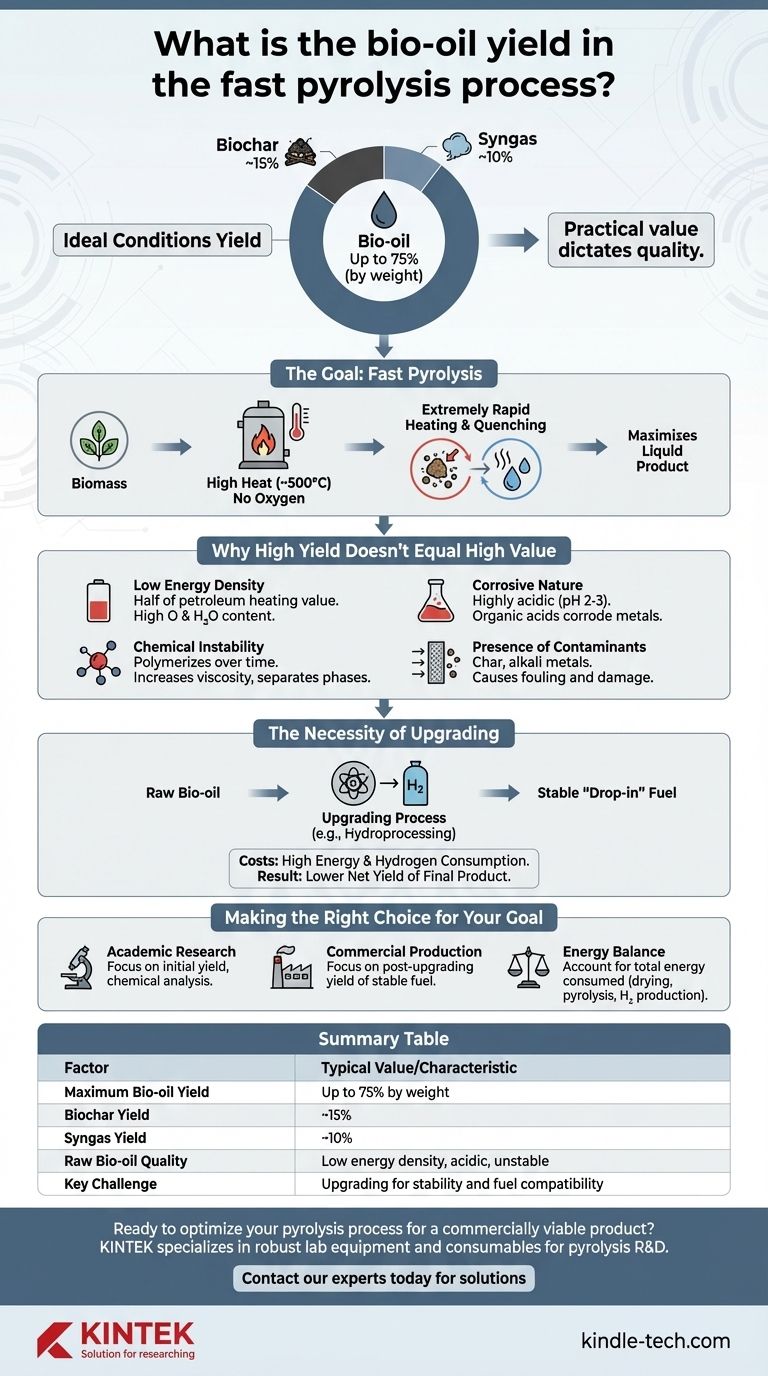

Under ideal conditions, the fast pyrolysis of biomass can convert a significant portion of the feedstock into a liquid product known as bio-oil. A well-optimized process typically yields up to 75% bio-oil by weight, with the remainder being converted into biochar (around 15%) and non-condensable syngas (around 10%). However, the practical value of this yield is dictated entirely by the quality of the resulting oil.

The central challenge of fast pyrolysis is not achieving a high liquid yield, but rather managing the unstable and corrosive nature of the raw bio-oil. The initial high yield is only the starting point for a necessary and energy-intensive upgrading process to create a viable fuel.

