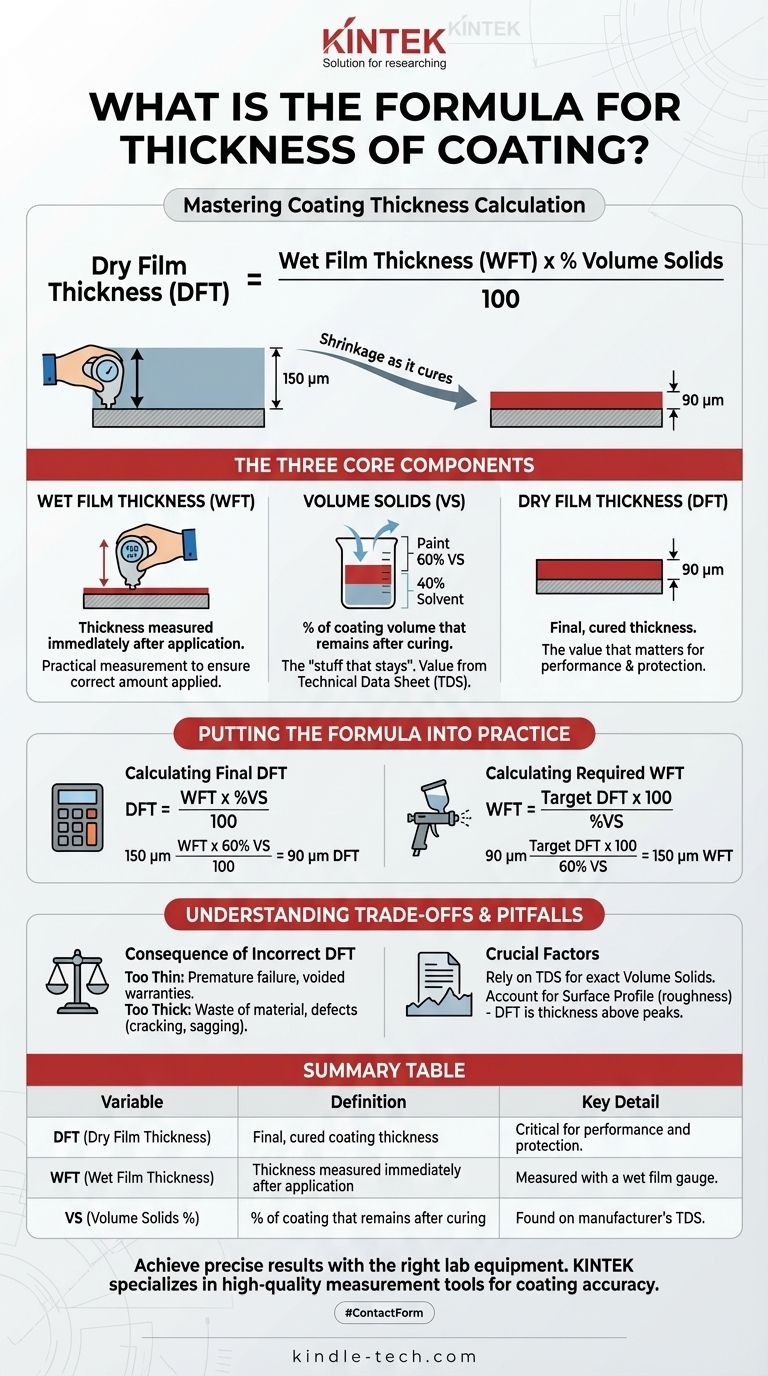

The primary formula for calculating a coating's final thickness from its wet application is Dry Film Thickness (DFT) = (Wet Film Thickness (WFT) x % Volume Solids) / 100. This calculation is essential because all coatings shrink as they cure. The formula allows you to predict the final, protective thickness based on the thickness you measure immediately after application.

The thickness of a wet coating is not its final thickness. The crucial factor is Volume Solids (VS)—the percentage of the coating that remains after all solvents evaporate. Understanding this relationship is key to meeting any performance specification.

The Three Core Components of the Formula

To use the formula effectively, you must understand each of its parts. The calculation is a direct relationship between the wet state, the dry state, and the non-volatile content of the coating itself.

What is Wet Film Thickness (WFT)?

Wet Film Thickness (WFT) is the thickness of the coating measured immediately after it has been applied to a surface.

It is measured using a simple tool called a wet film gauge. This is the most practical measurement to take during the application process to ensure the correct amount of material is being applied.

