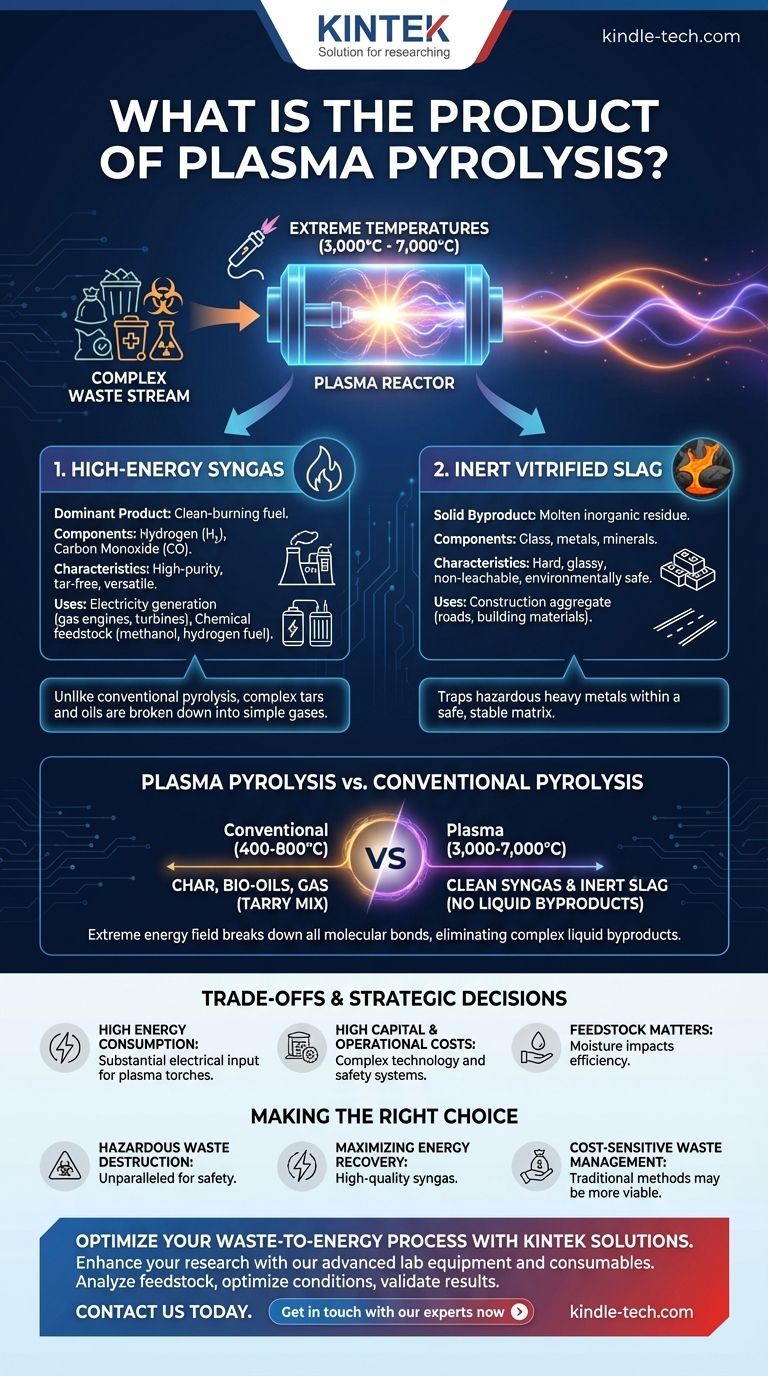

In short, plasma pyrolysis primarily produces a high-energy synthesis gas (syngas) and an inert, vitrified slag. Unlike conventional pyrolysis, which creates a mix of char, oils, and gas, the extreme temperatures of a plasma process fundamentally alter the outputs. It breaks down waste into its most basic molecular components, resulting in cleaner and more industrially useful products.

The true value of plasma pyrolysis isn't just in its product slate, but in its ability to achieve near-total material destruction. It converts complex, often hazardous, waste into a clean, hydrogen-rich fuel gas and a non-toxic, usable solid residue.

What Makes Plasma Pyrolysis Different?

While standard pyrolysis uses external heat to decompose material in an oxygen-starved environment, plasma pyrolysis takes this concept to an extreme. Understanding this distinction is key to understanding its unique products.

The Role of Extreme Temperature

Plasma pyrolysis utilizes a plasma torch to generate temperatures ranging from 3,000°C to over 7,000°C. This is significantly hotter than conventional pyrolysis, which typically operates between 400°C and 800°C.

This intense energy field doesn't just "cook" the material; it completely breaks the chemical bonds of the feedstock molecules.

Complete Molecular Dissociation

The plasma environment forces organic materials to dissociate into their constituent atoms. Complex hydrocarbons, plastics, and other compounds are broken down into simple elemental gases.

