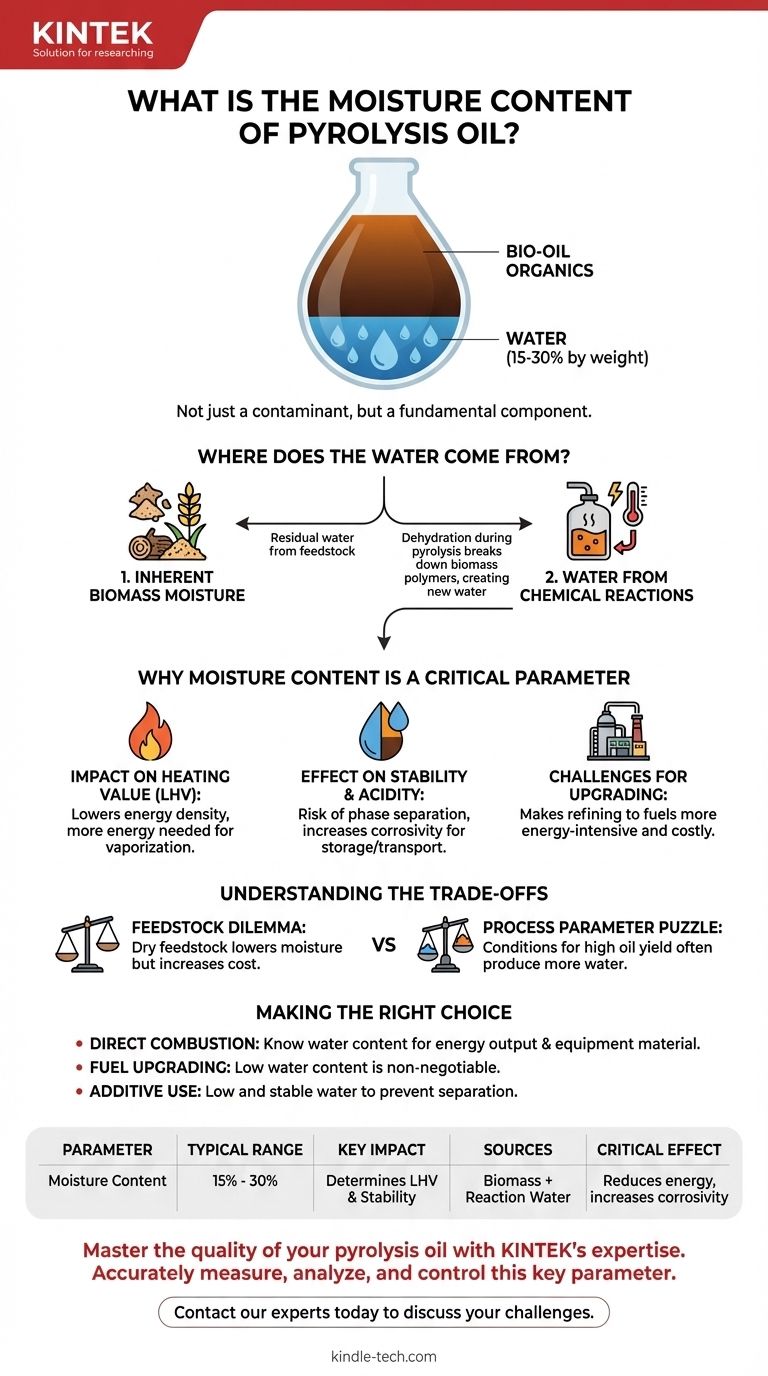

The moisture content of pyrolysis oil is not a single value, but typically ranges from 15% to 30% by weight. This water is not merely contamination; it is a fundamental component created during the pyrolysis process itself, originating from both the initial moisture in the biomass and chemical reactions that break down cellulose and hemicellulose. The exact percentage depends heavily on the type of biomass used and the specific parameters of the pyrolysis process.

The water in pyrolysis oil is an inherent byproduct of its creation, not just a contaminant. Understanding and managing its concentration is the most critical factor in determining the oil's energy value, stability, and viability for any application.

Where Does the Water Come From?

The significant water content in pyrolysis oil is a direct result of its production method. It originates from two distinct sources that are crucial to understand.

Inherent Moisture in the Biomass

All biomass, whether it's wood, crop residue, or other organic matter, naturally contains water. While pre-drying the feedstock can reduce this initial moisture, it is rarely eliminated completely. This residual water is carried over and becomes part of the final liquid product.

