In short, the primary function of a laboratory grinding mill is to reduce the size of solid samples. These instruments use various mechanical forces to crush, grind, and pulverize materials into smaller, more uniform particles, ranging from coarse granules to fine powders, in a controlled laboratory setting.

The immediate function of a mill is size reduction, but its deeper purpose is critical sample preparation. By creating smaller, more uniform particles, you enable more accurate analysis, faster chemical reactions, and consistent product formulation.

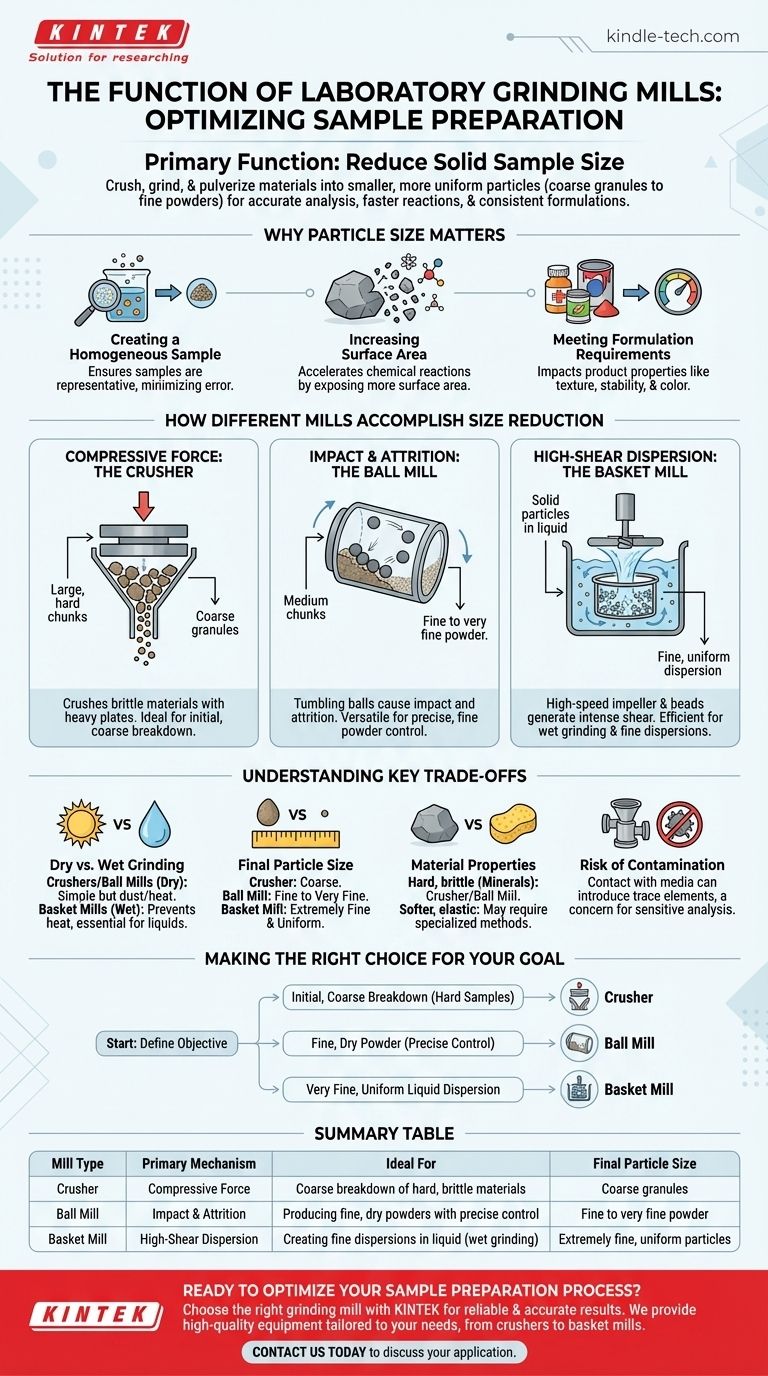

The Core Goal: Why Particle Size Matters

Before examining the mechanics of different mills, it's essential to understand why controlling particle size is a fundamental step in so many scientific and industrial processes.

Creating a Homogeneous Sample

Grinding a heterogeneous material into a fine powder ensures that any small sub-sample taken for analysis is truly representative of the whole batch. This minimizes sampling error and is crucial for obtaining accurate and repeatable results.

Increasing Surface Area

Chemical reactions occur on the surface of a material. By breaking a large particle into many smaller ones, you dramatically increase the total surface area available to react, leading to faster and more complete reactions.

Meeting Formulation Requirements

In fields like pharmaceuticals, paints, and food science, the particle size of an ingredient directly impacts the final product's properties. This can include its texture, stability, color, and bioavailability. Grinding mills are used to achieve these precise specifications.

How Different Mills Accomplish Size Reduction

While the goal is the same, different mills use distinct physical principles to break down materials. The method you choose depends on the material's properties and the desired final particle size.

