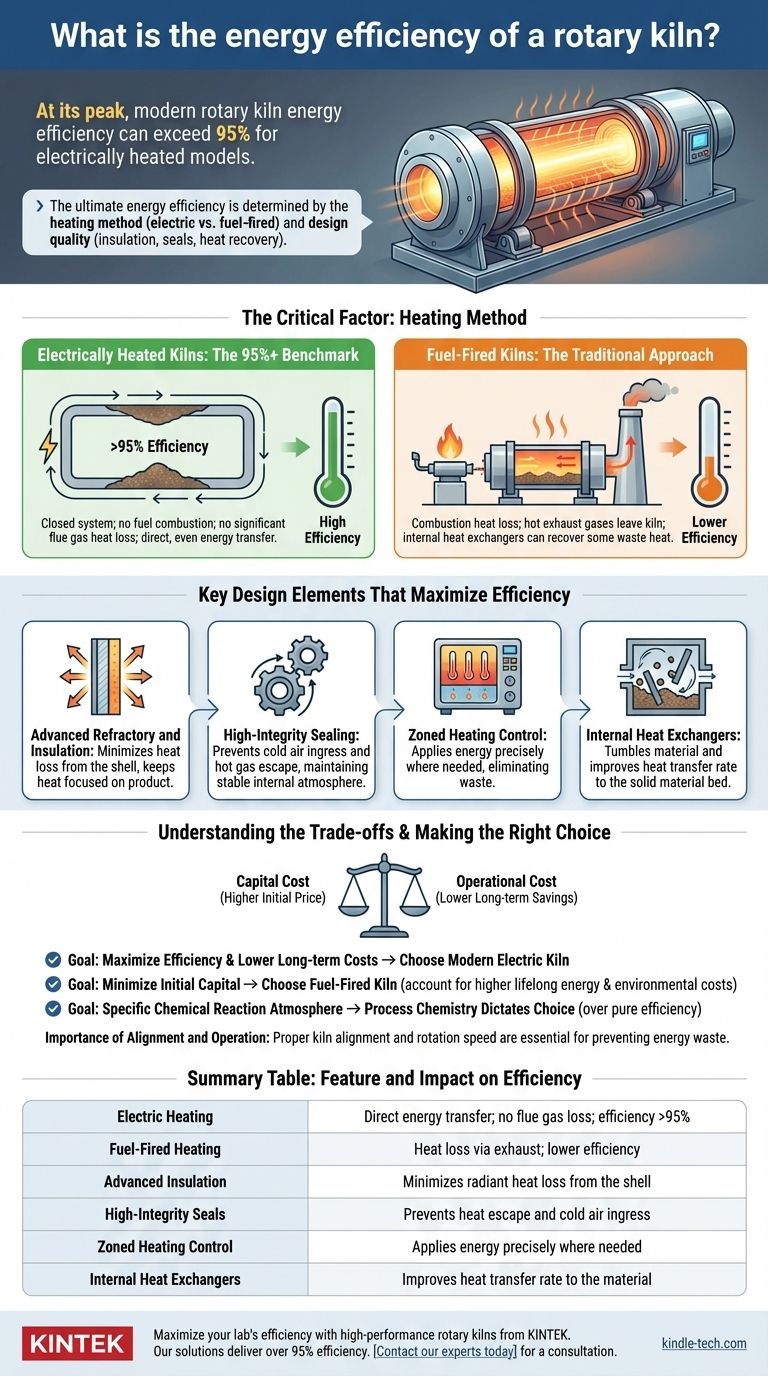

At its peak, the energy efficiency of a modern rotary kiln can be exceptionally high. For electrically heated models, which represent the upper limit of performance, thermal efficiency can exceed 95%. This is achieved by minimizing heat loss and applying energy directly to the material being processed.

The ultimate energy efficiency of a rotary kiln is not a fixed value; it is fundamentally determined by the heating method—electric versus fuel-fired—and the quality of its design, particularly its insulation, seals, and heat recovery systems.

The Critical Factor: Heating Method

The single largest determinant of a rotary kiln's potential efficiency is how it generates and transfers heat. The two primary approaches have vastly different performance profiles.

Electrically Heated Kilns: The 95%+ Benchmark

Modern electric kilns achieve this top-tier efficiency because they are designed as a closed system. With no fuel combustion, there is no need for a massive flow of gas to carry heat, and therefore no significant heat loss through an exhaust stack.

Energy is transferred directly and evenly to the material, often through a 360° heater placement around the shell. This ensures the vast majority of electrical energy consumed is converted directly into useful process heat.