Water from Chemical Reactions

More significantly, water is actively created during the fast pyrolysis reaction. As the high temperatures break down the complex polymers in biomass (holocellulose), a process called dehydration occurs. This chemical reaction splits off hydrogen and oxygen atoms from the carbohydrate structures, which then combine to form new water molecules. This reaction-generated water becomes intimately mixed with the organic compounds, forming the "aqueous solution" that constitutes a large part of the oil.

Why Moisture Content is a Critical Parameter

The percentage of water is not just a number; it directly dictates the oil's fundamental properties and its suitability for use.

Impact on Heating Value

Water does not burn. Therefore, a higher water content directly lowers the Lower Heating Value (LHV) of the pyrolysis oil. More energy is required to vaporize the water before the organic components can combust, reducing the net energy released. An oil with 30% water has significantly less usable energy per kilogram than one with 15% water.

Effect on Stability and Acidity

Pyrolysis oil is a complex micro-emulsion, as noted in the references. High water content can lead to phase separation over time, where the oil separates into a watery aqueous phase and a thick, lignin-rich organic phase. This makes storage and transport difficult. Furthermore, water contributes to the oil's high acidity and corrosive nature, posing a challenge for standard pipes, pumps, and storage tanks.

Challenges for Upgrading

If the goal is to refine pyrolysis oil into higher-value products like transportation fuels (a process called upgrading), water is a major problem. Most upgrading processes, such as hydrotreating, require the removal of both water and oxygen. A higher initial water content makes this upgrading process more energy-intensive and expensive.

Understanding the Trade-offs

Controlling water content involves balancing competing factors in the production process. There is no "perfect" setting, only a series of trade-offs.

The Feedstock Dilemma

Using a very dry biomass feedstock (e.g., kiln-dried wood) will result in a lower-moisture oil. However, the energy and cost required to extensively dry the feedstock can reduce the overall energy efficiency and economic viability of the entire process.

The Process Parameter Puzzle

Optimizing pyrolysis process parameters like temperature and vapor residence time is a balancing act. Certain conditions might maximize the total liquid oil yield but also produce more reaction water, leading to a lower-quality oil. Conversely, conditions that produce a "drier" oil might result in a lower overall yield, producing more non-condensable gases or char instead.

Making the Right Choice for Your Application

The acceptable level of moisture is entirely dependent on your end goal.

- If your primary focus is direct combustion for heat (in a boiler or furnace): You must know the water content to accurately calculate the fuel's energy output and ensure your equipment is made of materials that can withstand its corrosive properties.

- If your primary focus is upgrading to transportation fuels or chemicals: A lower water content is non-negotiable, as high moisture dramatically increases the cost and complexity of the necessary refining steps.

- If your primary focus is using it as an additive (e.g., in asphalt or resins): The water content must be low and stable to prevent phase separation and ensure proper mixing and long-term performance of the final product.

Ultimately, mastering the use of pyrolysis oil begins with a clear understanding of its water content and the profound impact it has on every aspect of its performance.

Summary Table:

| Parameter | Typical Range | Key Impact |

|---|---|---|

| Moisture Content | 15% - 30% by weight | Directly determines Lower Heating Value (LHV) and stability |

| Primary Sources | Biomass inherent moisture + Chemical reaction water | Defines oil's fundamental composition as an aqueous solution |

| Critical Effect | Reduces energy density; Increases corrosivity & risk of phase separation | Dictates suitability for combustion, upgrading, or chemical use |

Master the quality of your pyrolysis oil with KINTEK's expertise. The moisture content of your bio-oil is the single most critical factor for its energy value and stability. Whether you're focused on direct combustion, fuel upgrading, or chemical production, our specialized lab equipment and consumables help you accurately measure, analyze, and control this key parameter.

Let us provide the reliable solutions you need to optimize your process and ensure your fuel meets application requirements. Contact our experts today to discuss your specific biomass and pyrolysis challenges.

Visual Guide

Related Products

- Filter Testing Machine FPV for Dispersion Properties of Polymers and Pigments

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Infrared Heating Quantitative Flat Plate Press Mold

- Three-dimensional electromagnetic sieving instrument

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- Why are PTFE beakers required for hafnium metal ICP-OES validation? Ensure Pure Sample Dissolution

- How do you test a lithium battery to see if it's good? A Guide to Measuring Voltage, Capacity & Health

- What is the significance of compression set? Predict Material Failure and Ensure Long-Term Reliability

- What are the advantages of using PTFE filters for ionic component analysis? Ensure Accurate Sample Quantification

- How do you test the capacity of a lithium-ion battery? A Guide to Accurate Measurement