The Goal of Fast Pyrolysis

Fast pyrolysis is a thermochemical conversion process designed to maximize the liquid product from biomass. It operates on a few key principles.

High Heat, No Oxygen

The process involves heating biomass to temperatures of around 500°C in the complete absence of oxygen. This prevents combustion and instead causes the complex organic polymers (like cellulose and lignin) to break down into smaller, volatile molecules.

Extremely Rapid Heating and Quenching

To maximize the liquid yield, the heating of the biomass particles must be incredibly fast. Just as crucial is the rapid cooling, or "quenching," of the resulting hot vapors. This locks the molecules in their liquid state as bio-oil before they can break down further into non-condensable gases.

Why High Yield Doesn't Equal High Value

Achieving a 75% liquid yield is an impressive feat of chemical engineering, but the raw bio-oil produced is fundamentally different from conventional petroleum crude. Its inherent properties present significant technical and economic hurdles.

Low Energy Density

The heating value of raw bio-oil is only about half that of traditional petroleum-based fuels. This is primarily due to its high oxygen (35-40%) and water (15-30%) content, which do not contribute to combustion.

Corrosive Nature

Bio-oil is highly acidic, often with a pH between 2 and 3. This is due to the presence of organic acids, such as acetic and formic acid, which makes it highly corrosive to common construction metals like carbon steel.

Chemical Instability

Over time, the reactive compounds within bio-oil can continue to polymerize, leading to an increase in viscosity, phase separation, and the formation of solids. This makes long-term storage and transportation a major challenge.

Presence of Contaminants

Bio-oil can contain various contaminants, including char particles and alkali metals from the original biomass. These must be removed before the oil can be used in engines or refineries, as they can cause fouling and damage equipment.

Understanding the Trade-offs: The Necessity of Upgrading

The raw, high-yield bio-oil is rarely usable in its initial state. To become a viable "drop-in" fuel, it must undergo significant and costly processing.

The Upgrading Process

Upgrading techniques are designed to stabilize the oil and improve its properties. The most common method is hydroprocessing (or hydrotreating), which uses a catalyst and high-pressure hydrogen to remove oxygen, reduce acidity, and increase the energy density.

The Impact on Net Yield

While upgrading is essential, it comes at a cost. The process consumes a significant amount of energy and expensive hydrogen. More importantly, removing oxygen and other atoms reduces the final volume of the usable fuel, meaning the net yield of the final product is much lower than the initial 75% figure.

Making the Right Choice for Your Goal

Evaluating the bio-oil yield from fast pyrolysis requires looking beyond the initial number and considering the entire production chain.

- If your primary focus is academic research: Maximizing the initial liquid yield is a valid goal, but it should be paired with a detailed chemical analysis to understand the composition and potential for upgrading.

- If your primary focus is commercial production: The final, post-upgrading yield of a stable, specification-compliant fuel is the only metric that matters for economic viability.

- If your primary focus is energy balance: You must account for the energy consumed during biomass drying, pyrolysis, and especially the hydrogen production and compression required for upgrading.

Ultimately, the success of fast pyrolysis hinges on the ability to efficiently convert the high initial yield into a stable, energy-dense, and economically competitive final product.

Summary Table:

| Factor | Typical Value/Characteristic |

|---|---|

| Maximum Bio-oil Yield | Up to 75% by weight |

| Biochar Yield | ~15% |

| Syngas Yield | ~10% |

| Raw Bio-oil Quality | Low energy density, acidic, unstable |

| Key Challenge | Upgrading for stability and fuel compatibility |

Ready to optimize your pyrolysis process for a commercially viable product?

The high initial yield of bio-oil is just the beginning. Success depends on efficiently managing the entire process, from feedstock preparation to the crucial upgrading stage. KINTEK specializes in providing robust lab equipment and consumables for pyrolysis research and development, helping you analyze, optimize, and scale your bio-oil production.

Let's discuss your project goals. Contact our experts today to find the right solutions for your laboratory's needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products