In short, X-ray Fluorescence (XRF) is a cornerstone of modern environmental analysis due to its ability to rapidly and non-destructively detect hazardous elements, particularly heavy metals. This technique allows for immediate, on-site screening of soil, water, air, and consumer products, making it an indispensable tool for contamination assessment, regulatory compliance, and pollution monitoring.

The true environmental significance of XRF is not just what it measures, but how it measures. Its speed and portability enable real-time decision-making in the field, drastically accelerating the process of identifying and mitigating environmental risks compared to slower, more complex laboratory methods.

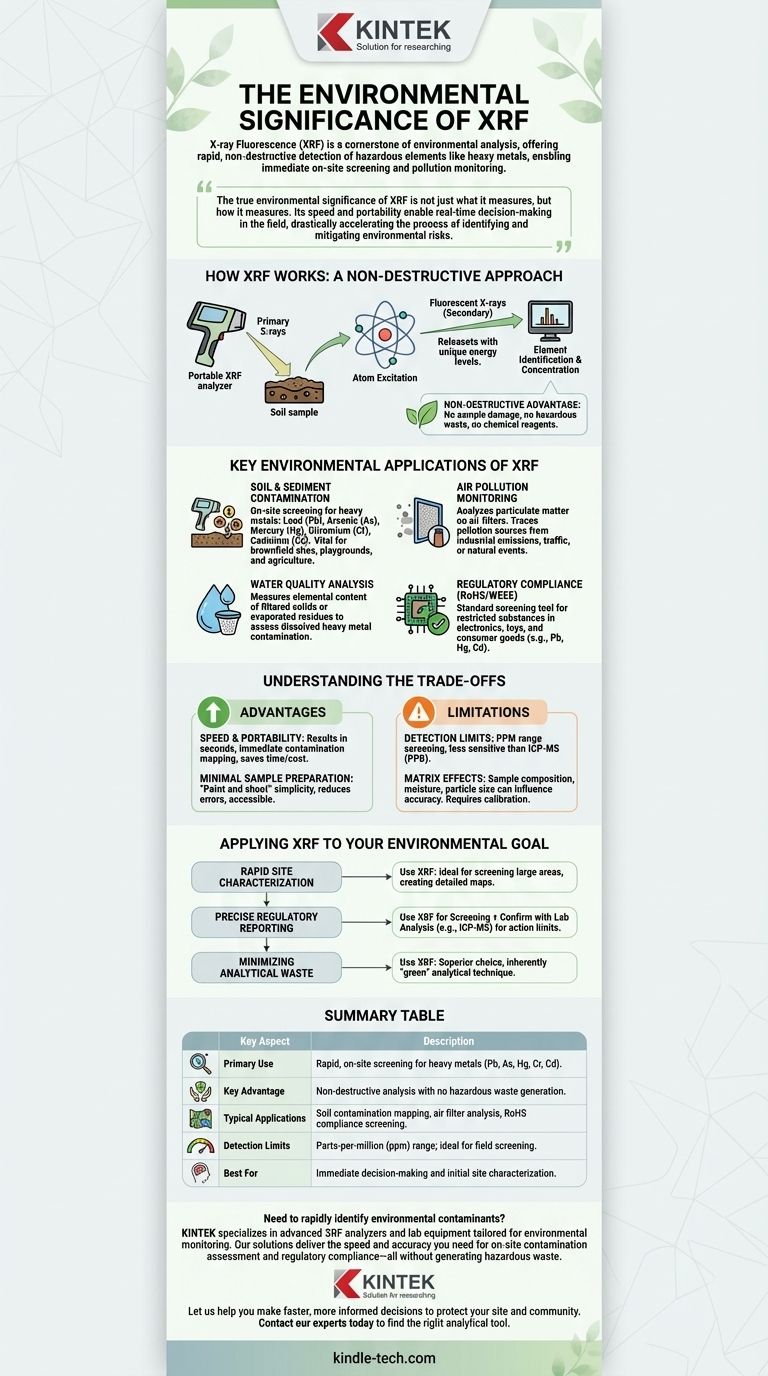

How XRF Works: A Non-Destructive Approach

XRF is an analytical technique used to determine the elemental composition of a material. It operates on a simple and elegant principle.

The Basic Principle

An XRF analyzer directs primary X-rays at a sample, causing atoms within the sample to become temporarily excited. To return to a stable state, these atoms release secondary X-rays, often called "fluorescence."

Each element emits fluorescent X-rays at a unique, characteristic energy level. The instrument's detector measures both the energy and intensity of these emissions, allowing it to identify which elements are present and in what concentration.

The Non-Destructive Advantage

Crucially, this entire process is non-destructive. The sample is not damaged or consumed during analysis. This is a significant environmental benefit in itself, as it eliminates the need for harsh acids or chemical reagents often used in traditional "wet chemistry" methods, thereby generating no hazardous waste.

