In essence, the purpose of an Indium Tin Oxide (ITO) coating is to provide a surface that is both electrically conductive and almost perfectly transparent to visible light. This rare combination of properties makes it a critical, enabling material for a vast range of modern electronic devices where we need to pass electricity across a clear surface.

While seemingly simple, the dual-nature of ITO solves a fundamental engineering challenge: how to integrate electrical function with optical clarity. Understanding this balance is key to grasping why it's the foundation for technologies like touchscreens, flat-panel displays, and solar cells.

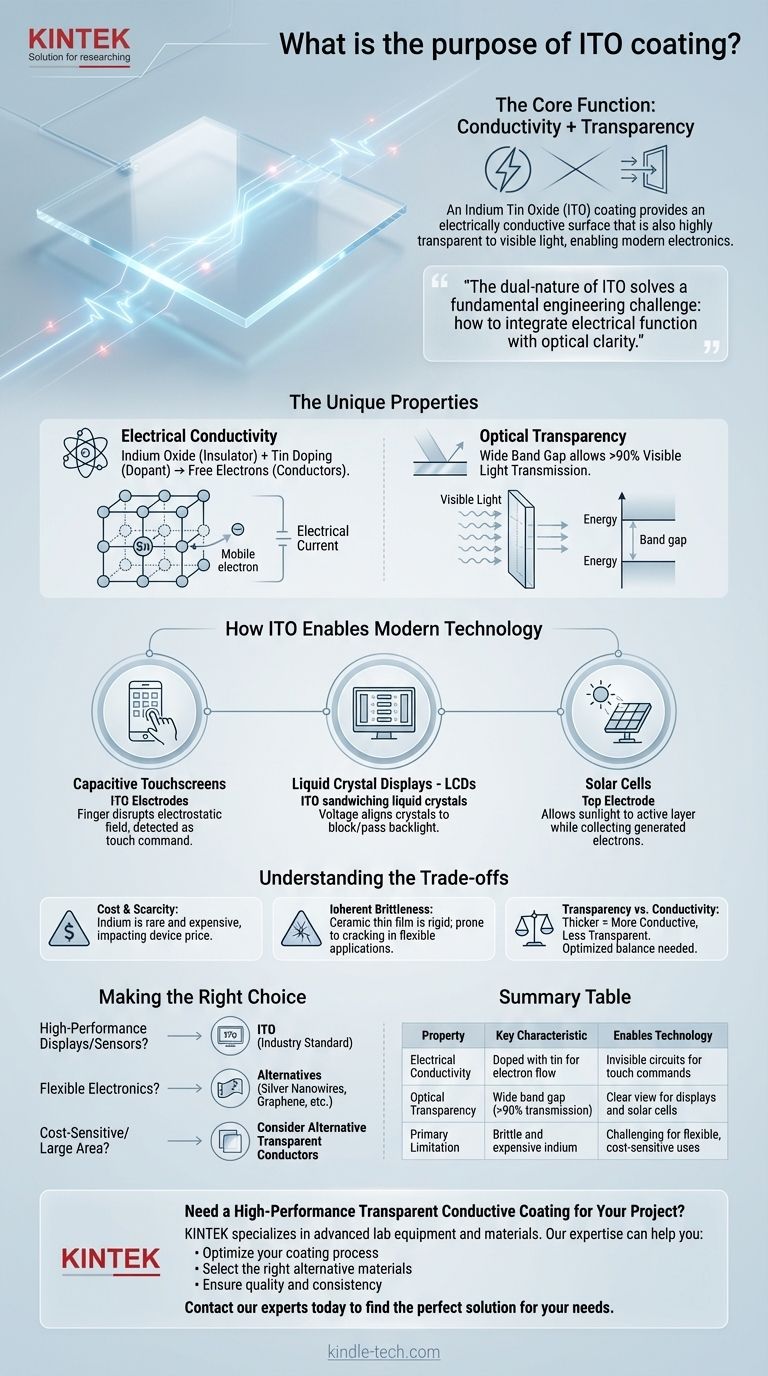

The Unique Properties of ITO

Indium Tin Oxide's utility comes from two primary characteristics that are typically mutually exclusive in most materials. It achieves this through a carefully engineered material structure.

Electrical Conductivity

ITO starts as Indium Oxide, which is an electrical insulator. By doping it with a small amount of tin during manufacturing, free electrons are introduced into the material's crystal lattice.

These free electrons are not tightly bound to any single atom, allowing them to move freely when a voltage is applied. This movement of electrons is what we call an electrical current.