Inorganic materials like glass, metals, and minerals are melted down into a molten lava-like substance.

A Closer Look at the Primary Products

The unique conditions of plasma pyrolysis lead to two main outputs with very different properties and uses compared to traditional methods.

The Main Product: High-Quality Syngas

The dominant product is syngas, or synthesis gas. This is a clean-burning fuel gas composed almost entirely of hydrogen (H2) and carbon monoxide (CO).

Because the high temperatures crack the complex, tarry molecules found in conventional pyrolysis gas, the resulting syngas is purer and more versatile. It can be used directly in gas engines or turbines to generate electricity, or it can serve as a chemical building block to produce hydrogen, methanol, and other valuable liquid fuels.

The Solid Byproduct: Vitrified Slag

The inorganic portion of the waste stream melts and then cools into a hard, glassy, and inert solid known as vitrified slag.

This process is a major advantage for waste treatment. The vitrification traps heavy metals and other hazardous components within the glassy matrix, rendering them non-leachable and environmentally safe. This slag is often used as a construction aggregate for roads or building materials.

The Lack of Liquid Products

A key differentiator of plasma pyrolysis is the near-total absence of liquid byproducts like tars, bio-oils, or wood vinegars.

The extreme temperatures ensure these long-chain hydrocarbons cannot survive the process; they are immediately broken down into the simpler components of syngas. This simplifies plant operations, as handling and processing corrosive and complex tars is a significant challenge in conventional pyrolysis.

Understanding the Trade-offs

While powerful, plasma pyrolysis is not a universal solution. Its benefits must be weighed against its significant operational demands.

High Energy Consumption

Creating and sustaining a plasma field is extremely energy-intensive. While the syngas produced can be used to generate electricity and make the plant energy-positive, the initial electrical input required to run the plasma torches is substantial.

High Capital and Operational Costs

Plasma gasification plants are complex and expensive to build and maintain. The high-tech components, particularly the plasma torches, and the need for robust safety systems contribute to higher capital expenditures compared to incineration or standard pyrolysis.

Feedstock Requirements

While plasma pyrolysis is highly flexible and can process nearly any type of waste (including medical and hazardous waste), the composition of the feedstock still matters. High moisture content, for example, requires more energy to overcome, impacting the overall efficiency of the system.

Making the Right Choice for Your Goal

Selecting a waste-to-energy technology depends entirely on your primary objective.

- If your primary focus is hazardous waste destruction: Plasma pyrolysis offers unparalleled effectiveness, converting dangerous materials into a safe, non-leachable slag.

- If your primary focus is maximizing energy recovery: The high-quality, hydrogen-rich syngas is a more versatile and valuable energy carrier than the mixed outputs of traditional pyrolysis.

- If your primary focus is cost-sensitive waste management: The high capital and energy costs may make traditional methods like incineration or anaerobic digestion more financially viable for simple municipal solid waste.

Ultimately, choosing plasma pyrolysis is a strategic decision that prioritizes complete waste elimination and high-value energy recovery over lower initial investment.

Summary Table:

| Product Type | Main Components | Key Characteristics | Primary Uses |

|---|---|---|---|

| Syngas | Hydrogen (H₂), Carbon Monoxide (CO) | High-purity, tar-free, clean-burning fuel | Electricity generation, chemical feedstock for fuels |

| Vitrified Slag | Molten inorganic materials (glass, metals) | Inert, non-leachable, glass-like solid | Construction aggregate, safe disposal |

| Liquid Byproducts | None (or minimal) | Absence of tars and oils due to extreme temperatures | Simplifies processing and handling |

Optimize Your Waste-to-Energy Process with KINTEK Solutions

Are you looking to maximize energy recovery from complex or hazardous waste streams? The superior syngas and safe slag produced by plasma pyrolysis can transform your waste management strategy.

At KINTEK, we specialize in advanced laboratory equipment and consumables that support the research and development of cutting-edge thermal processes like plasma pyrolysis. Whether you're in the pilot phase or scaling up, our precision tools can help you analyze feedstock, optimize conditions, and validate your results.

Contact us today to discuss how our solutions can enhance your pyrolysis research and help you achieve cleaner, more efficient waste conversion. Let's turn your challenging waste streams into valuable resources.

Get in touch with our experts now

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- Wall Mounted Water Distillation Unit

- Customizable CO2 Reduction Flow Cell for NRR ORR and CO2RR Research

- Laboratory High Throughput Tissue Grinding Mill Grinder

People Also Ask

- What are the disadvantages of plasma enhanced chemical vapor deposition? Managing the Trade-offs of Low-Temperature Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the drawbacks of PECVD? Understanding the Trade-offs of Low-Temperature Deposition