The core principle of a colloidal mill is the use of high-speed mechanical force to generate intense hydraulic shear and turbulence. This action is achieved by passing a liquid or semi-solid material through a very narrow, precisely controlled gap between a rapidly spinning rotor and a stationary stator. The resulting forces break down, disperse, and homogenize particles or droplets within the fluid.

A colloidal mill is not a grinding machine that crushes particles through impact. Instead, it functions as a high-shear rotor-stator mixer, designed specifically to reduce droplet size in emulsions and de-agglomerate solid particles in liquid suspensions to create a stable, homogeneous final product.

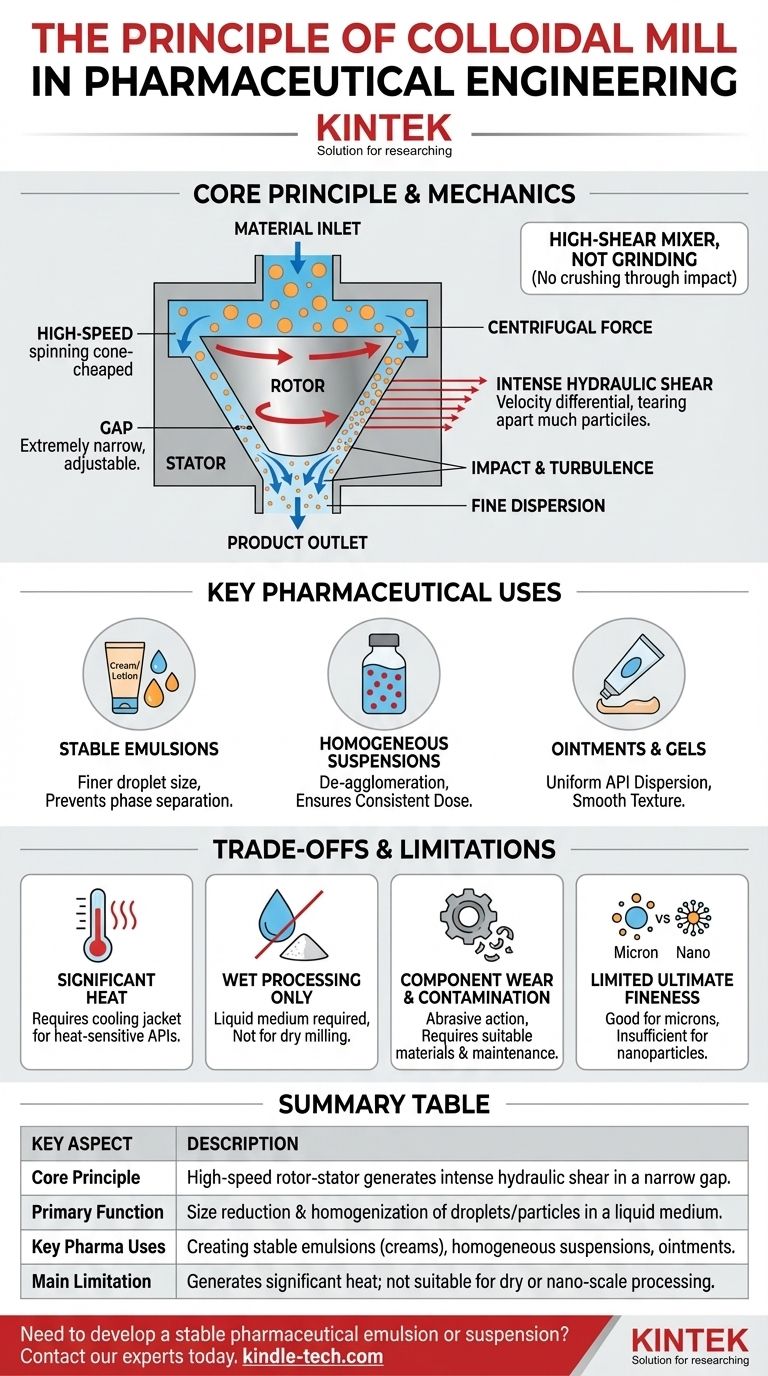

The Mechanics of High-Shear Action

To understand the principle, we must first look at the core components and the forces they generate. The entire process is designed to subject the material to extreme, localized energy.

The Rotor-Stator Design

The heart of the mill consists of a high-speed rotating component called the rotor, which spins inside a fixed component called the stator. Both parts are often cone-shaped and may be toothed, grooved, or textured.

The critical feature is the extremely small clearance, or gap, between the rotor and stator, which can be adjusted.

The Role of Centrifugal Force

Material is fed into the center of the rotor. As the rotor spins at very high speeds (typically 3,000 to 20,000 RPM), powerful centrifugal force throws the material outward towards the gap between the rotor and stator.

