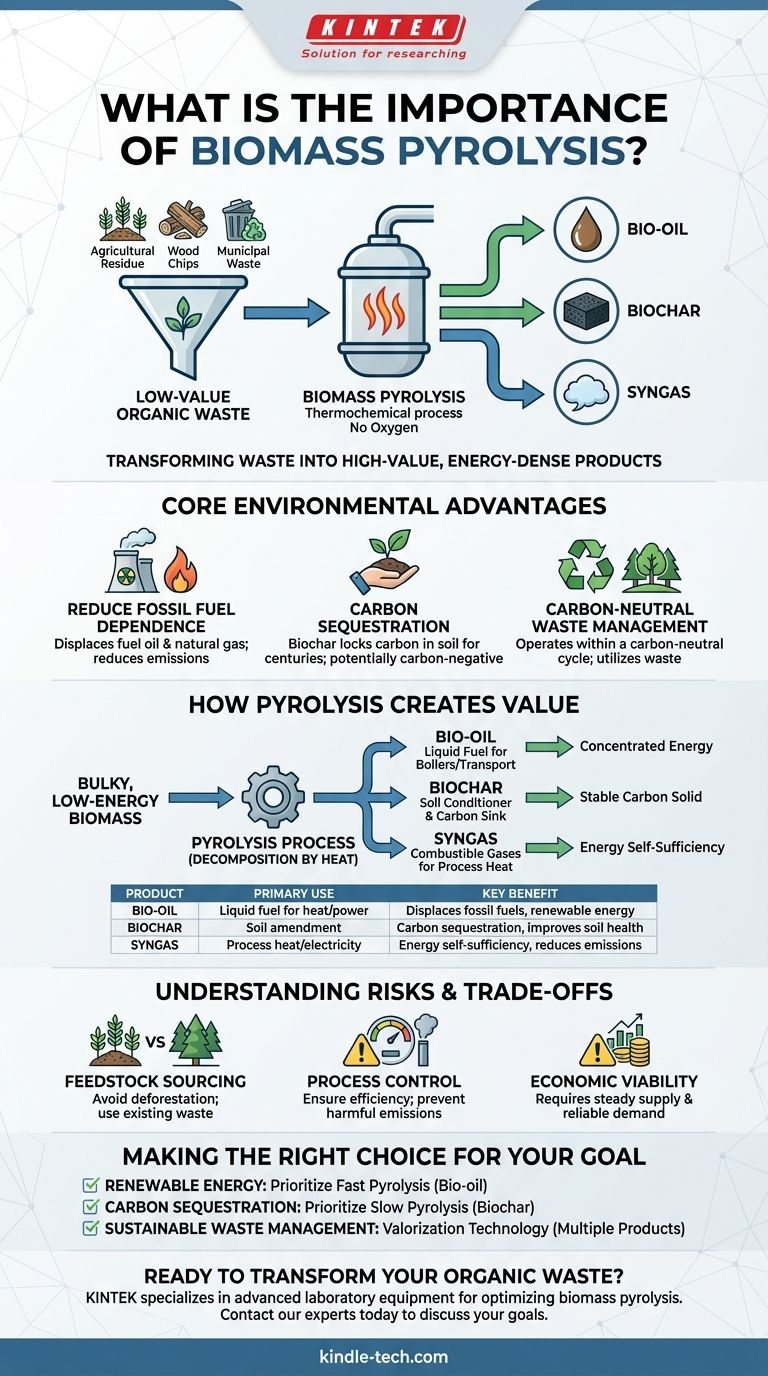

At its core, biomass pyrolysis is a critical technology because it transforms low-value organic waste into high-value, energy-dense products. It is a thermochemical process that heats biomass—such as agricultural residue, wood waste, or even municipal solid waste—in the absence of oxygen. This converts a bulky, often problematic material into valuable outputs like bio-oil, biochar, and syngas, providing a bridge between waste management and renewable resource creation.

The true importance of biomass pyrolysis lies in its versatility. It simultaneously offers a path to reduce dependence on fossil fuels, manage organic waste streams, and actively sequester carbon from the atmosphere, but its environmental and economic success hinges entirely on responsible implementation.

How Pyrolysis Creates Value from Waste

Pyrolysis is fundamentally a decomposition process driven by heat. By breaking down complex organic polymers in biomass without burning them, it unlocks the stored chemical energy and carbon in a more useful and stable form.

