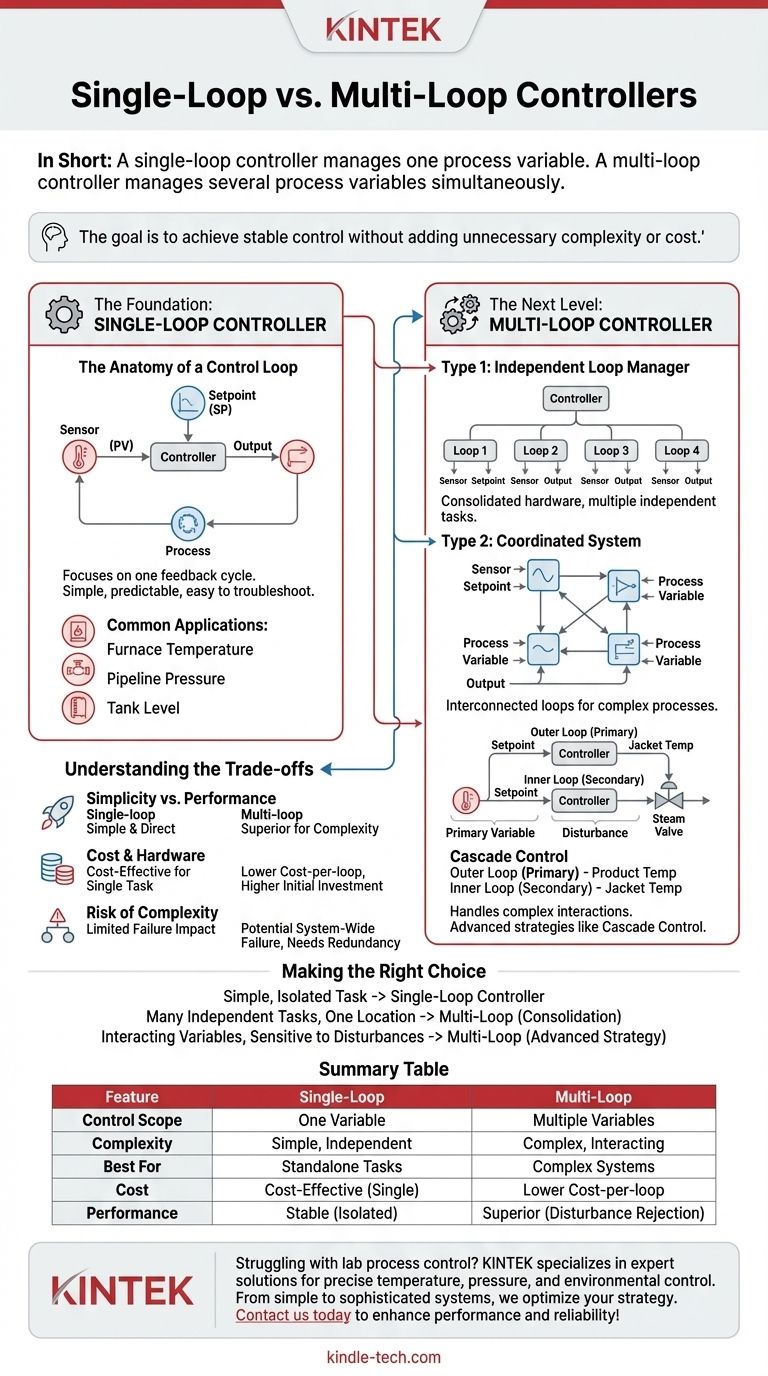

In short, a single-loop controller manages one specific process variable, like the temperature of a single oven. In contrast, a multi-loop controller is designed to manage several process variables simultaneously, often by coordinating their interactions to control a more complex system.

The decision between a single-loop and a multi-loop controller is not about which is superior, but which one correctly matches the complexity of your process. The goal is to achieve stable control without adding unnecessary complexity or cost.

The Foundation: Understanding the Single Loop

A single-loop controller is the fundamental building block of industrial automation. It is designed to perform one job and do it reliably.

The Anatomy of a Control Loop

Every basic control loop consists of four key elements:

- A Sensor: Measures the current state, known as the Process Variable (PV).

- A Setpoint (SP): The desired target value for that variable.

- A Controller: Compares the PV to the SP and calculates a corrective action.

- An Output: The physical device (like a valve or heater) that the controller adjusts.

Think of the cruise control in your car. The speed sensor is the PV, your desired speed is the SP, the controller is the computer, and the output is the engine's throttle.

How a Single-Loop Controller Works

A single-loop controller focuses on this one feedback cycle exclusively. It measures one variable, compares it to one setpoint, and manipulates one output.

This direct, one-to-one relationship makes it straightforward to implement, tune, and troubleshoot. Its behavior is predictable because it is not influenced by other control processes.

Common Applications

Single-loop controllers are ideal for simple, standalone tasks where one variable needs to be maintained. Common examples include:

- Maintaining the temperature in a furnace.

- Regulating the pressure in a pipeline.

- Keeping the liquid level constant in a storage tank.

The Next Level: The Multi-Loop Controller

Multi-loop controllers handle situations where single-loop control is insufficient. They come in two primary forms: as a consolidated manager of independent loops or as a sophisticated coordinator of interacting loops.

Type 1: The Independent Loop Manager

In its simplest form, a multi-loop controller is a single piece of hardware that runs multiple, independent single loops. Instead of having four separate controllers for four different ovens, you have one device managing all four.