Fuel-Fired Kilns: The Traditional Approach

Conventional direct-fired kilns, which burn natural gas, oil, or other fuels, are inherently less efficient. A significant portion of the heat generated is lost as hot exhaust gases leave the kiln.

While internal heat exchangers can recover some of this waste heat to pre-heat incoming material, the fundamental energy losses associated with flue gas make it difficult to approach the efficiency levels of a closed-system electric kiln.

Key Design Elements That Maximize Efficiency

Beyond the heating source, several engineering features are critical for retaining and effectively using thermal energy.

Advanced Refractory and Insulation

The kiln's refractory lining is its primary defense against heat loss. High-quality, multi-layer insulation within the steel shell minimizes the amount of energy that radiates away from the kiln, keeping the heat focused on the product.

High-Integrity Sealing

Effective seals at the feed and discharge ends of the kiln are crucial. These seals prevent cold ambient air from being drawn into the system and hot internal gases from escaping. This maintains a stable internal atmosphere and prevents the heating system from constantly fighting against temperature drops.

Zoned Heating Control

Advanced kilns feature multiple independent heating zones along their length. This allows operators to create a precise heat pattern that matches the exact requirements of the process (e.g., drying, calcining, reacting). Energy is applied only where it is most needed, eliminating waste.

Internal Heat Exchangers

Components designed as internal heat exchangers, such as lifters or baffles, serve a dual purpose. They tumble the material for uniform processing while also helping to transfer heat from the hot shell or internal atmosphere directly into the solid material bed, improving the rate and efficiency of heat transfer.

Understanding the Trade-offs

Pursuing maximum efficiency involves balancing costs and operational constraints.

Capital Cost vs. Operational Cost

A highly efficient electric rotary kiln with advanced alloys, zoned controls, and superior insulation will have a significantly higher initial purchase price. This capital investment must be weighed against the long-term savings from lower energy consumption.

Process Needs vs. Thermal Efficiency

Sometimes the specific chemistry of a process dictates the kiln type. For example, if the byproducts of direct fuel combustion are required for the chemical reaction, a direct-fired kiln must be used, even if it is less thermally efficient than an indirect electric model.

The Importance of Alignment and Operation

Even the most advanced kiln will operate inefficiently if not installed and maintained correctly. Proper kiln alignment, inclination, and rotation speed are essential for ensuring material moves through the heat zones as designed, maximizing heat transfer and preventing energy waste.

Making the Right Choice for Your Process

Your final decision should be based on a clear understanding of your primary goal.

- If your primary focus is maximizing energy efficiency and lowering long-term operational costs: Choose a modern, electrically heated kiln with independent heating zones and high-integrity seals.

- If your primary focus is minimizing initial capital expenditure: A simpler, fuel-fired kiln may be an option, but you must account for higher lifelong energy costs and environmental impact.

- If your primary focus is a specific chemical reaction requiring a unique atmosphere: Your choice between direct-fired and indirect heating will be dictated by process chemistry, which may take precedence over pure thermal efficiency.

Ultimately, selecting the right rotary kiln requires a holistic view that balances initial investment with the total cost of ownership and specific process demands.

Summary Table:

| Feature | Impact on Efficiency |

|---|---|

| Electric Heating | Direct energy transfer; no flue gas loss; efficiency >95% |

| Fuel-Fired Heating | Heat loss via exhaust; lower efficiency |

| Advanced Insulation | Minimizes radiant heat loss from the shell |

| High-Integrity Seals | Prevents heat escape and cold air ingress |

| Zoned Heating Control | Applies energy precisely where needed |

| Internal Heat Exchangers | Improves heat transfer rate to the material |

Maximize your lab's efficiency and reduce operational costs with a high-performance rotary kiln from KINTEK.

Our rotary kilns are engineered for superior thermal performance, featuring advanced electric heating systems, multi-zone control, and robust insulation to deliver over 95% efficiency. Whether your priority is minimizing energy consumption, achieving precise process control, or meeting specific chemical reaction requirements, KINTEK has the expertise and equipment to meet your laboratory's unique needs.

Contact our experts today for a consultation and discover how our lab equipment solutions can optimize your process and total cost of ownership.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing

- What are the products of pyrolysis of wood? A Guide to Biochar, Bio-oil, and Syngas Yields

- What biomass is used in pyrolysis? Selecting the Optimal Feedstock for Your Goals

- What is the difference between calcining and roasting? A Guide to High-Temperature Processing

- What are the types of pyrolysis reactors used in industry? Choose the Right Technology for Your Product