The future of biomass is one of strategic growth and diversification. It is moving beyond its traditional role of simple combustion and is poised to become a significant, versatile contributor to the global energy and materials portfolio. Projections show its potential expanding dramatically, with the United States alone potentially producing up to 1 billion dry tons annually for energy use by 2030, a substantial contribution to its renewable energy goals.

The core takeaway is that the future of biomass is not about replacing all other energy sources. Instead, its true potential will be unlocked by focusing on advanced conversion technologies that create high-value fuels and products from sustainable, non-food feedstocks like waste and algae.

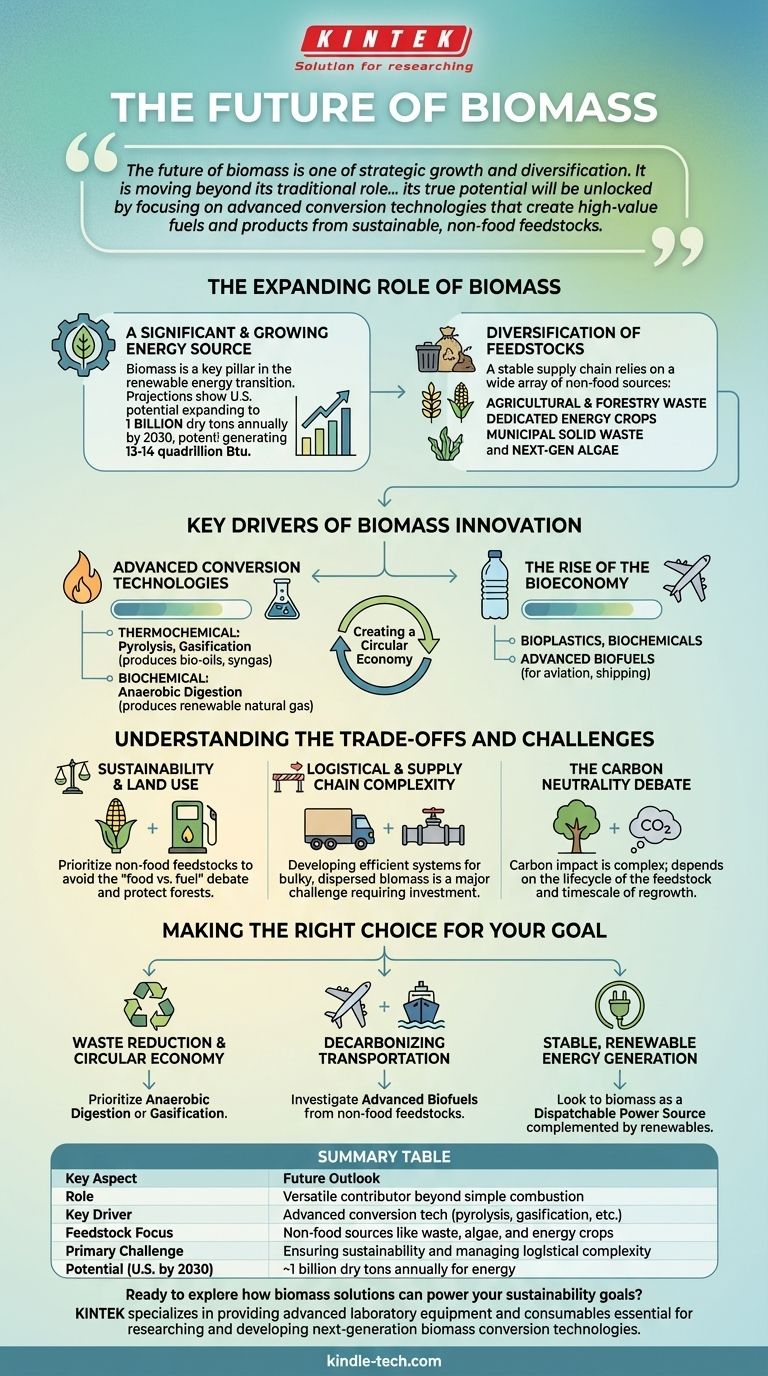

The Expanding Role of Biomass

The perception of biomass is shifting from a simple, rustic fuel to a sophisticated and flexible resource. Its future is tied to technological innovation and its ability to solve specific energy challenges.

A Significant and Growing Energy Source

Biomass is already a major source of renewable energy, and its contribution is set to grow. With anticipated advancements in agriculture and dedicated energy crops, its availability will increase significantly.

A projected annual availability of 1 billion dry tons in the U.S. could generate around 13–14 quadrillion Btu of energy. This represents a meaningful portion of total energy consumption, solidifying biomass as a key pillar in the renewable energy transition.