Compressive Force: The Crusher

A laboratory crusher uses two heavy plates, one fixed and one moving in a rocking or gyrating motion. Material fed into the top is compressed between the plates, causing it to fracture.

As the crushed material becomes smaller, it moves down the funnel-shaped chamber and is subjected to repeated compression until it is small enough to exit through the narrow discharge gap at the bottom. This method is ideal for the initial, coarse breakdown of hard and brittle materials.

Impact and Attrition: The Ball Mill

A ball mill consists of a hollow jar filled with the sample material and grinding media, typically ceramic or steel balls. The jar is rotated, causing the balls to tumble and cascade.

Size reduction occurs through two actions: impact (as balls fall and strike the material) and attrition (as balls slide past each other, grinding the material trapped between them). By adjusting the rotation speed and the size of the balls, you can precisely control the final fineness of the powder.

High-Shear Dispersion: The Basket Mill

The basket mill is a high-speed, high-efficiency system often used for wet grinding—dispersing solid particles in a liquid. A central impeller creates a powerful vortex, sucking the material and liquid into a submerged grinding basket.

Inside the basket, a paddle agitates tiny, hard grinding beads (like zirconium) at high speed. This action generates intense shear and collision forces, rapidly milling the particles. The finely ground material is then expelled from the basket, creating a stable, fine dispersion.

Understanding the Key Trade-offs

Selecting a mill is not a one-size-fits-all decision. You must weigh the capabilities of each type against the specific demands of your sample and your analytical goals.

Dry Grinding vs. Wet Grinding

Crushers and most ball mills operate on dry materials. This is a straightforward process, but can generate dust and heat. Basket mills are designed for wet grinding, which can prevent overheating, reduce dust, and is essential for creating liquid dispersions like inks or paints.

Final Particle Size and Distribution

A crusher is a primary reduction tool and will only produce coarse material. A ball mill is highly versatile and can produce fine to very fine powders. A basket mill excels at producing extremely fine and uniform particles within a liquid medium very quickly.

Material Properties

Hard, brittle materials like minerals or ceramics are well-suited for crushers and ball mills. Softer, more elastic materials may be difficult to grind with these methods and might require specialized cryogenic grinding (not discussed here).

Risk of Contamination

All grinding involves physical contact between the mill components (plates, balls, beads) and the sample. This can introduce trace amounts of contamination from the grinding media itself. For ultra-sensitive elemental analysis, this is a critical factor to consider.

Making the Right Choice for Your Goal

To select the appropriate mill, start by defining the primary objective of your sample preparation.

- If your primary focus is the initial, coarse breakdown of hard, bulk samples: A gyratory or jaw crusher is the correct starting point.

- If your primary focus is producing a fine, dry powder with good control over particle size: A ball mill offers excellent versatility and precision for a wide range of materials.

- If your primary focus is creating a very fine, uniform dispersion of particles in a liquid: A basket mill is the specialized, high-efficiency tool designed for this exact purpose.

Ultimately, selecting the correct laboratory mill ensures your sample is properly prepared, which is the foundational step toward generating reliable and meaningful data.

Summary Table:

| Mill Type | Primary Mechanism | Ideal For | Final Particle Size |

|---|---|---|---|

| Crusher | Compressive Force | Coarse breakdown of hard, brittle materials | Coarse granules |

| Ball Mill | Impact & Attrition | Producing fine, dry powders with precise control | Fine to very fine powder |

| Basket Mill | High-Shear Dispersion | Creating fine dispersions in liquid (wet grinding) | Extremely fine, uniform particles |

Ready to optimize your sample preparation process?

Choosing the right grinding mill is the first step toward reliable and accurate analytical results. At KINTEK, we specialize in providing high-quality laboratory equipment and consumables tailored to your specific needs. Whether you require robust crushers for primary reduction, versatile ball mills for fine powders, or high-efficiency basket mills for liquid dispersions, our experts can help you select the perfect solution for your lab.

Contact us today to discuss your application and let KINTEK support your research with precision and reliability. Get in touch now!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Three-dimensional electromagnetic sieving instrument

- Laboratory Test Sieves and Sieving Machines

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- Can I use wet grinder for dry grinding? Avoid Damaging Your Kitchen Appliance

- What is the particle size of XRF sample preparation? Achieve Accurate & Repeatable Results

- What is the function of ultrasonic homogenizers in g-C3N4 preparation? Unlocking Maximum Catalytic Activity

- What is the use of a laboratory ball mill? Achieve Fine Grinding, Mixing & Material Synthesis

- How does a hammer mill work step by step? Master High-Impact Particle Size Reduction

- What is sample pulverizing? The Key to Accurate and Reliable Lab Analysis

- What is the grinding media in ball mills? Choose the Right Media for Optimal Grinding & Purity

- What is the process of media milling? Achieve Sub-Micron Particle Size Reduction