This is primarily a matter of hardware consolidation, saving panel space, reducing wiring, and often lowering the cost per loop. The loops themselves do not interact.

Type 2: The Coordinated System

The true power of multi-loop control is revealed when the loops are interconnected. This is used for complex processes where variables influence each other. Advanced strategies become possible.

Example: Cascade Control

A classic multi-loop strategy is cascade control. Imagine trying to control the temperature of a product inside a large, jacketed tank by manipulating the steam valve that heats the jacket.

A single loop would measure the slow-changing product temperature and adjust the steam. If steam pressure fluctuates (a disturbance), the product temperature will deviate long before the controller can correct it.

A cascade system uses two loops:

- Outer Loop (Primary): Measures the product temperature (the ultimate goal) and calculates a setpoint for the jacket temperature.

- Inner Loop (Secondary): Measures the jacket temperature and rapidly adjusts the steam valve to meet the setpoint provided by the outer loop.

This design isolates the primary variable (product temperature) from disturbances in the energy source (steam pressure), resulting in much tighter and more stable control.

Understanding the Trade-offs

Choosing the right controller requires a clear-eyed view of the trade-offs between simplicity and performance.

Simplicity vs. Performance

A single-loop controller is simple. Tuning is confined to that one loop, and troubleshooting is direct.

A multi-loop controller, especially one with interacting loops like a cascade system, offers far superior performance for complex processes. However, it requires more expertise to design, implement, and tune, as adjusting one loop can affect the others.

Cost and Hardware

For a single control task, a dedicated single-loop controller is almost always the most cost-effective solution.

For systems with many control points, a multi-loop controller can offer a lower cost-per-loop and reduce installation expenses. However, the initial investment in the hardware and engineering time is higher.

The Risk of Complexity

A key consideration is the "blast radius" of a failure. If a single-loop controller fails, it only affects one process. If a multi-loop controller managing ten processes fails, it can bring the entire system down. This requires careful consideration of redundancy and failure modes.

Making the Right Choice for Your Process

Your selection should be driven entirely by the demands of the system you need to control.

- If your primary focus is a simple, isolated task: A single-loop controller offers the best combination of reliability, simplicity, and low cost.

- If you need to manage many independent tasks in one location: A multi-loop controller used for consolidation can save space and simplify system architecture.

- If your process has interacting variables or is sensitive to disturbances: You require an advanced multi-loop strategy like cascade, ratio, or feedforward control to achieve the necessary stability and performance.

Ultimately, the right controller is the one that provides the necessary level of control without introducing unnecessary complexity to your system.

Summary Table:

| Feature | Single-Loop Controller | Multi-Loop Controller |

|---|---|---|

| Control Scope | One process variable | Multiple process variables |

| Complexity | Simple, independent | Can be complex, with interacting loops |

| Best For | Standalone tasks (e.g., furnace temperature) | Complex systems, multi-variable coordination |

| Cost & Hardware | Cost-effective for single tasks | Lower cost-per-loop for multiple tasks |

| Performance | Stable for isolated processes | Superior for disturbance rejection (e.g., cascade control) |

Struggling to achieve stable control in your lab processes? KINTEK specializes in lab equipment and consumables, offering expert solutions for precise temperature, pressure, and environmental control. Whether you need a simple single-loop controller for a standalone furnace or a sophisticated multi-loop system for complex processes, our team can help you design, implement, and optimize the right control strategy.

Contact us today to discuss your specific laboratory control needs and enhance your system's performance and reliability!

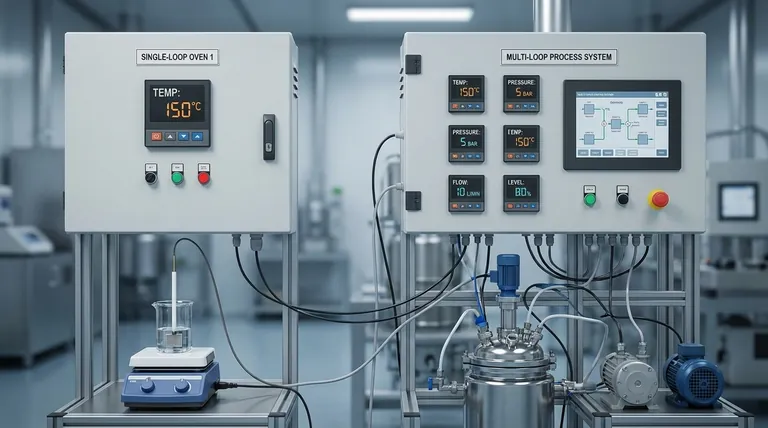

Visual Guide

Related Products

- Platinum Auxiliary Electrode for Laboratory Use

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- What is the function of a magnetic stirrer in SiOC film preparation? Ensure Precision in Precursor Mixing

- What environmental conditions must a ball mill jar meet? Prevent Fe3Al Oxidation with Advanced Sealing

- What is the function of a magnetic stirrer in SiO2FexOy synthesis? Achieve Molecular Homogeneity in Sol-Gel Processes

- How does a quartz ampoule contribute to 7N grade metal production? Achieve 99.99999% Purity with Vacuum Gasification

- What can I use a vacuum pump for? Powering Industrial Processes from Packaging to Automation

- What role does a precision magnetic hotplate stirrer play in the extraction of bioactive compounds? Optimize Your Lab.

- What is the difference between glass tube and quartz tube? A Guide to Thermal & Optical Performance

- How should a polishing cloth be applied to a glass base? Achieve a Perfectly Flat Polishing Surface