In essence, vacuum thermoforming is a manufacturing process where a sheet of plastic is heated until it becomes pliable, draped over a mold, and then pulled tightly against the mold's surface by a vacuum. The plastic cools in this shape, creating a finished part. It is one of the simplest and most common methods for shaping plastic materials.

The core principle of vacuum forming is its simplicity and efficiency. By using heat to soften a plastic sheet and suction to shape it around a single mold, the process offers a fast and cost-effective solution for producing parts with simple geometries, especially at low to medium volumes.

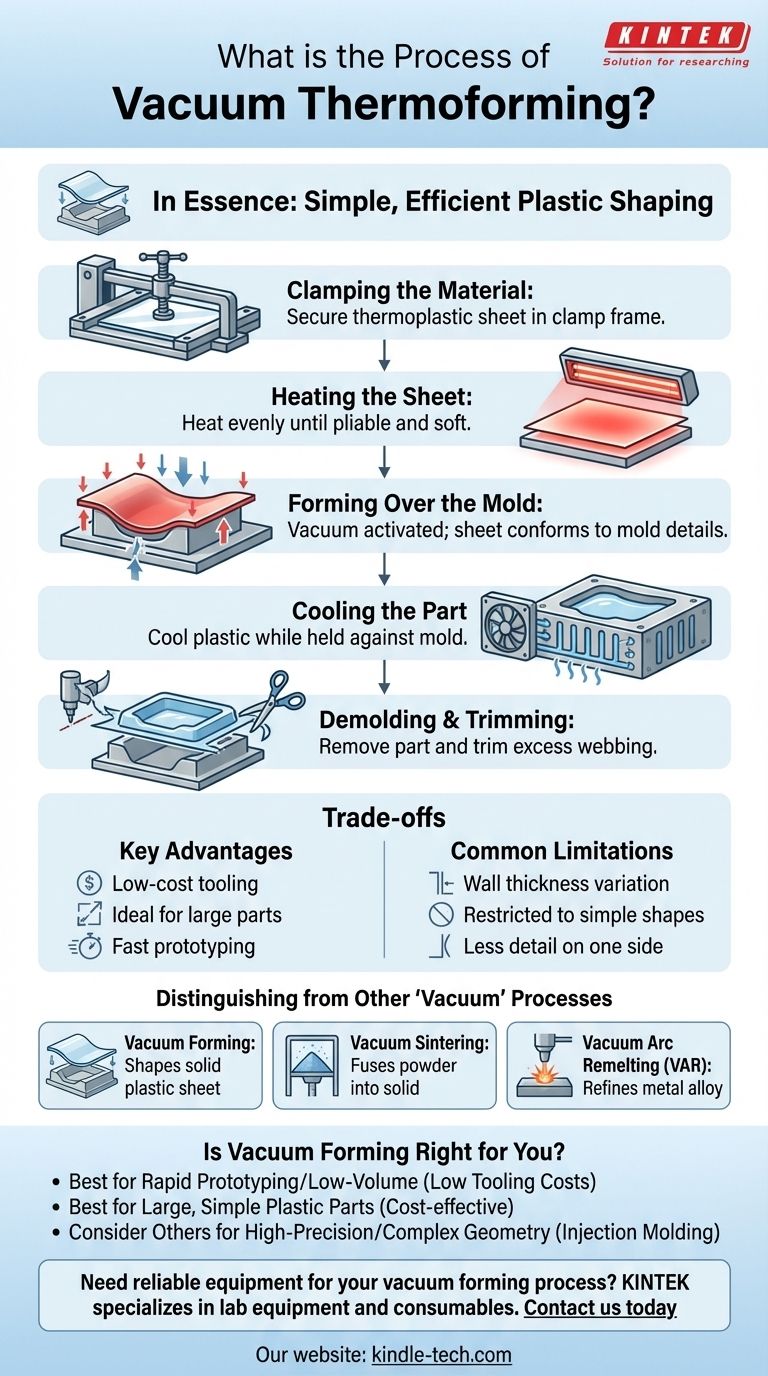

The Step-by-Step Vacuum Forming Process

To truly understand vacuum forming, it's best to break it down into its distinct stages. Each step is critical to achieving a well-formed and functional part.

1. Clamping the Material

First, a sheet of thermoplastic material is loaded into the machine and secured in a clamp frame. This frame holds the sheet in place during heating and forming.

2. Heating the Sheet

The clamped sheet is then moved to a heating station, typically under infrared heaters. The sheet is heated evenly until it reaches its specific forming temperature, at which point it becomes soft and pliable, almost like a rubber sheet.