Key Environmental Applications of XRF

XRF's versatility makes it a vital tool across numerous environmental domains. It provides the rapid data needed to assess risk, guide remediation efforts, and ensure public safety.

Soil and Sediment Contamination

This is one of the most common uses for XRF. Portable "handheld" XRF analyzers are used directly on-site to screen for heavy metal pollutants like lead (Pb), arsenic (As), mercury (Hg), chromium (Cr), and cadmium (Cd).

This capability is essential for evaluating industrial brownfield sites, checking for lead in playgrounds, and assessing agricultural soil quality.

Air Pollution Monitoring

Regulators use XRF to analyze particulate matter collected on air filters. By identifying the elemental composition of airborne dust and pollutants, scientists can trace pollution back to its source, whether it be industrial emissions, traffic, or natural events.

Water Quality Analysis

While XRF cannot directly analyze liquids, it is used to measure the elemental content of solids filtered out of water samples. It can also be used to analyze the dried residue left after evaporating a water sample, providing a rapid assessment of dissolved heavy metal contamination.

Regulatory Compliance (RoHS/WEEE)

XRF is the standard screening tool for regulations like the Restriction of Hazardous Substances (RoHS) directive. Manufacturers use it to quickly verify that electronics, toys, and other consumer goods do not contain restricted substances like lead, mercury, and cadmium above legal limits.

Understanding the Trade-offs

While powerful, XRF is not a universal solution. Understanding its advantages and limitations is key to using it effectively.

Advantage: Speed and Portability

The ability to get results in seconds, directly in the field, is XRF's greatest strength. This allows for the immediate mapping of contamination "hotspots" and saves immense time and cost compared to collecting samples and shipping them to a lab.

Advantage: Minimal Sample Preparation

For many applications, especially soil screening, you can simply "point and shoot." This simplicity reduces potential errors and makes the technology accessible to a wide range of users.

Limitation: Detection Limits

XRF is a screening tool. For many elements, its detection limits are in the parts-per-million (ppm) range. It is generally not as sensitive as laboratory methods like Inductively Coupled Plasma Mass Spectrometry (ICP-MS), which can measure down to parts-per-billion (ppb) or even lower.

Limitation: Matrix Effects

The accuracy of an XRF reading can be influenced by the sample's overall composition (the "matrix"). Factors like high moisture content, variable particle size, and the presence of interfering elements can skew results. Proper calibration and sample preparation techniques can mitigate this but must be considered.

Applying XRF to Your Environmental Goal

Your strategy for using XRF should align directly with your objective.

- If your primary focus is rapid site characterization: XRF is the ideal technology. Use a portable analyzer to quickly screen large areas and create detailed contamination maps to guide further action.

- If your primary focus is precise regulatory reporting: Use XRF for initial screening, but confirm any results that are close to a regulatory action limit with confirmatory laboratory analysis (e.g., ICP-MS).

- If your primary focus is minimizing analytical waste: XRF is a superior choice. Its non-destructive nature makes it an inherently "green" analytical technique compared to methods requiring chemical digestion.

By understanding its role as a powerful field-screening tool, you can leverage XRF to make faster and more informed decisions to protect the environment.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Use | Rapid, on-site screening for heavy metals (Pb, As, Hg, Cr, Cd) |

| Key Advantage | Non-destructive analysis with no hazardous waste generation |

| Typical Applications | Soil contamination mapping, air filter analysis, RoHS compliance screening |

| Detection Limits | Parts-per-million (ppm) range; ideal for field screening |

| Best For | Immediate decision-making and initial site characterization |

Need to rapidly identify environmental contaminants?

KINTEK specializes in providing advanced XRF analyzers and lab equipment tailored for environmental monitoring. Our solutions deliver the speed and accuracy you need for on-site contamination assessment, regulatory compliance (like RoHS), and pollution control—all without generating hazardous waste.

Let us help you make faster, more informed decisions to protect your site and community. Contact our experts today to find the right analytical tool for your specific environmental goals.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What advantages does torrefaction equipment offer for processing digestate? Unlock High-Value Energy Recovery

- What is the characterization of bio-oil? A Deep Dive into Its Properties and Potential

- What is the use of sputter coating? Achieve Superior Thin-Film Deposition for Your Lab

- What is the primary function of a laboratory centrifuge? Master PAAMP-b-PVK Block Copolymer Purification

- Why is a high-power ultrasonic homogenizer essential for cellulose-graphene hybrids? Unlock Superior Material Uniformity

- What are the advantages and disadvantages of bio-oil? A Guide to This Renewable Fuel

- Why is laboratory stirring equipment essential in the Sol-Gel process? Achieving Chemical Homogeneity and Stability

- What are the factors affecting heat transfer efficiency? Optimize Your Thermal Management System