The product size achieved by a hammer mill is not a single fixed value but a controlled outcome of its configuration. The primary factors determining the final particle size are the screen installed in the mill and the speed of the rotating hammers, allowing it to grind materials to a powder, often under 1mm.

The key to understanding a hammer mill's output is to see it not as a machine with one product size, but as a system you can configure. The final particle size is a direct result of the choices you make, primarily the screen size which acts as a physical gate for the material.

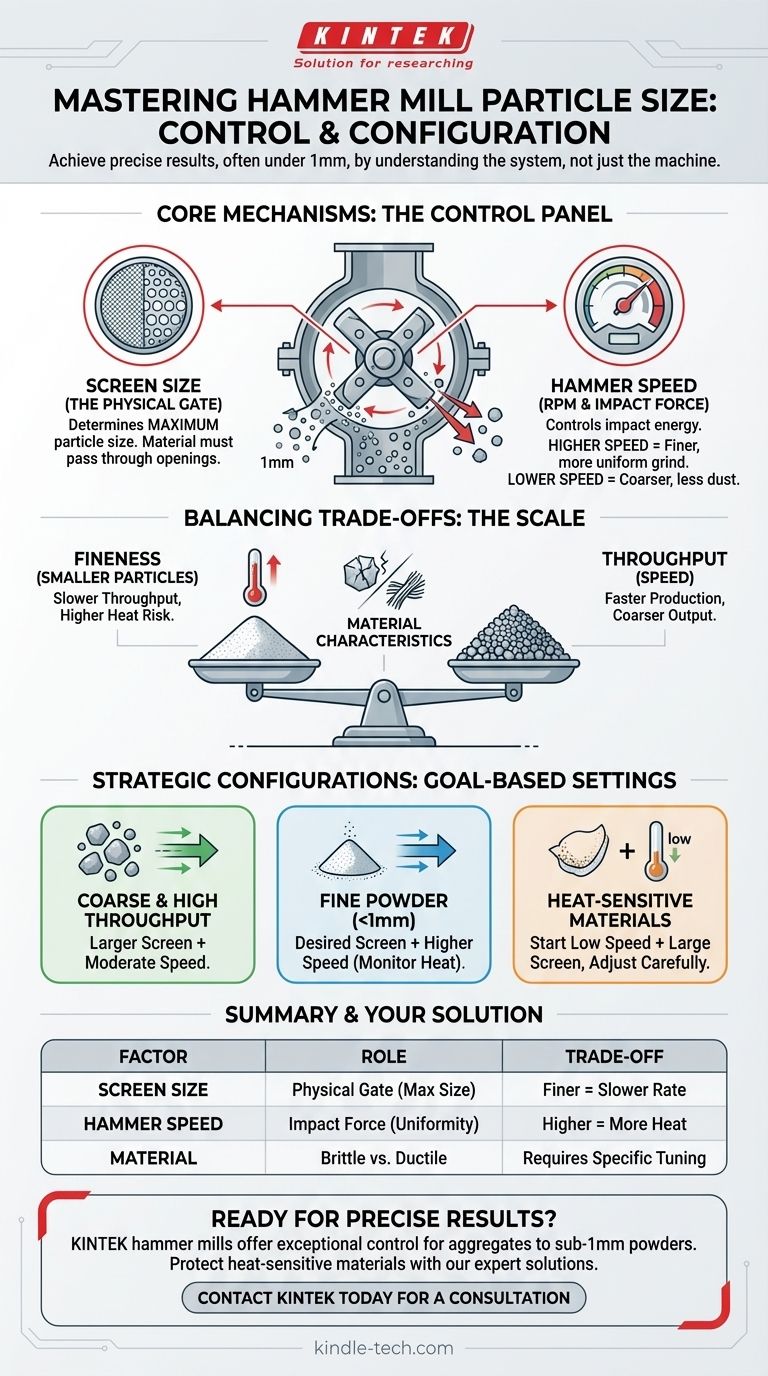

The Core Mechanisms Controlling Particle Size

A hammer mill reduces material size through repeated, high-velocity impacts. Understanding the two main components that control this process is essential for achieving your desired outcome.

