing, is very often a wet process. Water is added to create a slurry, which helps control dust, transport material, and prepare it for subsequent chemical separation steps.

Making the Right Choice for Your Goal

The decision is not about which process is "better," but which is required to meet your objective. In many large-scale operations, both are used in sequence.

- If your primary focus is producing aggregate for construction or breaking down large ore for transport: You need a crushing process to achieve the required coarse particle size.

- If your primary focus is creating a fine powder for cement, pigments, or to maximize surface area for chemical reactions: You need a pulverization (grinding) process.

- If your primary focus is liberating fine-grained minerals from mined ore: You need a multi-stage circuit that uses crushing first, followed by one or more stages of pulverization.

By understanding this fundamental distinction, you can design an efficient, cost-effective size reduction circuit tailored precisely to your material and your final product specification.

Summary Table:

| Feature | Crushing | Pulverization (Grinding) |

|---|---|---|

| Primary Goal | Coarse size reduction, making material manageable | Fine powder creation, increasing surface area |

| Process Stage | Primary (initial) | Secondary/Tertiary (final) |

| Input Size | Large (e.g., boulders, feet/inches) | Small (e.g., gravel, <1 inch) |

| Output Size | Coarse (inches/millimeters) | Fine Powder (microns/mesh) |

| Key Mechanism | Compressive Force | Impact and Attrition |

| Common Equipment | Jaw Crushers, Gyratory Crushers | Ball Mills, Rod Mills |

| Relative Energy Use | Lower | Vastly Higher |

| Typical Process | Dry | Often Wet (Slurry) |

Ready to optimize your lab's size reduction process?

Whether you need robust equipment for primary crushing or precision mills for fine pulverization, KINTEK has the solution. We specialize in high-quality lab equipment and consumables, helping you achieve the exact particle size your research or production requires.

Contact our experts today to discuss your specific material and application. Let us help you design a more efficient and cost-effective comminution circuit.

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What is a grinder used for in a laboratory? Achieve Accurate & Homogeneous Sample Prep

- What is the machine used in a feed mill? Discover the Complete System for Quality Feed Production

- Which mill is preferred for weight grinding? The Ultimate Guide to Processing Heavy, Viscous Materials

- What is the role of grinding media in milling efficiency? Match Media Size to Your Material for Optimal Results

- What is the purpose of the grinding process for Titanium Dioxide? Maximize Surface Area and Photocatalytic Efficiency

- What does a colloid mill do? Achieve Superior Emulsions and Fine Dispersions

- What is the primary purpose of using a forced-air drying oven and grinding/sieving equipment? Optimize Manure Processing

- What are the advantages of large-diameter stainless steel grinding balls? Optimize Hydrogen Material Preparation