At its core, furnace insulation is not one specific material but a family of specialized ceramics and metals chosen for their ability to withstand extreme heat. The most common materials include ceramic fibers like alumina and zirconia, graphite, and refractory metals such as molybdenum and tungsten, with the final choice depending entirely on the furnace's operating temperature and internal atmosphere.

The selection of a furnace insulation material is a critical engineering decision that directly impacts energy efficiency, temperature stability, and equipment longevity. The key is to match the material's properties—its heat resistance and chemical stability—to the specific demands of the furnace's environment, primarily its maximum temperature and whether it operates in a vacuum or open air.

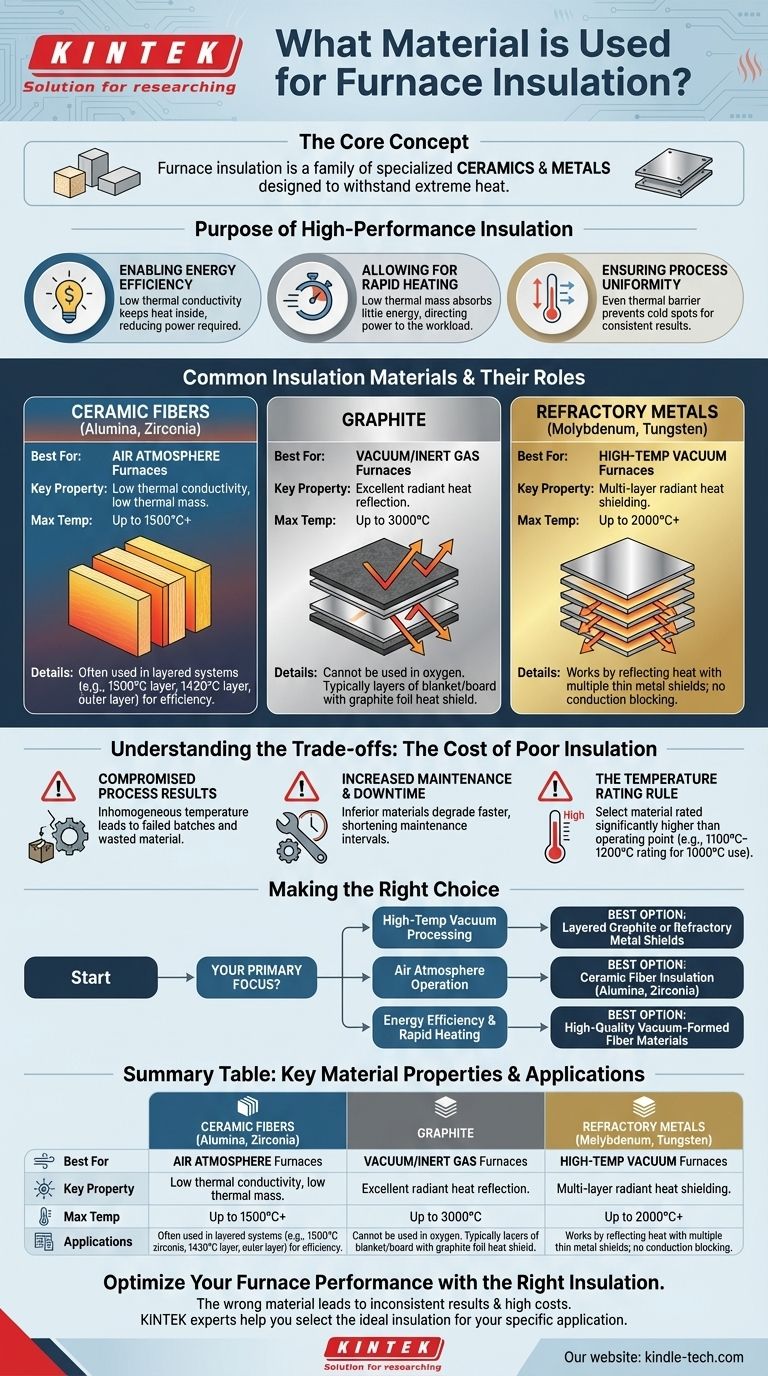

The Purpose of High-Performance Insulation

Insulation in a high-temperature furnace does more than just keep the heat in. Its quality dictates the overall performance and efficiency of the entire system.

Enabling Energy Efficiency

High-quality insulation materials possess low thermal conductivity, meaning they are very poor at transferring heat. This is the primary mechanism for keeping thermal energy inside the furnace, reducing the power required to maintain a target temperature.

Allowing for Rapid Heating

Materials with low heat storage, or low thermal mass, are essential for fast heating cycles. They absorb very little energy themselves, allowing most of the power to go directly into heating the workload. Vacuum-formed fiber plates are particularly effective in this regard.