Diversification of Feedstocks

The future of biomass relies on a wide array of sources, known as feedstocks. This diversification is crucial for ensuring a stable and sustainable supply chain.

Key categories include agricultural and forestry waste, dedicated energy crops that don't compete with food, municipal solid waste, and next-generation sources like algae. This strategy turns waste streams into valuable resources.

Key Drivers of Biomass Innovation

Technological advancement is the engine powering the future of biomass. Innovation is focused not just on producing heat and power, but on creating a range of valuable products that support a circular economy.

Advanced Conversion Technologies

The most exciting developments are in conversion technologies, which transform raw biomass into refined fuels and chemicals. The industry is moving beyond direct combustion toward more efficient and versatile methods.

These include thermochemical conversion (like pyrolysis and gasification) to produce bio-oils and syngas, and biochemical conversion (like anaerobic digestion) to produce renewable natural gas.

The Rise of the Bioeconomy

Biomass is a cornerstone of the emerging bioeconomy, where renewable organic matter is the primary source for energy, materials, and chemicals.

This creates new industries and high-value products like bioplastics, biochemicals, and advanced biofuels for sectors like aviation, which are difficult to electrify.

Understanding the Trade-offs and Challenges

To realize its potential, the biomass industry must navigate significant challenges. An objective view of these hurdles is essential for sustainable development.

Sustainability and Land Use

The most critical concern is the "food vs. fuel" debate. The future of biomass hinges on using feedstocks that do not compete with food production or require deforestation.

Prioritizing agricultural residues, forestry byproducts, and waste materials is the most sustainable path forward. This approach strengthens the circular economy without placing new burdens on land and ecosystems.

Logistical and Supply Chain Complexity

Unlike fossil fuels that are easily piped or shipped, biomass is often bulky, dispersed, and has a lower energy density.

Developing efficient, cost-effective supply chains for collecting, transporting, and processing biomass at scale is a major logistical challenge that requires significant investment and planning.

The Carbon Neutrality Debate

While renewable, the carbon neutrality of biomass is complex. It depends entirely on the lifecycle of the feedstock.

Using waste that would otherwise decompose and release methane is clearly beneficial. However, the carbon impact of harvesting whole trees for energy is highly debated, as it depends on the timescale of forest regrowth.

Making the Right Choice for Your Goal

The value of biomass depends entirely on your objective. Its future applications are specialized, not one-size-fits-all.

- If your primary focus is waste reduction and the circular economy: Prioritize projects using anaerobic digestion or gasification to convert agricultural, forestry, or municipal waste into energy and bio-products.

- If your primary focus is decarbonizing transportation: Investigate the development of advanced biofuels from non-food feedstocks for use in aviation and heavy shipping.

- If your primary focus is stable, renewable energy generation: Look to biomass as a dispatchable power source that can complement intermittent renewables like solar and wind, especially when using sustainable local feedstocks.

Ultimately, the future of biomass lies not in its raw quantity, but in the intelligence and sustainability with which we choose to harness it.

Summary Table:

| Key Aspect | Future Outlook |

|---|---|

| Role | Versatile contributor to energy & materials, beyond simple combustion |

| Key Driver | Advanced conversion tech (pyrolysis, gasification, anaerobic digestion) |

| Feedstock Focus | Non-food sources like waste, algae, and energy crops |

| Primary Challenge | Ensuring sustainability and managing logistical complexity |

| Potential (U.S. by 2030) | ~1 billion dry tons annually for energy |

Ready to explore how biomass solutions can power your sustainability goals? KINTEK specializes in providing advanced laboratory equipment and consumables essential for researching and developing next-generation biomass conversion technologies. Whether you're working on pyrolysis, gasification, or biofuel analysis, our products support the innovation driving the bioeconomy. Contact our experts today to find the right tools for your lab's needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- What are the advantages and disadvantages of pyrolysis in solid waste management? A Guide to Waste-to-Resource Conversion

- What is the sputtering process in SEM? A Guide to Preventing Charging for Clear Imaging

- What is powder metallurgy summary? A Guide to Efficient, High-Precision Metal Parts

- What is vacuum sputtering? A Guide to Precision Thin-Film Deposition

- When was sputtering invented? From 1852 Discovery to 1920 Industrial Breakthrough

- Are carbon nanotubes safe to use? Understanding the Critical Difference Between Bound and Free CNTs

- What are the industrial applications of electron beam welding? Precision Welding for Critical Components

- What is the conductivity of graphite? Understanding Its High Electrical & Thermal Properties