The primary purpose of using a calibrated shrinkage product is to provide a physical, integrated measurement of the work done inside a furnace. It allows an operator to accurately monitor and verify the consistency and repeatability of a firing cycle by measuring the total effect of temperature over time, not just the peak air temperature at a single point.

A calibrated shrinkage product is not a thermometer. It is a process control tool that measures the cumulative heat work—the combined effect of temperature and time—to ensure every batch you fire receives the exact same thermal treatment.

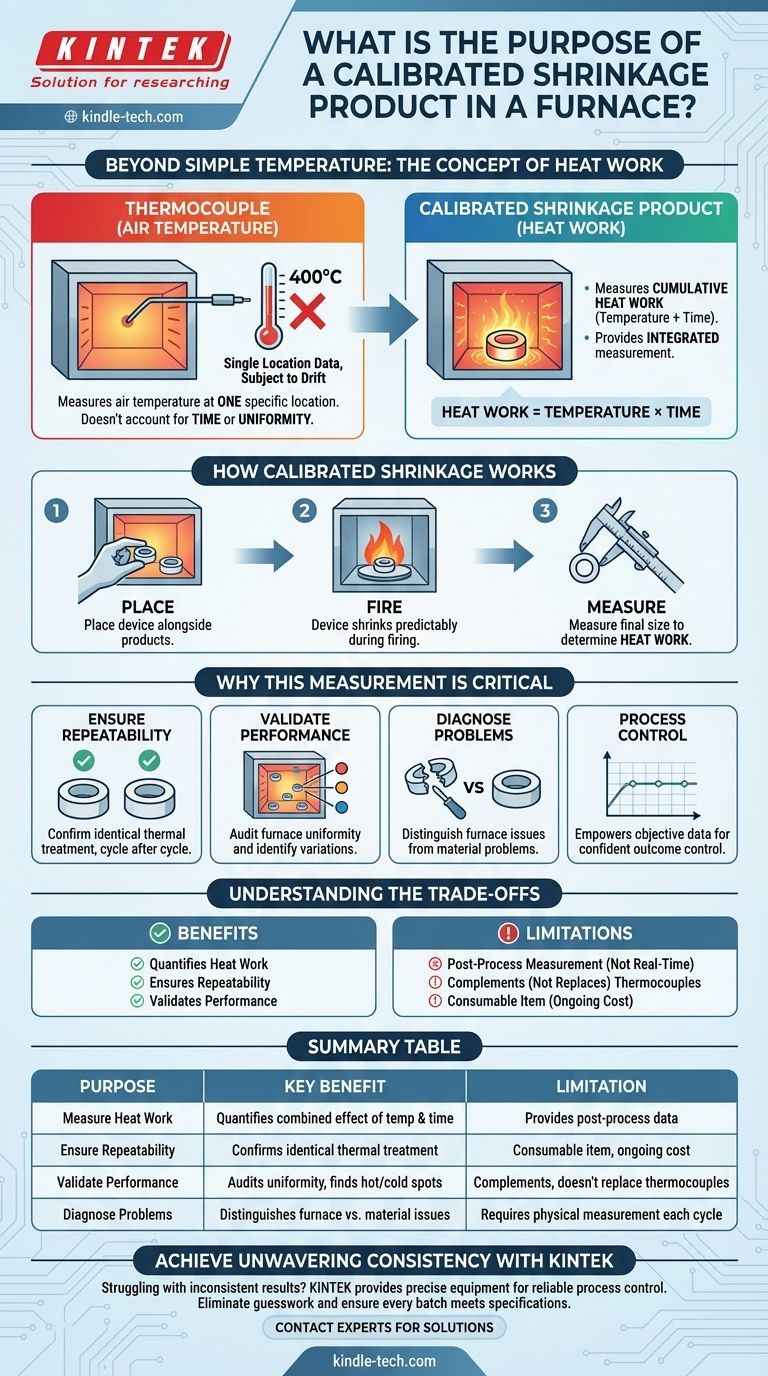

Beyond Simple Temperature: The Concept of Heat Work

To understand the value of a calibrated shrinkage product, you must first recognize the limitations of standard furnace controls.

The Limitation of Thermocouples

A thermocouple is a crucial sensor, but it only measures the air temperature at one specific location inside the furnace.

This single data point doesn't always represent the actual temperature your product experiences, especially in large furnaces with potential hot or cold spots.

Furthermore, a thermocouple reading can drift over time, leading to process inconsistencies that are difficult to diagnose.

What is "Heat Work"?

Heat work is the total amount of thermal energy transferred to a product throughout a firing cycle. It's a function of both temperature and the duration spent at that temperature.

Two different firing cycles—one with a higher peak temperature for a shorter time, and another with a lower peak temperature for a longer time—can result in the exact same amount of heat work and produce identical results.

How Calibrated Shrinkage Works

A calibrated shrinkage product is a precisely manufactured ceramic item designed to shrink by a predictable amount when exposed to a specific quantity of heat work.

You place it in the furnace alongside your actual products. After the firing, you measure its final size.

This measurement corresponds to a known amount of heat work, giving you a definitive, physical record of the conditions inside the furnace, independent of the thermocouple's reading.

Why This Measurement is Critical

Integrating this tool into your process moves you from simply controlling temperature to truly controlling outcomes.

Ensuring Process Repeatability

The most critical goal in any thermal process is repeatability. You need to ensure the product made today is identical to the one made six months from now.

By providing a consistent benchmark for heat work, these devices confirm that your furnace is performing the same way, cycle after cycle, even if the controller's sensors have slightly drifted.

Validating Your Furnace Performance

A calibrated shrinkage product acts as an independent auditor of your furnace's performance.

You can use multiple devices placed in different locations to map your furnace's temperature uniformity, identifying hot and cold spots that could affect product quality. This is essential for process validation and qualification.

Diagnosing Furnace Problems

If your products start failing quality control, a calibrated shrinkage device provides immediate insight.

A deviation in the expected shrinkage tells you instantly whether the problem is with the furnace's thermal performance or with the raw materials themselves, saving significant time in troubleshooting.

Understanding the Trade-offs

While incredibly valuable, these devices are a specific tool with inherent limitations that you must understand.

It's a Post-Process Measurement

Unlike a thermocouple which provides real-time data, a shrinkage product gives you a result only after the firing cycle is complete.

It is a verification tool for process control, not a real-time feedback mechanism for the furnace controller.

It Complements, Not Replaces, Thermocouples

You still need thermocouples and a controller to run the furnace. A shrinkage device is a secondary measurement system.

The thermocouple controls the furnace's operation, while the calibrated shrinkage product validates that the operation produced the desired result. They work together to create a robust and reliable system.

It Is a Consumable Item

Because each device can only be used once, it represents an ongoing operational cost.

However, this cost is typically negligible compared to the cost of scrapped products, failed batches, or lengthy troubleshooting caused by an unverified firing process.

How to Apply This to Your Process

Your specific goal will determine how you can best leverage this tool.

- If your primary focus is quality control and repeatability: Use one device in the same location for every firing cycle to build a statistical process control (SPC) chart and monitor for any drift.

- If your primary focus is new process development: Use multiple devices to determine the exact heat work required to achieve desired product properties, making the process easily transferable to other furnaces.

- If your primary focus is troubleshooting a furnace: Place devices throughout the furnace chamber to map temperature uniformity and quickly identify performance issues like failing heating elements or poor circulation.

Ultimately, using a calibrated shrinkage product empowers you with objective data to control the outcome of your thermal process with confidence.

Summary Table:

| Purpose | Key Benefit | Limitation |

|---|---|---|

| Measure Heat Work | Quantifies the combined effect of temperature & time | Provides post-process data, not real-time feedback |

| Ensure Repeatability | Confirms identical thermal treatment cycle after cycle | Is a consumable item, representing an ongoing cost |

| Validate Performance | Audits furnace uniformity and identifies hot/cold spots | Complements, but does not replace, thermocouples |

| Diagnose Problems | Distinguishes furnace issues from material problems | Requires physical measurement after each firing cycle |

Achieve Unwavering Consistency in Your Thermal Processes with KINTEK

Are you struggling with inconsistent firing results or spending too much time troubleshooting your furnace? A calibrated shrinkage product is the definitive tool for measuring the true heat work your materials receive, moving you beyond unreliable temperature readings alone.

At KINTEK, we specialize in providing laboratories with the precise equipment and consumables needed for reliable process control. Our solutions help you eliminate guesswork, reduce scrap, and ensure every batch meets your exact specifications.

Ready to take control of your heat treatment outcomes?

Contact our experts today to find the right calibrated shrinkage solution for your specific furnace and application. Let KINTEK be your partner in achieving perfect repeatability.

Visual Guide

Related Products

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Automatic Laboratory Heat Press Machine

People Also Ask

- How can different materials have different heat capacity? Unlocking the Microscopic Secrets of Energy Storage

- What is the most common industrial ceramic? Discover Why Alumina Dominates Countless Applications

- What is the maximum temperature for alumina tube? Unlock Its Full Potential with High Purity

- What material is used for furnace insulation? Key Materials for Maximum Efficiency & Performance

- What are the factors that affect heat transfer? Master the Key Variables for Optimal Thermal Performance