The maximum operating temperature for a high-purity alumina tube is typically between 1750°C and 1800°C (approximately 3182°F to 3272°F). This exceptional thermal stability is why alumina is a default material for components in high-temperature furnaces, kilns, and advanced laboratory equipment. The precise temperature limit, however, is not a single number but is directly dependent on the purity of the material.

While the theoretical maximum temperature for alumina is around 1800°C, the practical and safe operating limit is always dictated by its purity. Lower-purity alumina will have a significantly lower maximum temperature due to the presence of impurities that melt and weaken the structure.

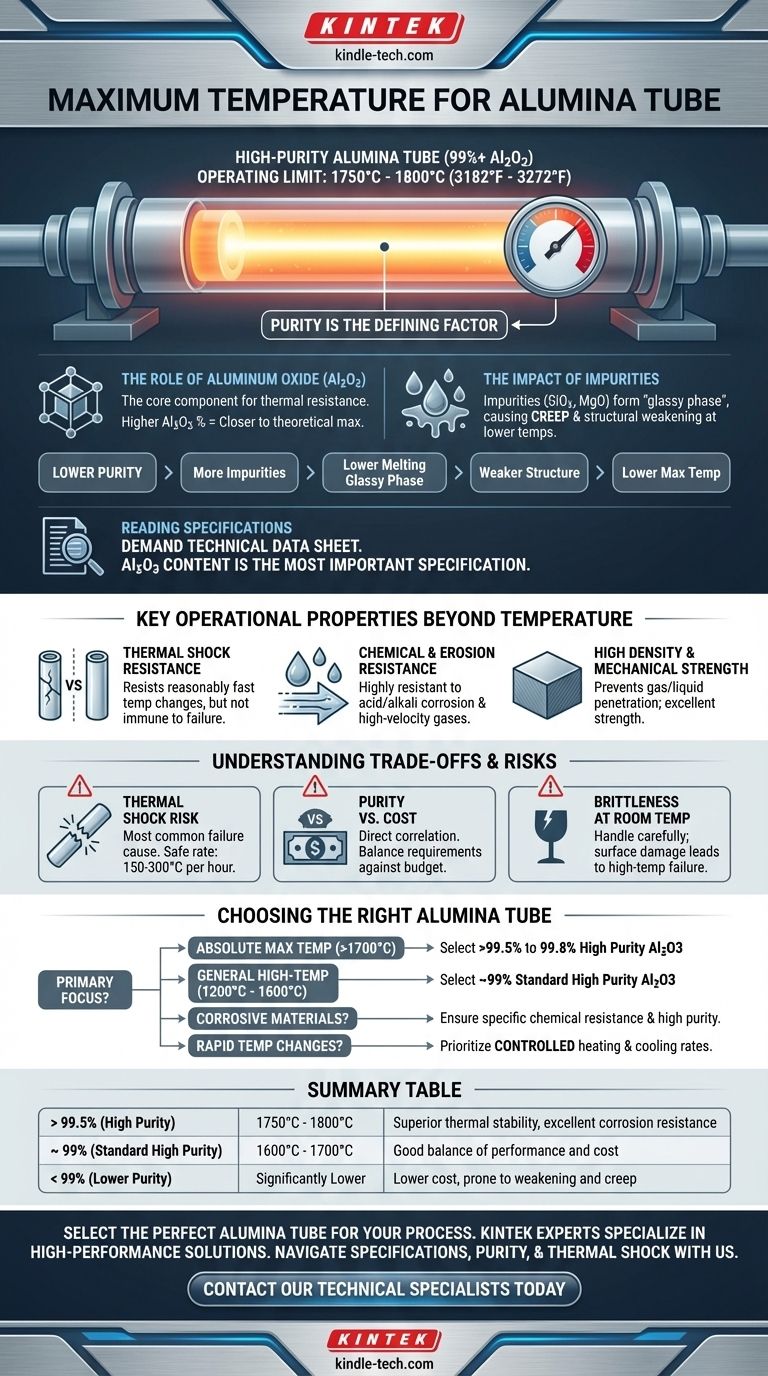

Why Purity is the Defining Factor

The term "alumina" can describe a range of ceramic materials. Understanding the specific composition is critical to determining its true performance capabilities.

The Role of Aluminum Oxide (Al2O3)

The core component responsible for thermal resistance is aluminum oxide (Al2O3). The higher the percentage of Al2O3, the closer the material's performance will be to the theoretical maximum.

For applications requiring temperatures above 1700°C, you should look for tubes specified with high purity, typically greater than 99% Al2O3.

The Impact of Impurities

Impurities, such as silica (SiO2) and magnesia (MgO), are present in lower-grade alumina. These elements form a "glassy phase" at the boundaries between alumina grains.