Intense Hydraulic Shear

As the material is forced into the narrow gap, it is subjected to a massive velocity differential. The layer of fluid in contact with the rotor is moving at high speed, while the layer in contact with the stator is stationary.

This differential creates intense hydraulic shear, which is the primary force responsible for size reduction. It acts like countless microscopic scissors, tearing apart droplets and breaking up clusters of solid particles.

Impact and Turbulence

In addition to shear, the material experiences high-frequency mechanical effects. As it exits the gap at high velocity, it collides with the surfaces of the stator and experiences extreme turbulence, further contributing to the dispersion and homogenization process.

Why This Principle Matters in Pharmaceuticals

The controlled application of high shear is essential for manufacturing many common pharmaceutical dosage forms. The goal is not just size reduction but also stability and consistency.

Creating Stable Emulsions

For products like creams, lotions, and sterile intravenous emulsions, the colloidal mill is used to break down oil and water droplets to a very fine size. This creates a high surface area and allows emulsifying agents to work effectively, preventing the mixture from separating over time.

Producing Homogeneous Suspensions

In liquid suspensions (e.g., oral antibiotics, antacids), the active drug is an insoluble solid. A colloidal mill ensures these solid particles are de-agglomerated and evenly distributed throughout the liquid, guaranteeing a consistent dose in every measure.

Manufacturing Ointments and Gels

The mill's homogenizing action is also used to ensure that active pharmaceutical ingredients (APIs) are finely and uniformly dispersed within a semi-solid base for ointments, creating a smooth texture and ensuring therapeutic efficacy.

Understanding the Trade-offs and Limitations

While powerful, the colloidal mill is not a universal solution. Its operating principle comes with specific constraints that are critical to consider.

Significant Heat Generation

The intense energy and friction involved in high-shear milling generate considerable heat. This can be detrimental to thermolabile (heat-sensitive) APIs or formulations. Most industrial colloidal mills incorporate a cooling jacket to mitigate this issue.

Not for Dry Milling

The principle of hydraulic shear fundamentally requires a liquid medium. Colloidal mills are exclusively used for wet processing and cannot be used to grind dry powders.

Component Wear and Contamination

For abrasive materials, the high-speed action can cause wear on the rotor and stator surfaces. This can be a source of metallic contamination and requires regular maintenance and material selection appropriate for pharmaceutical use (e.g., 316L stainless steel).

Limited Ultimate Fineness

While excellent for reducing particles to the low-micron range, a colloidal mill may not achieve the nanometer-scale particle sizes possible with technologies like high-pressure homogenizers or media mills.

How to Apply This to Your Formulation

Choosing the right processing method depends entirely on the physical characteristics and stability requirements of your final product.

- If your primary focus is creating a stable cream or lotion (emulsion): The colloidal mill is an excellent choice for reducing droplet size to prevent phase separation and achieve the desired texture.

- If your primary focus is ensuring uniform dosage in a liquid suspension: The mill's homogenizing action is ideal for de-agglomerating particles and guaranteeing even distribution of the API.

- If you are working with a highly heat-sensitive API: You must use a mill with an effective cooling jacket or consider lower-energy mixing methods if the heat generated cannot be controlled.

- If your goal is to create nanoparticles for enhanced bioavailability: A colloidal mill is likely insufficient; you should investigate high-pressure homogenization or nano-milling instead.

Understanding the principle of controlled hydraulic shear is the key to effectively leveraging the colloidal mill for robust, stable, and effective pharmaceutical formulations.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | High-speed rotor-stator generates intense hydraulic shear in a narrow gap. |

| Primary Function | Size reduction & homogenization of droplets/particles in a liquid medium (wet processing). |

| Key Pharmaceutical Uses | Creating stable emulsions (creams, lotions), homogeneous suspensions (oral antibiotics), ointments. |

| Main Limitation | Generates significant heat; not suitable for dry powders or nano-scale particle creation. |

Need to develop a stable pharmaceutical emulsion or suspension?

KINTEK specializes in precision lab equipment for pharmaceutical engineering. Our expertise can help you select the right colloidal mill or homogenization technology to ensure your formulations achieve the necessary stability, consistency, and dosage uniformity.

Contact our experts today to discuss your specific application and how we can support your R&D and production goals with reliable equipment and consumables.

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Jar Mill with Agate Grinding Jar and Balls

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

People Also Ask

- What is the primary function of the grinding process in LiCoO2/LSPS mixtures? Optimize Solid-State Battery Conductivity

- Why are excellent sealing and corrosion resistance required for WC-10Co ball milling? Ensure High-Purity Mixing Results

- What is the average speed of a ball mill? Optimize Grinding with Critical Speed Calculations

- What is the purpose of ball milling? A Versatile Tool for Material Synthesis and Modification

- What affects ball mill efficiency? Optimize Grinding Speed, Media, and Material for Peak Performance