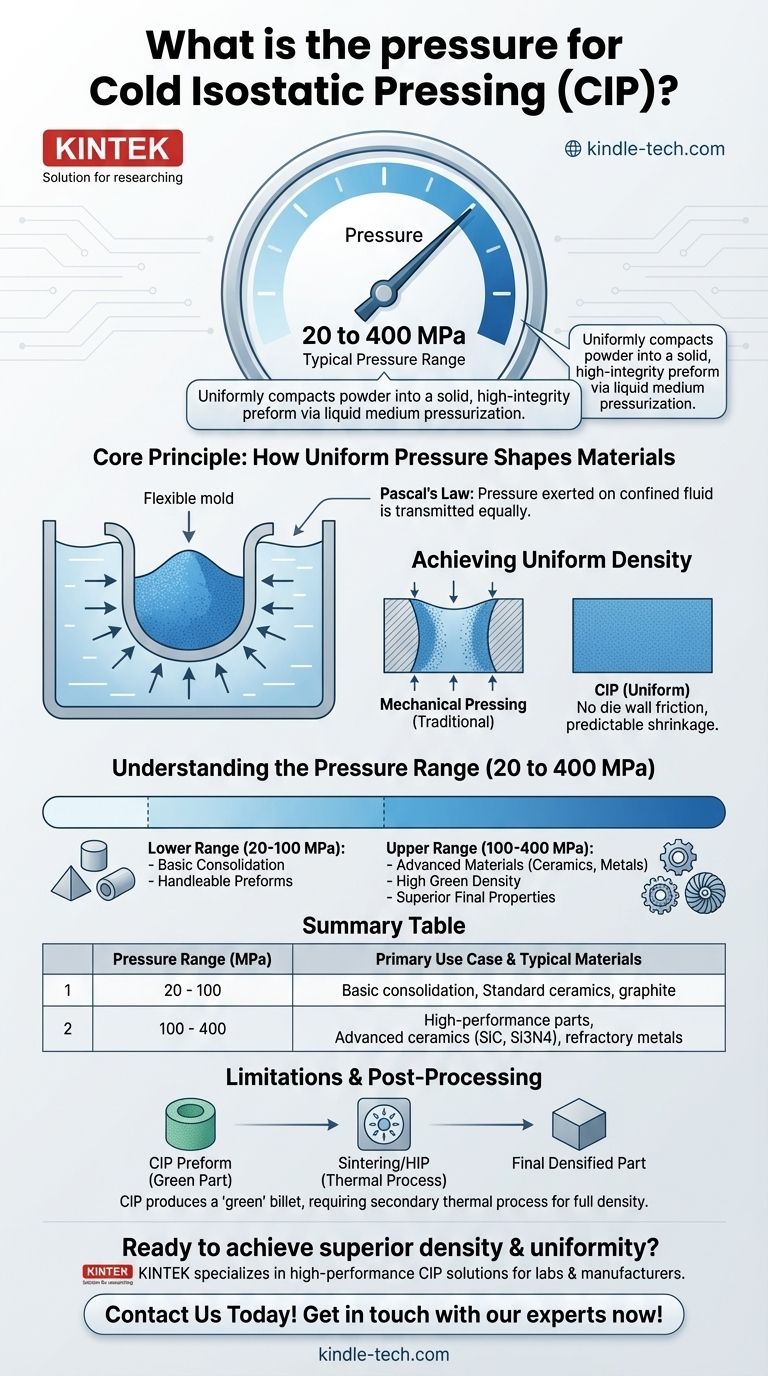

The typical pressure range for cold isostatic pressing (CIP) is between 20 and 400 MPa. This process involves submerging a powder-filled, flexible mold into a liquid medium, which is then pressurized to uniformly compact the powder into a solid, high-integrity preform.

The key to understanding cold isostatic pressing is not just the high pressure, but how that pressure is applied. By using a liquid, CIP exerts perfectly uniform force from all directions, creating a material preform with exceptional density and structural consistency that is difficult to achieve with traditional mechanical pressing.

The Core Principle: How Uniform Pressure Shapes Materials

Cold isostatic pressing leverages a fundamental principle of fluid dynamics—Pascal's Law—which states that pressure exerted on a confined fluid is transmitted equally in all directions. This is the source of its primary advantages.

The Role of the Fluid Medium

The process uses a liquid, typically water mixed with a corrosion inhibitor, as the pressure-transmitting medium. An external pump pressurizes this fluid inside a robust chamber.

Because the pressure is delivered through a liquid, every surface of the flexible mold experiences the exact same force, eliminating the pressure gradients and internal stresses common in uniaxial (one-direction) pressing.

