The fundamental difference between Class S and Class N autoclaves lies in how they remove air from the sterilization chamber. Class N autoclaves use passive steam displacement (gravity) for simple, unwrapped solid instruments, while Class S autoclaves use an active vacuum pump to remove air, allowing them to sterilize a wider range of items, including some wrapped and hollow instruments.

The choice between an S-type and N-type autoclave is not about which is universally "better," but about matching the machine's air removal capability to the complexity of the items you must sterilize. This decision directly impacts sterilization reliability, cost, and compliance.

The Core Difference: Air Removal Method

The effectiveness of steam sterilization hinges on a single principle: steam must make direct contact with every surface of an object. Trapped air creates cold spots where microorganisms can survive. The autoclave "class" simply defines the method used to remove this air.

Class N Autoclaves: The Gravity Method

Class N autoclaves, where 'N' stands for Naked solid products, represent the simplest form of steam sterilization.

They operate on the principle of gravity displacement. As hot steam is fed into the chamber, it displaces the cooler, denser air, which is forced out through a drain or vent at the bottom. These are sometimes called "pressure cooker type" or "gravity flow" autoclaves.

Why Gravity Has Limitations

This passive method is effective for simple, solid objects like scalpels, forceps, or laboratory glassware.

However, air can easily become trapped inside hollow tubes, within the fibers of porous materials like textiles, or inside wrapped instrument packs. This trapped air prevents steam from penetrating, leading to sterilization failure.

Class S Autoclaves: The Pre-Vacuum Advantage

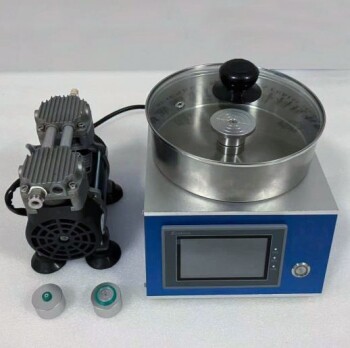

Class S autoclaves, where 'S' stands for Specified products, solve this problem by actively removing air before sterilization begins.

They incorporate a vacuum pump to create a single negative pressure pulse, pulling air out of the chamber and from within hollow or wrapped items. Only after this pre-vacuum stage is steam introduced, ensuring it can penetrate deeper and reach all surfaces.

What "Class S" Really Means

The "Specified" designation indicates that a Class S autoclave is designed for sterilizing specific items defined by its manufacturer.

Unlike the highly regulated Class B autoclaves, the capabilities of a Class S machine can vary. It is a defined middle ground, more capable than a Class N but less versatile than a Class B.

Understanding the Trade-offs

Choosing the correct autoclave requires balancing sterilization needs against operational costs and complexity.

Application: What Can You Sterilize?

- Class N: Exclusively for unwrapped, solid instruments and labware (e.g., petri dishes, solid metal tools, test tubes). Not suitable for textiles, porous items, hollow instruments, or wrapped items.

- Class S: Suitable for everything a Class N can handle, plus single-wrapped items and certain types of hollow instruments. Always verify the manufacturer’s specifications to ensure it can handle your specific load type.

Cost and Complexity

Class N autoclaves are mechanically simpler. They lack a vacuum pump, making them less expensive to purchase and often easier and cheaper to maintain.

Class S autoclaves are more complex and therefore have a higher initial cost. The vacuum pump is an additional component that may require service over the machine's lifetime.

Cycle Time and Efficiency

While cycle times vary, Class S autoclaves often feature more efficient, vacuum-assisted drying cycles. This can result in faster overall processing and instruments that are ready for use more quickly.

A Note on Class B Autoclaves

To fully understand the Class S position, it helps to know about Class B.

The Highest Standard

Class B autoclaves (think 'B' for Big loads) are the most versatile. They use a powerful, fractionated pre-vacuum (multiple vacuum pulses) to remove air from the most challenging loads.

This makes them suitable for sterilizing porous materials (surgical gowns, drapes), heavily wrapped surgical kits, and complex hollow instruments used in surgery and dentistry.

Making the Right Choice for Your Goal

Your choice must be guided by the most difficult items you need to sterilize to ensure safety and regulatory compliance.

- If your primary focus is basic labware: A Class N autoclave is the most cost-effective and reliable choice for sterilizing unwrapped, solid items like glassware and simple tools.

- If your primary focus is clinical or dental instruments: A Class S autoclave is the minimum requirement for sterilizing single-wrapped items or instruments with hollow sections.

- If your primary focus is complex surgical kits or porous loads: Neither N nor S is sufficient. A Class B autoclave is the only appropriate choice to guarantee sterilization of textiles and multi-wrapped kits.

Understanding the distinction between gravity and vacuum-based air removal empowers you to select the precise autoclave class that guarantees safety and compliance for your specific needs.

Summary Table:

| Feature | Class N Autoclave | Class S Autoclave |

|---|---|---|

| Air Removal Method | Gravity Displacement | Pre-Vacuum Pump |

| Primary Use | Unwrapped, Solid Items | Unwrapped & Some Wrapped/Hollow Items |

| Cost & Complexity | Lower Cost, Simpler | Higher Cost, More Complex |

| Ideal For | Basic Labware (Glassware, Tools) | Clinical/Dental Instruments |

Unsure which autoclave class is right for your laboratory's specific instruments?

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select the perfect sterilizer—whether it's a cost-effective Class N for basic glassware or a versatile Class S for wrapped and hollow instruments—to ensure compliance, safety, and efficiency.

Contact our sterilization specialists today for a personalized consultation and ensure your lab's critical work is protected.