Ensuring Process Uniformity

Superior insulation provides an even thermal barrier around the heating chamber. This prevents cold spots and ensures a homogenous temperature distribution, which is critical for achieving consistent and reliable process results.

Common Insulation Materials and Their Roles

Different furnace designs and applications call for different insulation strategies. The choice of material is dictated by temperature and the chemical environment inside the furnace.

Ceramic Fibers (Alumina, Zirconia)

These are the workhorses for furnaces that operate in an air atmosphere. They are commonly supplied as rigid boards, flexible blankets, or custom vacuum-formed shapes.

Often, they are used in a layered system. A three-zone furnace might use a high-grade 1500°C zirconia/ceramic fiber layer closest to the heat, followed by a 1430°C layer, and a final outer layer to maximize thermal efficiency.

Graphite

Graphite is a primary choice for insulation in vacuum furnaces. It cannot be used in the presence of oxygen at high temperatures as it will oxidize and degrade rapidly.

It is typically used as layers of soft blanket or rigid board. Often, a layer of graphite foil is included to act as a heat shield, reflecting thermal radiation back into the hot zone.

Refractory Metals (Molybdenum, Tungsten)

Like graphite, these metals are used exclusively in vacuum or inert gas furnaces. They are extremely resistant to high temperatures but will oxidize in air.

Instead of blocking heat through low conductivity, they work by reflecting it. Insulation consists of multiple, thin metal sheets (shields) separated by small gaps. This multi-layer shield assembly is highly effective at containing radiant heat in all-metal hot zones.

Understanding the Trade-offs: The Cost of Poor Insulation

Choosing an inferior or incorrect insulation material has significant and costly consequences that go far beyond simple heat loss.

Compromised Process Results

Poor insulation leads to inhomogeneous temperature distribution within the furnace. This lack of uniformity can ruin sensitive processes, leading to failed batches and wasted material.

Increased Maintenance and Downtime

Inferior materials degrade faster under thermal stress. This shortens the intervals between required maintenance, increases the risk of unexpected furnace failure, and leads to longer, more expensive periods of downtime.

The Temperature Rating Rule

A critical factor is selecting a material rated for a temperature significantly higher than your typical operating point. If your experiments run at 1000°C, the insulation must be rated for at least 1100°C-1200°C to ensure a long service life and prevent premature failure.

Making the Right Choice for Your Application

Your insulation strategy must be directly aligned with the furnace's primary function.

- If your primary focus is high-temperature vacuum processing: Your best options are layered graphite insulation or reflective heat shields made from molybdenum or tungsten.

- If your primary focus is operating in an air atmosphere: You will need to use ceramic fiber insulation, such as alumina or zirconia, typically installed as multi-layer boards or blankets.

- If your primary focus is energy efficiency and rapid heating: Prioritize high-quality, vacuum-formed fiber materials with low thermal mass and conductivity, as these will heat up and cool down the fastest with the least wasted energy.

Ultimately, the insulation is not an accessory but a foundational component that dictates the furnace's performance, reliability, and operational cost.

Summary Table:

| Material | Best For | Key Property | Max Temperature (Typical) |

|---|---|---|---|

| Ceramic Fibers (Alumina, Zirconia) | Air Atmosphere Furnaces | Low thermal conductivity, low thermal mass | Up to 1500°C+ |

| Graphite | Vacuum/Inert Gas Furnaces | Excellent radiant heat reflection | Up to 3000°C |

| Refractory Metals (Molybdenum, Tungsten) | High-Temp Vacuum Furnaces | Multi-layer radiant heat shielding | Up to 2000°C+ |

Optimize your furnace performance and energy efficiency with the right insulation. The wrong material can lead to inconsistent results, higher energy costs, and increased downtime. At KINTEK, we specialize in high-performance lab equipment and consumables. Our experts can help you select the ideal insulation material—whether ceramic fiber, graphite, or metal shields—for your specific furnace application, temperature, and atmosphere. Contact our team today for a consultation to ensure your processes are reliable, efficient, and cost-effective.

Visual Guide

Related Products

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What are the common uses of vacuum pumps in laboratories? Essential for Filtration, Evaporation & Analysis

- What is basic lining material? The Key to High-Temperature Chemical Compatibility

- How does a drying dish for thin-layer spreading affect tungstic acid dehydration? Optimize Surface Area and Uniformity

- How do rotary vane vacuum pumps work? A Deep Dive into Efficient Vacuum Generation

- Why are alumina grinding balls selected for nanostructured eutectic steel? Ensure Purity and Precision

- How does quartz differ from glass? A Guide to Material Selection for Performance

- What is the purpose of boron nitride spray on graphite foil in titanium hot pressing? Enhance Purity and Release

- What is the function of using alumina trays during HIP? Prevent Fusion & Ensure Material Density