From Low-Energy Waste to High-Density Fuel

Much of raw biomass is bulky and has a low energy density, making it difficult to transport and use efficiently. Pyrolysis solves this by converting it into bio-oil, a liquid fuel that is much easier to store, handle, and use for generating heat or electricity.

This process effectively concentrates the energy from a large volume of waste into a smaller, more practical volume of liquid fuel.

Generating a Trio of Valuable Products

Pyrolysis does not produce just one output, but a suite of useful materials. The precise yield of each depends on the process conditions and feedstock.

- Bio-oil: A liquid that can be used as a boiler fuel, upgraded into transportation fuels, or serve as a source for specialty bio-chemicals.

- Biochar: A stable, carbon-rich solid that is an excellent soil conditioner, improving water retention and agricultural fertility. Critically, it sequesters carbon in the ground for centuries.

- Syngas: A mixture of combustible gases (primarily hydrogen and carbon monoxide) that can be looped back to provide the heat needed for the pyrolysis process itself, making the system more energy self-sufficient.

The Core Environmental Advantages

When managed correctly, pyrolysis offers significant environmental benefits that address several global challenges simultaneously.

Reducing Reliance on Fossil Fuels

The bio-oil and syngas produced can directly displace fossil fuels like fuel oil and natural gas in industrial heating and power generation. This reduces the pollution and greenhouse gas emissions associated with burning non-renewable resources.

A Powerful Tool for Carbon Sequestration

The production of biochar is one of the most compelling advantages of pyrolysis. When this biochar is added to soil, the carbon it contains is locked away, preventing it from returning to the atmosphere as CO2. This makes pyrolysis a potentially carbon-negative technology, meaning it can actively remove more CO2 from the atmosphere than it produces.

A Pathway for Carbon-Neutral Waste Management

By using waste materials—like agricultural residues or wood processing scraps that would otherwise decompose or be burned—pyrolysis operates within a carbon-neutral cycle. The CO2 released during the eventual use of its fuels is equivalent to the CO2 the original biomass absorbed from the atmosphere.

Understanding the Trade-offs and Risks

Like any technology, the benefits of pyrolysis are not automatic. Its impact is determined by how it is deployed, and there are critical factors to consider.

The Problem of Feedstock Sourcing

The single greatest risk is the source of the biomass. If dedicated crops are grown for pyrolysis in a way that leads to deforestation or competition with food crops, the process can cause more environmental harm than good. The most responsible approach relies exclusively on existing waste streams.

The Importance of Process Control

A poorly designed or operated pyrolysis unit can be inefficient and release harmful pollutants. Proper engineering and control are essential to ensure the process is clean and maximizes the yield of valuable products, preventing the escape of tars or other noxious compounds.

Economic Viability at Scale

While pyrolysis produces valuable products, the economic case depends on factors like feedstock cost, logistics, and local markets for bio-oil and biochar. Achieving profitability often requires a steady, low-cost supply of biomass and a reliable demand for the outputs.

Making the Right Choice for Your Goal

The optimal pyrolysis strategy depends entirely on your primary objective. Evaluate your project goals to determine your focus.

- If your primary focus is renewable energy generation: Prioritize fast pyrolysis conditions to maximize bio-oil yield for use in boilers or for upgrading to liquid fuels.

- If your primary focus is carbon sequestration and soil health: Prioritize slow pyrolysis conditions to maximize the production of stable, high-quality biochar for agricultural application.

- If your primary focus is sustainable waste management: Treat pyrolysis as a valorization technology, turning a disposal cost (e.g., for municipal or agricultural waste) into a revenue stream from multiple products.

When implemented thoughtfully, biomass pyrolysis serves as a powerful tool for building a more circular and sustainable economy.

Summary Table:

| Product | Primary Use | Key Benefit |

|---|---|---|

| Bio-oil | Liquid fuel for heat/power | Displaces fossil fuels, renewable energy |

| Biochar | Soil amendment | Carbon sequestration, improves soil health |

| Syngas | Process heat/electricity | Energy self-sufficiency, reduces emissions |

Ready to transform your organic waste streams into valuable resources?

KINTEK specializes in advanced laboratory equipment and consumables for analyzing and optimizing biomass pyrolysis processes. Whether you are developing renewable energy solutions, researching carbon sequestration with biochar, or creating sustainable waste management systems, our precise tools help you achieve reliable and efficient results.

Contact our experts today to discuss how our solutions can support your specific biomass pyrolysis goals and accelerate your project's success.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas