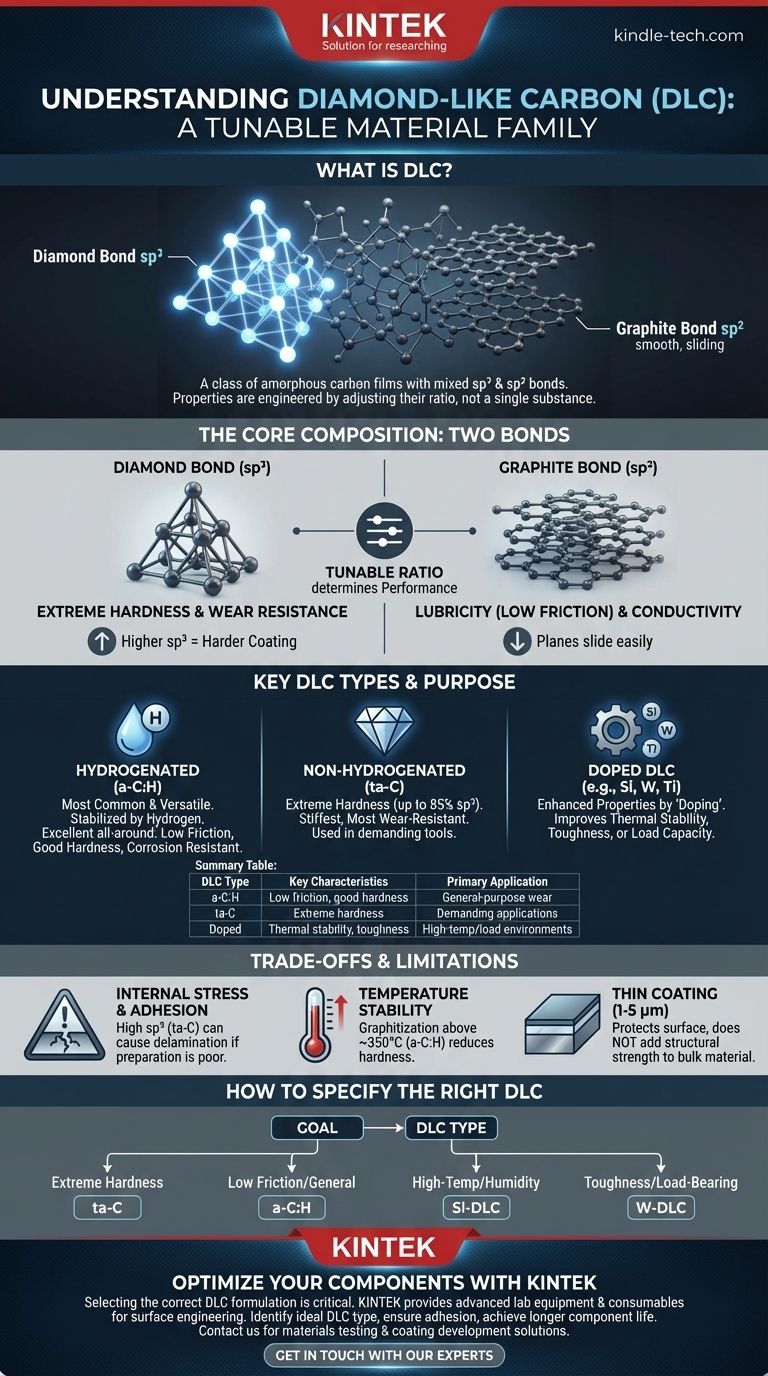

Diamond-Like Carbon (DLC) is not a single, monolithic material. Instead, it is a class of amorphous carbon films that exhibit some of the valuable properties of natural diamond. The "material" is fundamentally carbon, but its atoms are arranged in a disordered state that contains a mixture of diamond-type and graphite-type chemical bonds. This unique structure is what gives DLC its sought-after combination of hardness, low friction, and chemical resistance.

The core concept to grasp is that "DLC" describes a tunable family of coatings, not one specific substance. The properties of a DLC coating are determined by the ratio of its internal chemical bonds and the inclusion of other elements, allowing it to be engineered for specific applications like wear resistance or lubricity.

The Core Composition: A Tale of Two Bonds

To understand DLC, you must understand the two ways carbon atoms can bond. The balance between these two bond types dictates the final properties of the coating.

The Diamond Bond (sp³)

This is a tetrahedral bond, where one carbon atom is strongly linked to four others. This is the same type of bond found in natural diamond.

This structure is responsible for the extreme hardness, rigidity, and wear resistance associated with DLC. A higher percentage of sp³ bonds results in a harder, more "diamond-like" coating.

The Graphite Bond (sp²)

This is a trigonal planar bond, where a carbon atom is linked to three others in a flat plane. This is the bond structure found in graphite.

These bonds provide the properties of lubricity (low friction) and electrical conductivity. The planes can slide over one another easily, which is why graphite is a good dry lubricant.

It's All About the Ratio

A DLC film is an amorphous matrix containing a mixture of both sp³ and sp² bonded carbon atoms. The ratio of sp³ to sp² is the most critical factor defining the coating's performance. It is not a crystal like diamond, but a disordered network.

Key Types of DLC and Their Purpose

Engineers can manipulate the composition to create different "flavors" of DLC, each optimized for a different task.

Hydrogenated DLC (a-C:H)

This is the most common and cost-effective form of DLC. During the deposition process, hydrogen is incorporated into the amorphous carbon structure.

The hydrogen atoms help stabilize the random network and terminate "dangling" bonds. This generally results in an excellent all-around coating with very low friction, good hardness, and high corrosion resistance.

Non-Hydrogenated DLC (ta-C)

Often called tetrahedral amorphous carbon (ta-C), this form has a much higher percentage of diamond-like sp³ bonds (up to 85%). It contains little to no hydrogen.

This results in the hardest, stiffest, and most wear-resistant type of DLC, often approaching the properties of natural diamond. It is used in the most demanding applications, such as on cutting tools.

Doped DLC

To further tune the properties, other elements can be intentionally added (or "doped") into the film.

Common dopants include Silicon (Si), which can increase thermal stability and reduce internal stress, and metals like Tungsten (W) or Titanium (Ti), which can increase toughness and load-bearing capacity.

Understanding the Trade-offs and Limitations

While powerful, DLC is a specialized coating and not a universal solution. Understanding its limitations is critical for successful application.

Internal Stress and Adhesion

Coatings with a very high sp³ content, like ta-C, have high internal compressive stress. This can cause the coating to delaminate or peel off the substrate if the surface preparation and application process are not perfectly controlled.

Temperature Stability

DLC coatings have a limited operating temperature. At high temperatures (typically starting around 350°C for a-C:H), the hard sp³ bonds can begin to convert into softer sp² bonds in a process called graphitization. This causes the coating to lose its hardness and protective qualities.

It Is a Coating, Not a Bulk Material

This is a critical distinction. DLC is a very thin film (typically 1-5 microns) applied to the surface of a component. It protects the surface from wear and friction but does not add structural strength to the underlying part. The substrate material must be strong enough to support the load on its own.

How to Specify the Right DLC for Your Goal

Selecting the correct DLC requires matching the formulation to the primary engineering challenge.

- If your primary focus is extreme hardness and wear resistance: Specify a non-hydrogenated tetrahedral amorphous carbon (ta-C) coating for its high sp³ content.

- If your primary focus is low friction and general-purpose performance: A standard hydrogenated amorphous carbon (a-C:H) is the most versatile and cost-effective choice.

- If your primary focus is performance in high-temperature or high-humidity environments: Look for a silicon-doped DLC (Si-DLC), which offers superior thermal stability and lower friction in humid conditions.

- If your primary focus is toughness and load-bearing on softer substrates: A metal-doped DLC (like W-DLC) can provide better ductility and support.

By understanding DLC as a tunable platform rather than a single material, you can precisely select the right coating to solve your engineering challenge.

Summary Table:

| DLC Type | Key Characteristics | Primary Application |

|---|---|---|

| Hydrogenated (a-C:H) | Low friction, good hardness, corrosion resistant | General-purpose wear resistance |

| Non-Hydrogenated (ta-C) | Extreme hardness, high wear resistance | Demanding applications (e.g., cutting tools) |

| Doped (e.g., Si-DLC, W-DLC) | Enhanced thermal stability, toughness, or load capacity | High-temperature or high-load environments |

Optimize Your Components with the Right DLC Coating

Selecting the correct Diamond-Like Carbon formulation is critical for maximizing performance, whether your priority is extreme hardness, low friction, or thermal stability. KINTEK specializes in providing advanced lab equipment and consumables for surface engineering and coating analysis.

Our expertise can help you:

- Identify the ideal DLC type (a-C:H, ta-C, or doped) for your specific wear, friction, or environmental challenges.

- Ensure proper adhesion and performance by understanding substrate preparation and coating limitations.

- Achieve longer component life and improved efficiency with a precisely engineered surface solution.

Contact us today to discuss how our solutions can enhance your laboratory's capabilities in materials testing and coating development.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

People Also Ask

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- Is diamond coating worth it? Maximize Component Life and Performance