The Role of the Screen

The screen is the most critical component for determining the maximum product size. It is a perforated metal sheet that lines the grinding chamber.

Material is shattered by the hammers and remains in the chamber until it is small enough to pass through the screen's openings. This makes the screen a physical classifier.

Therefore, if you install a screen with 1mm openings, the final product will consist of particles no larger than 1mm.

The Influence of Hammer Speed

The speed of the rotor, often measured in RPM (revolutions per minute), is the second key factor. It dictates the force and frequency of the impacts.

A higher hammer speed results in more energetic collisions. This shatters the material more effectively and creates a finer grind with a tighter particle size distribution, even with the same screen.

A lower hammer speed results in less forceful impacts. This is often used for coarser products or with brittle materials that break apart easily, and it helps reduce the creation of unwanted ultra-fine dust.

Understanding the Trade-offs

Adjusting the hammer mill to achieve a specific particle size involves balancing competing factors. There is no single "best" setting; there is only the best setting for your specific goal.

Fineness vs. Throughput

There is a direct trade-off between how fine your product is and how quickly you can produce it.

Using a smaller screen opening to create a very fine powder will lower the mill's throughput. The material must remain in the chamber longer to be sufficiently reduced, slowing the overall process.

Heat Generation

Higher rotor speeds and longer grinding times (from using fine screens) generate significant heat through friction and impact energy.

This can be a major issue for heat-sensitive materials, such as certain plastics, chemicals, or food products, which may melt, degrade, or change their chemical properties.

Material Characteristics

The properties of your feed material dictate how it will behave in the mill.

Brittle materials shatter easily and may require lower hammer speeds to avoid producing an excess of fine dust. Ductile or fibrous materials are more difficult to grind and may require higher speeds and specialized hammer designs to be processed effectively.

Making the Right Choice for Your Goal

To achieve the desired product size, you must configure the mill based on the properties of your material and your production priorities.

- If your primary focus is high throughput for a coarse product: Use a larger screen opening and a moderate hammer speed.

- If your primary focus is producing a fine powder (e.g., under 1mm): Use a screen with the desired opening size and increase the hammer speed, while monitoring for heat generation.

- If you are processing a heat-sensitive material: Start with a lower hammer speed and a larger screen, gradually adjusting to find a balance that achieves the necessary size reduction without causing thermal damage.

Ultimately, controlling a hammer mill is about balancing these variables to match your specific material and processing needs.

Summary Table:

| Factor | Role in Particle Size Control |

|---|---|

| Screen Size | Acts as a physical gate; determines the maximum particle size (e.g., 1mm screen = sub-1mm product). |

| Hammer Speed (RPM) | Controls impact force; higher speed creates a finer, more uniform grind. |

| Material Type | Brittle materials shatter easily; ductile/fibrous materials require more energy. |

| Trade-off | Finer grinds = lower throughput & higher heat generation. |

Ready to achieve your precise particle size goals?

KINTEK's hammer mills are engineered for exceptional control and reliability, allowing you to fine-tune screen size and rotor speed for perfect results—from coarse aggregates to fine powders under 1mm. Whether you're processing brittle chemicals or tough polymers, our expertise ensures optimal efficiency and protects heat-sensitive materials.

Let's configure the ideal solution for your lab's needs. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

- Laboratory Jar Mill with Agate Grinding Jar and Balls

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

People Also Ask

- How do stainless steel grinding jars and balls contribute to mechanical alloying? Optimize HEA Powder Synthesis

- Why are silicon nitride or zirconia preferred for milling iodo-vanadate-lead precursors? Ensure High Purity Results

- Why are zirconia (ZrO2) milling jars recommended for sulfide electrolytes? Ensure Purity in Li6PS5Cl Synthesis

- Why use zirconia ball milling jars for SiC/ZTA composite powders? Ensure High Purity & Efficient Particle Refinement

- What is the benefit of using tungsten carbide (WC) milling jars and balls? Achieve High-Energy Milling Efficiency