Achieving Uniform Density

This uniform pressure application is the direct cause of the resulting part's highly uniform density.

In mechanical pressing, friction with the die walls can cause density variations within the part. CIP avoids this entirely, resulting in predictable, even shrinkage during the subsequent firing or sintering stage.

Forming Complex and Large Shapes

Since the "die" is a flexible mold and the pressure is hydrostatic, CIP is exceptionally versatile. It can produce very large parts or parts with complex geometries that would be impractical or impossible to create with rigid dies.

Understanding the Pressure Range (20 to 400 MPa)

The specific pressure used within this wide range is determined by the material being processed and the desired final density of the preform, often called the "green" part.

The Lower End: Basic Consolidation

Pressures in the lower range (e.g., 20-100 MPa) are sufficient for consolidating less demanding powders or when the primary goal is simply to create a handleable preform for further processing.

The Upper End: Advanced Materials

High pressures, approaching 400 MPa, are necessary for compacting very hard or fine powders, such as advanced ceramics like silicon nitride and silicon carbide.

This extreme pressure is required to overcome the inter-particle resistance and achieve a high "green density," which is critical for producing a high-performance final component.

The Impact on the Final Product

Higher CIP pressures directly lead to preforms with greater integrity. These dense parts exhibit minimal distortion or cracking during firing and have improved mechanical properties, strength, and corrosion resistance in their final, sintered state.

Practical Applications and Trade-offs

CIP is not a universal solution; it is a specialized tool chosen for its specific benefits in powder metallurgy and technical ceramics.

Key Materials Processed with CIP

This technology is essential for producing high-quality components from materials such as:

- Advanced ceramics (silicon carbide, silicon nitride, boron carbide)

- Graphite and refractory materials

- Electrical insulators

- Refractory metals

When to Choose CIP Over Other Methods

CIP is often selected when the high initial cost of manufacturing rigid pressing dies cannot be justified, such as for small production runs or prototyping. It is also the preferred method for parts that are too large or geometrically complex for conventional presses.

Limitations to Consider

It is crucial to understand that CIP produces a preform or "green" billet, not a finished part. The compacted powder has good integrity but has not yet been fully densified.

A secondary thermal process, such as sintering or hot isostatic pressing (HIP), is almost always required to bond the particles together and achieve the final desired material properties and full density.

Making the Right Choice for Your Goal

Selecting the appropriate pressure and process depends entirely on your material and end-use requirements.

- If your primary focus is basic consolidation of a standard powder: A lower pressure range may be sufficient and more cost-effective to create a handleable preform.

- If your primary focus is producing high-performance technical ceramics: A high-pressure CIP cycle is necessary to achieve the high green density required for superior final properties.

- If your primary focus is cost-effective prototyping or forming large, complex shapes: CIP is an ideal choice, as it avoids the high cost and geometric limitations of rigid die sets.

By applying pressure hydrostatically, cold isostatic pressing empowers you to create superior material preforms with unmatched uniformity.

Summary Table:

| Pressure Range (MPa) | Primary Use Case | Typical Materials |

|---|---|---|

| 20 - 100 | Basic powder consolidation, handleable preforms | Standard ceramics, graphite |

| 100 - 400 | High-performance parts, high green density | Advanced ceramics (SiC, Si3N4), refractory metals |

Ready to achieve superior density and uniformity in your advanced ceramics or metal powders?

At KINTEK, we specialize in providing high-performance cold isostatic pressing solutions for laboratories and manufacturers. Our expertise ensures you get the precise pressure control needed to create high-integrity preforms with exceptional structural consistency.

Contact us today to discuss how our CIP equipment and consumables can enhance your material processing and deliver the high-quality results you need.

Get in touch with our experts now!

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- What are the functions of stainless steel capsules in HIP synthesis of Li2MnSiO4? Key Roles in Crystal Growth

- What does hot isostatic pressing do? Eliminate Internal Flaws for Superior Part Performance

- How does Cold Isostatic Press (CIP) technology help in suppressing lithium dendrite growth? Enhance Battery Safety.

- How does a Hot Isostatic Press (HIP) machine improve AlFeTiCrZnCu alloys? Achieving 10 GPa Hardness and Maximum Density

- What is a cold press machine? A Guide to Uniform Powder Compaction Without Heat

- What is the purpose of using a sealed laminated bag in CIP for battery components? Ensure Purity and High Density.

- What is hot isostatic pressing and cold isostatic pressing? Key Differences for Your Manufacturing Process

- What is the function of 300 MPa pressure in solid-state battery prep? Achieve Peak Densification and Ion Conductivity