This glassy phase melts at a much lower temperature than the alumina itself. When it melts, it lubricates the grains, causing the entire ceramic structure to lose its strength and deform, a process known as creep. This can happen hundreds of degrees below the melting point of pure alumina.

Reading the Specifications

Always demand a technical data sheet for any alumina product. A vague label of "alumina tube" is insufficient. The Al2O3 content is the single most important specification for predicting its maximum service temperature.

Key Operational Properties Beyond Temperature

A material's usefulness is defined by more than just its melting point. High-purity alumina possesses several other properties that make it suitable for extreme environments.

Thermal Shock Resistance

Alumina has good resistance to thermal shock, meaning it can handle reasonably fast changes in temperature without cracking. However, it is not immune to failure if heated or cooled too aggressively.

Chemical and Erosion Resistance

The dense, stable crystalline structure of alumina makes it highly resistant to both acid and alkali corrosion. It also stands up well to physical erosion from high-velocity gases.

High Density and Mechanical Strength

High-purity alumina is manufactured to have high density and low porosity. This prevents gases or liquids from penetrating the material and contributes to its excellent mechanical strength, even at high temperatures.

Understanding the Trade-offs and Risks

While alumina is a premier high-temperature material, it has limitations and operational risks that must be managed for successful implementation.

The Risk of Thermal Shock

This is the most common cause of failure for ceramic tubes. A tube heated or cooled too quickly will develop internal stresses that lead to catastrophic cracking. A safe heating and cooling rate is typically in the range of 150-300°C per hour.

Purity vs. Cost

There is a direct correlation between purity and price. A 99.8% alumina tube will be significantly more expensive than a 95% or 99% tube. You must balance the temperature requirements of your application against your budget.

Brittleness at Room Temperature

Like all ceramics, alumina is brittle. It requires careful handling and installation to prevent chipping or cracking before it is even placed into service. Any surface-level damage can become a point of failure at high temperatures.

Choosing the Right Alumina Tube for Your Application

Selecting the correct material is a matter of matching its properties to the specific demands of your process.

- If your primary focus is reaching the absolute maximum temperature (>1700°C): Prioritize alumina tubes with the highest purity available, typically specified as 99.5% to 99.8% Al2O3.

- If your primary focus is general high-temperature use (1200°C to 1600°C): A standard high-purity alumina (around 99%) offers an excellent balance of performance and cost.

- If your process involves corrosive materials: Ensure your chosen alumina grade has documented resistance to the specific chemicals you are using, as purity also affects chemical stability.

- If your process involves rapid temperature changes: You must prioritize controlled heating and cooling rates over simply reaching the maximum temperature to avoid thermal shock failure.

Understanding the direct relationship between purity and performance empowers you to select the precise material for a safe and successful outcome.

Summary Table:

| Alumina Purity (Al2O3 %) | Typical Maximum Operating Temperature | Key Characteristics |

|---|---|---|

| > 99.5% (High Purity) | 1750°C - 1800°C | Superior thermal stability, excellent corrosion resistance |

| ~ 99% (Standard High Purity) | 1600°C - 1700°C | Good balance of performance and cost |

| < 99% (Lower Purity) | Significantly Lower | Lower cost, but prone to weakening and creep at high temperatures |

Select the perfect alumina tube for your high-temperature process.

Choosing the right alumina tube is critical for the safety and success of your application. The experts at KINTEK specialize in high-performance lab equipment and consumables. We can help you navigate the specifications—from purity levels to thermal shock resistance—to ensure you get a solution that meets your exact temperature and budget requirements.

Contact our technical specialists today to discuss your project needs and discover how KINTEK's high-purity alumina tubes can enhance your laboratory's capabilities and reliability.

Visual Guide

Related Products

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

- High Temperature Aluminum Oxide (Al2O3) Protective Tube for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

People Also Ask

- What is the heating rate for alumina tubes? A Variable Schedule to Prevent Thermal Shock

- What is a tube furnace used for? Precision Heating for Material Synthesis & Analysis

- What advantages does a vacuum tube sintering furnace offer for ceramic hollow fiber membranes? Enhance Performance.

- What is the difference between quartz tube and glass tube? Choose the Right Material for Extreme Conditions

- How do you clean an alumina tube furnace? Extend Tube Life with Proper Maintenance

- How does a tube furnace optimize TiC-reinforced steel composites? Achieve the Perfect Balance of Hardness and Strength

- How does an industrial tube furnace ensure the required process conditions for supercritical fluid experimental devices?

- Why is a multi-channel flow-controlled gas tube furnace necessary for g-CNTs? Master Graphene-Nanotube Synthesis