Optical Transparency

Despite being conductive, ITO remains highly transparent (often over 90%) to visible light. This is because the material has a wide "band gap."

In simple terms, photons of visible light do not have enough energy to be absorbed by the electrons in the ITO. Lacking the energy to interact, the light simply passes through unimpeded, making the coating appear clear to the human eye.

How ITO Enables Modern Technology

The ability to create transparent circuits is not just a novelty; it is the core principle behind many devices we use daily. The ITO layer acts as an invisible electrode.

Capacitive Touchscreens

The screen on your smartphone or tablet has a grid of ITO electrodes. This grid maintains a stable electrostatic field.

When your conductive finger touches the screen, it disrupts this field at a specific point. The device's controller instantly detects this change in capacitance and registers it as a touch command.

Liquid Crystal Displays (LCDs)

In an LCD, a layer of liquid crystals is sandwiched between two transparent ITO electrodes.

By applying a precise voltage to specific parts of the ITO grid, an electric field is created that causes the liquid crystals to align in a particular way. This alignment either blocks or allows light from the backlight to pass through, forming the images you see.

Solar Cells

For a solar cell to be efficient, sunlight must reach the active photovoltaic material where it gets converted into electricity.

An ITO coating serves as the perfect top electrode. It allows sunlight to pass through to the active layer while simultaneously providing a conductive path to collect the electrons generated by the light.

Understanding the Trade-offs

While incredibly useful, ITO is not a perfect material. Engineers must contend with significant limitations that drive ongoing research into alternatives.

Cost and Scarcity

The "I" in ITO stands for Indium, a rare and expensive element. Its limited global supply and high demand make ITO a costly component, significantly impacting the final price of devices.

Inherent Brittleness

ITO is a ceramic material. As a thin film, it is rigid and brittle. When applied to a flexible plastic substrate, it is prone to cracking and failing after repeated bending or flexing.

This brittleness is the single biggest obstacle to creating truly durable and long-lasting flexible electronics, such as foldable phones or wearable displays.

The Transparency vs. Conductivity Balance

There is a direct trade-off between the coating's electrical resistance and its transparency.

A thicker coating is more conductive (less resistive) but also less transparent. Conversely, a thinner, more transparent coating is more resistive. Engineers must carefully optimize this balance for the specific needs of each application.

Making the Right Choice for Your Application

Choosing the right transparent conductive film requires balancing performance, cost, and physical requirements.

- If your primary focus is high-performance displays or sensors: ITO remains the industry standard due to its unmatched, well-understood balance of high transparency and low electrical resistance.

- If your primary focus is flexible electronics: You must account for ITO's brittleness and strongly consider alternatives like silver nanowires, conductive polymers, or graphene, even if they involve other trade-offs.

- If your primary focus is cost-sensitive or large-area applications: The high cost of indium may make alternative transparent conductors a more viable choice, provided their performance meets your minimum requirements.

Ultimately, selecting the right material depends on a clear understanding of the specific demands and constraints of your project.

Summary Table:

| Property | Key Characteristic | Enables Technology |

|---|---|---|

| Electrical Conductivity | Doped with tin to allow electron flow | Creates invisible circuits for touch commands |

| Optical Transparency | Wide band gap allows >90% light transmission | Provides clear view for displays and solar cells |

| Primary Limitation | Brittle and contains expensive indium | Challenging for flexible, cost-sensitive applications |

Need a High-Performance Transparent Conductive Coating for Your Project?

Choosing the right material is critical for the success of your electronic device. Whether you're developing a new display, a sensitive touch sensor, or a flexible wearable, the balance between conductivity, transparency, and durability is paramount.

KINTEK specializes in advanced lab equipment and materials, including solutions for thin-film deposition and coating analysis. Our expertise can help you:

- Optimize your coating process for maximum performance and yield.

- Select the right alternative materials if ITO's limitations are a concern for your application.

- Ensure quality and consistency in your R&D or production line.

Let's discuss how we can support your laboratory's innovation in transparent electronics. Contact our experts today to find the perfect solution for your needs.

Visual Guide

Related Products

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Platinum Auxiliary Electrode for Laboratory Use

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

People Also Ask

- What are the advantages disadvantages and uses of sheet metal? The Ultimate Guide to Material Selection

- Why is platinum unreactive? The Atomic Secrets Behind Its Remarkable Stability

- What is titanium used for in manufacturing? Leveraging High-Performance Properties for Critical Applications

- What are the disadvantages of using metal? Understanding Corrosion, Weight, and Cost Challenges

- How does hardness change with temperature? Understand the Inverse Relationship to Prevent Failure