What is Volume Solids (VS)?

Volume Solids (VS) is the percentage of the coating's volume that is left behind after it has fully cured. The other part, the solvent, simply evaporates.

Think of it as the "stuff that stays." A paint with 60% Volume Solids means 40% of its wet volume will disappear into the air. This value is provided by the manufacturer on the product's Technical Data Sheet (TDS).

What is Dry Film Thickness (DFT)?

Dry Film Thickness (DFT) is the final, cured thickness of the coating. This is the value that matters for performance and protection.

Project specifications for corrosion resistance or fireproofing are always written in terms of DFT. It is the true measure of the protective barrier you have applied.

Putting the Formula into Practice

While there is one core relationship, you will use it in two ways: predicting the final DFT or, more commonly, determining how much wet paint to apply to meet a specification.

Calculating the Final DFT

This is the most direct use of the formula, answering the question of what you'll be left with after the coating dries.

Formula: DFT = (WFT x %VS) / 100

Example: If you apply a coating at 150 microns WFT and its Technical Data Sheet lists 60% Volume Solids, the final thickness will be 90 microns DFT. (150 x 60 / 100 = 90)

Calculating the Required WFT

This is the more practical, day-to-day calculation for an applicator. You know the target DFT from the specification and must determine what to aim for while spraying.

Formula: WFT = (Target DFT x 100) / %VS

Example: If a project requires a 90 micron DFT and you are using a paint with 60% Volume Solids, you must apply it at 150 microns WFT. (90 x 100 / 60 = 150)

Understanding the Trade-offs and Pitfalls

Simply knowing the formula is not enough. Understanding the consequences of getting it wrong is critical for avoiding costly failures.

The Consequence of Incorrect DFT

A coating's performance is directly tied to its thickness.

If the DFT is too thin, it will not provide the intended corrosion protection, leading to premature failure and voided warranties.

If the DFT is too thick, it is a waste of material and money. It can also lead to film defects like cracking, sagging, or improper curing.

Relying on the Technical Data Sheet (TDS)

The Volume Solids value is not a guess. It is a specific property of the paint formulation determined by the manufacturer.

Always use the VS percentage listed on the official TDS for the exact product you are using. Using an incorrect value will make all your calculations meaningless.

Overlooking Surface Profile

On rough surfaces, such as those prepared by abrasive blasting, the first layer of paint fills the "valleys" of the surface profile.

The DFT measurement that matters for protection is the thickness above the "peaks" of this profile. This must be accounted for when specifying and measuring the coating.

How to Apply This to Your Project

Use this knowledge to ensure your coating application is precise, efficient, and meets all performance requirements.

- If your primary focus is meeting a project specification: Always start with the required DFT from the technical documents and use the formula to calculate the target WFT you must apply.

- If your primary focus is quality control during application: Use a wet film gauge frequently as you work to ensure you are consistently applying the calculated WFT across the entire surface.

- If your primary focus is estimating material costs: Use the DFT, Volume Solids, and total area to accurately calculate the total volume of paint required, ensuring you account for waste.

Mastering this simple calculation transforms coating application from guesswork into a precise, repeatable science.

Summary Table:

| Variable | Definition | Key Detail |

|---|---|---|

| DFT (Dry Film Thickness) | Final, cured coating thickness | The critical measurement for performance and protection. |

| WFT (Wet Film Thickness) | Thickness measured immediately after application | Measured with a wet film gauge during application. |

| VS (Volume Solids %) | Percentage of coating volume that remains after curing | Found on the manufacturer's Technical Data Sheet (TDS). |

Achieve precise, cost-effective coating results with the right lab equipment.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our high-quality wet film gauges and other measurement tools help applicators and quality control professionals ensure coating thickness accuracy, prevent material waste, and guarantee project specifications are met.

Contact us today (#ContactForm) to find the perfect tools for your application and take the guesswork out of your coating process!

Visual Guide

Related Products

- Laboratory CVD Boron Doped Diamond Materials

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Electrolytic Electrochemical Cell for Coating Evaluation

- Custom PTFE Teflon Parts Manufacturer for Hollow Etching Flower Basket ITO FTO Developing Glue Removal

People Also Ask

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What physical conditions does an HPHT press provide for BDD synthesis? Achieve Extreme 5 GPa & 1800 K Conditions

- What is the role of an HFCVD reactor in synthesizing boron-doped diamond? Expert Guide to Diamond Gas Activation

- What is the carbon footprint of diamond mining? Uncovering the True Environmental and Ethical Cost

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods