In any thermal system, the rate of heat transfer is fundamentally governed by three core factors: the temperature difference between two points, the geometric and material properties of the media involved, and the surface area available for the exchange. The specific way these factors interact depends entirely on which of the three modes of heat transfer—conduction, convection, or radiation—is dominant.

The key to controlling heat transfer is recognizing that it isn't a passive phenomenon. It's a dynamic process that can be actively managed by manipulating specific variables like material selection, surface characteristics, and fluid flow to achieve a desired outcome, whether that's rapid cooling or effective insulation.

The Three Modes of Heat Transfer

Heat always moves from a hotter object to a colder one. The rate at which it moves, however, is dictated by the pathway it takes. The factors that influence this rate are best understood by examining each of the three distinct modes of transfer.

Factors Influencing Conduction

Conduction is the transfer of heat through direct molecular collision, primarily within solid materials or between objects in direct contact. Think of the handle of a metal pan heating up on a stove.

Temperature Difference (ΔT)

The primary driver of conduction is the temperature gradient. A larger temperature difference between the hot and cold sides of an object results in a significantly faster rate of heat transfer.

Material Property: Thermal Conductivity (k)

Every material has an intrinsic ability to conduct heat, known as thermal conductivity (k). Materials with high 'k' values, like copper and aluminum, transfer heat quickly and are called conductors. Materials with low 'k' values, like wood, plastic, and fiberglass, transfer heat slowly and are known as insulators.

Cross-Sectional Area (A)

The area through which heat can travel directly impacts the transfer rate. A pipe with a larger diameter or a wall with a larger surface area will transfer more total heat than a smaller one, assuming all other factors are equal.

Path Length or Thickness (L)

The distance the heat must travel affects the rate of transfer. A thicker wall will slow down conduction, while a thinner one will allow heat to pass through more readily. This is why insulation is thick.

Factors Influencing Convection

Convection is the transfer of heat through the bulk movement of fluids (liquids or gases). It's the process that drives weather patterns and cools your computer's CPU with a fan.

Fluid Velocity

Convection can be natural (driven by buoyancy, as hot air rises) or forced (driven by a fan or pump). Increasing the velocity of the fluid, especially in forced convection, dramatically increases the heat transfer rate by constantly replacing cooler fluid at the surface.

Surface Area (A)

Just as with conduction, a larger surface area exposed to the moving fluid allows for a greater rate of heat exchange. This is the principle behind heat sinks, which use fins to maximize their surface area.

Fluid Properties

The specific heat, viscosity, density, and thermal conductivity of the fluid itself play a significant role. For example, water is much more effective at transferring heat via convection than air.

Temperature Difference (ΔT)

The rate of convective heat transfer is directly proportional to the temperature difference between the surface and the moving fluid.

Factors Influencing Radiation

Radiation is the transfer of heat via electromagnetic waves (specifically infrared) and requires no medium—it can even occur through a vacuum. It's how the sun heats the Earth and how you feel warmth from a distant fire.

Surface Temperature

The rate of radiative heat transfer is extremely sensitive to temperature. It is proportional to the absolute temperature raised to the fourth power (T⁴). This means that doubling the absolute temperature of an object increases its radiative heat output by a factor of sixteen.

Surface Emissivity (ε)

Emissivity is a measure of a material's ability to radiate thermal energy, with a value between 0 and 1. A perfect black body has an emissivity of 1. Dull, black surfaces have high emissivity and are excellent radiators, while shiny, reflective surfaces have low emissivity.

Surface Area and View Factor

The total surface area of the emitting object determines how much energy it can radiate. The "view factor" describes the geometric relationship between the emitting and receiving surfaces—essentially, how much of the radiating object the absorbing object can "see."

Understanding the Trade-offs

Manipulating these factors to control heat transfer always involves balancing competing priorities. Understanding these trade-offs is critical for any practical application.

Cost vs. Performance

High-performance materials, like copper for conduction or specialized thermal fluids for convection, are often significantly more expensive than their less effective counterparts, such as aluminum or air.

Structural Integrity vs. Thermal Design

Improving conduction by making a material thinner can compromise its mechanical strength. Similarly, designing for optimal airflow (convection) might lead to a less robust or aesthetically pleasing structure.

Efficiency vs. Energy Consumption

Forced convection is highly effective, but running pumps and fans consumes energy, generates noise, and adds a point of mechanical failure. The benefit of increased heat transfer must be weighed against these operational costs.

Making the Right Choice for Your Goal

Your strategy for managing heat transfer depends entirely on your objective. Use the factors discussed as levers to achieve your specific thermal goal.

- If your primary focus is rapid cooling (e.g., a high-power CPU): Prioritize forced convection with a high-velocity fan, use a high-conductivity material like copper for the heat spreader, and maximize surface area with a finned heat sink.

- If your primary focus is insulation (e.g., a well-insulated home): Use materials with very low thermal conductivity (like fiberglass or foam), make them as thick as is practical, and trap air to prevent convection from occurring.

- If your primary focus is managing extreme heat (e.g., a furnace or spacecraft re-entry): You must account for radiation. Use materials with low emissivity (highly reflective surfaces) to block radiative heat transfer and high-emissivity surfaces to radiate unwanted heat away into a cooler environment.

By mastering these fundamental factors, you gain direct control over the thermal performance of any system you design or analyze.

Summary Table:

| Mode of Heat Transfer | Key Influencing Factors |

|---|---|

| Conduction | Temperature Difference (ΔT), Thermal Conductivity (k), Cross-Sectional Area (A), Thickness (L) |

| Convection | Fluid Velocity, Surface Area (A), Fluid Properties, Temperature Difference (ΔT) |

| Radiation | Surface Temperature (T⁴), Surface Emissivity (ε), Surface Area & View Factor |

Need to Optimize Heat Transfer in Your Lab Processes?

Whether you require rapid cooling for sensitive reactions or robust insulation for high-temperature furnaces, understanding these factors is the first step. KINTEK specializes in providing the right lab equipment and consumables—from high-conductivity materials to advanced thermal management systems—to help you achieve precise and efficient thermal control.

Contact our thermal experts today to discuss how we can support your specific laboratory needs and enhance your system's performance.

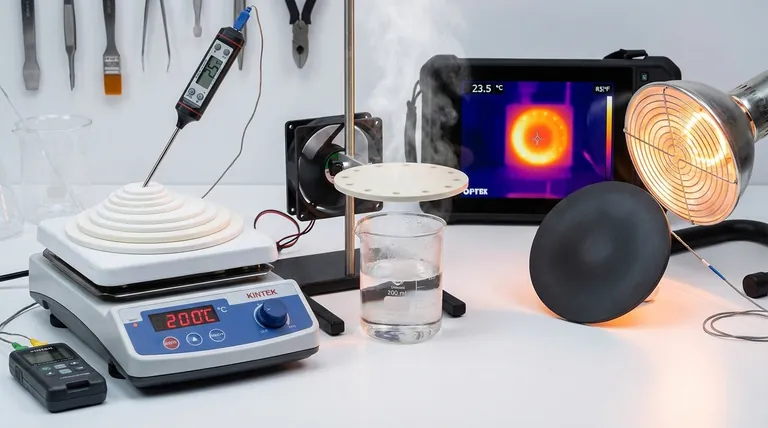

Visual Guide

Related Products

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

- Carbon Graphite Plate Manufactured by Isostatic Pressing Method

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- What is the most common industrial ceramic? Discover Why Alumina Dominates Countless Applications

- What is refractory ceramic? The Engineered Barrier for Extreme Heat and Harsh Environments

- What are some ways you can prevent injury when dealing with hot substances and objects? A Proactive Framework for Thermal Safety

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- What is the maximum temperature for alumina tube? Unlock Its Full Potential with High Purity