3. Forming Over the Mold

Once pliable, the hot plastic sheet is positioned over a mold (also called a tool). The mold is raised into the sheet, and a vacuum is activated. The air pressure between the sheet and the mold is rapidly evacuated, causing atmospheric pressure to push the plastic down, forcing it to conform tightly to the mold's every detail.

4. Cooling the Part

The plastic must then cool while still held against the mold by the vacuum. Fans or sometimes liquid-cooling channels within the mold are used to accelerate this process and solidify the plastic in its new shape.

5. Demolding and Trimming

After cooling, the vacuum is released, and the formed part can be removed from the mold. The part will still be attached to the excess plastic from the original sheet, known as the "webbing." This excess material is then trimmed off using CNC routing, die-cutting, or manual methods to create the final product.

Understanding the Trade-offs

Like any manufacturing process, vacuum forming has clear advantages and limitations. Understanding these trade-offs is key to determining if it's the right choice for your application.

Key Advantages

The low cost of tooling is the primary advantage. Molds can be made from inexpensive materials like wood or epoxy for prototypes, or more durable aluminum for production, but they are significantly cheaper than the steel molds required for injection molding.

This process is also ideal for producing very large parts, such as automotive body panels, hot tub shells, or large equipment enclosures, which would be prohibitively expensive to produce with other methods.

Common Limitations

The most significant limitation is wall thickness variation. As the plastic sheet stretches over the mold, it becomes thinner, especially in deep corners and on vertical walls. This phenomenon, known as wall thinning, must be accounted for in the design.

Additionally, only the side of the part touching the mold receives fine detail. The other side will have a less defined, softer finish. The process is also generally restricted to simpler shapes and cannot produce complex features like undercuts without specialized tooling.

Distinguishing from Other "Vacuum" Processes

The term "vacuum" is used in many industrial processes, which can cause confusion. It is critical to differentiate vacuum forming from other unrelated manufacturing techniques.

Vacuum Forming vs. Vacuum Sintering

Vacuum forming shapes a solid plastic sheet. In contrast, vacuum sintering is a process used with metal or ceramic powders. The vacuum removes atmospheric gases from the powder before it is heated, allowing the particles to fuse together into a solid, dense object. These are fundamentally different processes for different materials.

Vacuum Forming vs. Vacuum Arc Remelting (VAR)

VAR is a metallurgical refining process. It uses a high-power electric arc in a vacuum to melt and purify a metal electrode, creating an ultra-clean, high-performance alloy ingot. It has no relation to shaping plastic sheets.

Is Vacuum Forming Right for Your Project?

Making the right choice depends entirely on your project's goals for cost, volume, and complexity.

- If your primary focus is rapid prototyping or low-volume production: Vacuum forming is an excellent choice due to its extremely low tooling costs and fast setup times.

- If your primary focus is creating large, simple plastic parts: This is one of the most cost-effective methods available for items like trays, enclosures, and covers.

- If your primary focus is high-precision parts with complex geometry: You should consider other processes, as injection molding will provide superior dimensional accuracy and the ability to create complex features.

Ultimately, vacuum forming is a powerful tool when its strengths align with your design intent.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Process | Heated plastic sheet is shaped over a mold using vacuum suction. |

| Best For | Low-cost tooling, large parts, low-to-medium volume production. |

| Main Limitation | Wall thickness variation (thinning) on deep draws. |

| Ideal Materials | Thermoplastics like ABS, PVC, PETG, Polycarbonate. |

Need reliable equipment for your vacuum forming process? KINTEK specializes in lab equipment and consumables, serving laboratory and manufacturing needs. Whether you're prototyping or scaling production, our solutions ensure precision and efficiency. Contact us today to discuss how we can support your project with the right tools and expertise!

Visual Guide

Related Products

- Touchscreen Automatic Vacuum Heat Press

- Double Plate Heating Press Mold for Lab

- Small Injection Molding Machine for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

People Also Ask

- What metal can withstand high temperatures? Choosing the Right Material for Extreme Heat

- What types of plastic can be used for pyrolysis? Transform Low-Value Waste into High-Value Resources

- How is thin film thickness measured? Achieve Atomic-Level Precision for Your Films

- What is the minimum coating thickness? How Steel Thickness Determines Your Galvanizing Needs

- What are the applications of compressors? Powering Industries from Manufacturing to HVAC

- What is the function of a laboratory drying oven for QPVA nanofiber membranes? Achieve Structural Stability with Precision

- What is the cheapest type of additive manufacturing process? Start 3D Printing on a Budget with FDM

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer