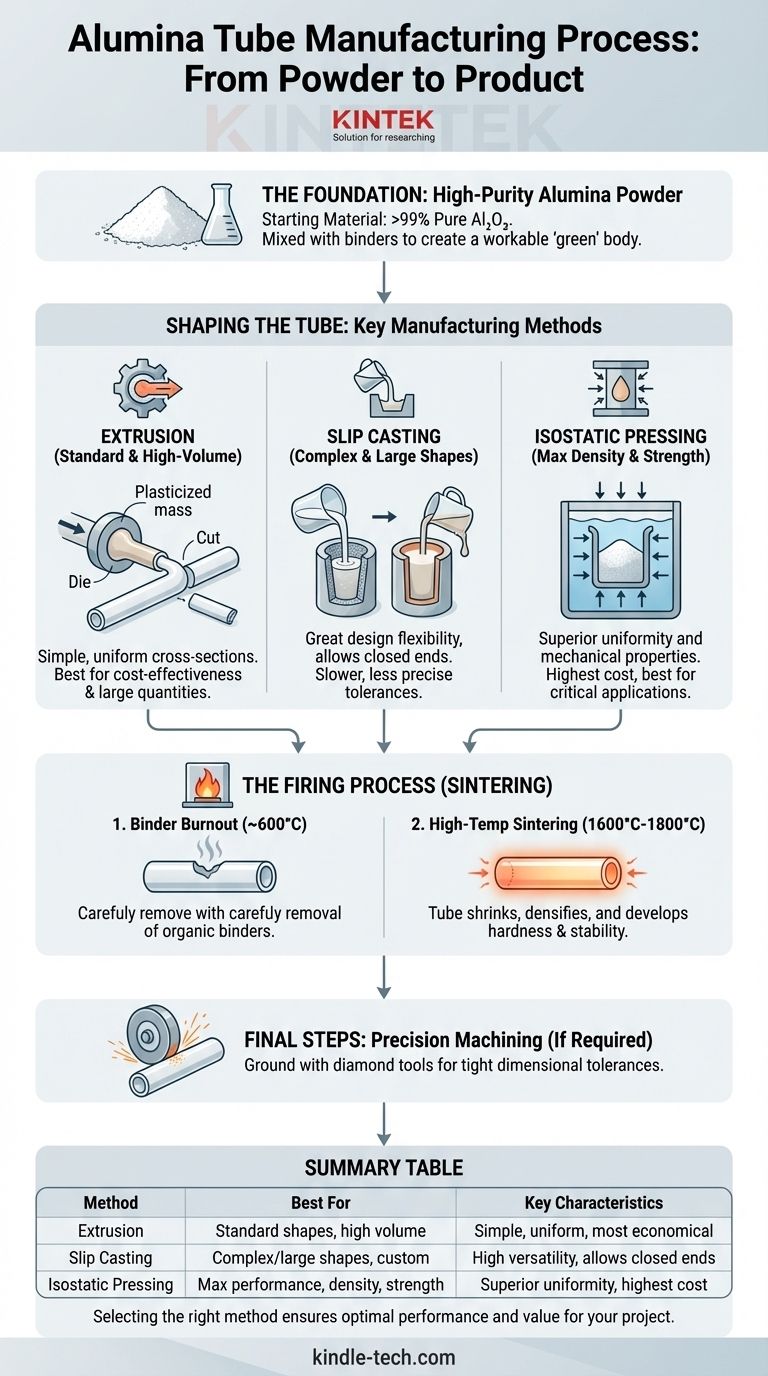

At its core, the manufacturing of an alumina tube is a ceramic-forming process that transforms high-purity aluminum oxide (Al₂O₃) powder into a solid, dense, and highly resilient shape. This is achieved by first mixing the powder with binders to create a workable mass, forming this "green" body into a tube using one of several methods, and finally firing it at extremely high temperatures in a process called sintering. The specific forming method chosen is a critical decision that dictates the tube's final properties and cost.

The manufacturing method used to create an alumina tube—primarily extrusion, slip casting, or isostatic pressing—is not just a production detail. It is the single most important factor determining the tube's density, dimensional accuracy, and mechanical strength, directly impacting its performance in a high-temperature or high-purity application.

The Foundation: High-Purity Alumina Powder

Starting with the Right Material

The entire process begins with exceptionally pure aluminum oxide (Al₂O₃) powder. For high-performance applications like furnace tubes and semiconductor components, this purity often exceeds 99%.

This high purity is the source of alumina's key characteristics: excellent chemical resistance, high electrical insulation, and extreme temperature stability.

Preparing the "Green" Body

Raw powder cannot be easily shaped. It must be mixed with water, organic binders, and plasticizers.

This creates a workable, clay-like mass (for extrusion) or a liquid slurry called a "slip" (for slip casting). This un-fired, pliable state is known as the "green" body.

Shaping the Tube: Key Manufacturing Methods

The choice of forming method is a critical engineering decision based on the desired tube dimensions, complexity, and performance requirements.

Extrusion: The Workhorse for Standard Tubes

Extrusion is the most common and cost-effective method for producing simple, uniform tubes.

The plasticized alumina mixture is forced under high pressure through a circular die. This creates a long, continuous tube that is then cut to the desired length. It is ideal for high-volume production of standard protection tubes, insulators, and furnace wire supports.

Slip Casting: For Complex or Large Shapes

Slip casting is used for tubes with non-standard shapes, closed ends, or very large diameters that are impractical for extrusion.

A liquid alumina slurry is poured into a porous plaster mold. The plaster absorbs the water from the slurry, causing a solid layer of alumina to form on the mold's inner surface. Once the desired wall thickness is achieved, the excess slurry is poured out.

Isostatic Pressing: For Maximum Density and Strength

Isostatic pressing produces the highest quality, most uniform, and densest alumina tubes. This method is reserved for the most demanding applications.

Alumina powder is placed in a flexible, tube-shaped mold, which is then submerged in a fluid chamber. Immense, uniform pressure is applied to the fluid, compacting the powder from all directions. This results in an exceptionally dense green body with minimal internal defects.

From "Green" to Finished: The Firing Process

After forming, the "green" tube is fragile and lacks its final ceramic properties. The firing, or sintering, stage transforms it into a hard, dense final product.

The Importance of Binder Burnout

The green tube is first heated slowly to a moderate temperature (around 600°C). This crucial step carefully burns away the organic binders and plasticizers without causing cracks or defects in the tube.

High-Temperature Sintering

The tube is then heated in a furnace to an extreme temperature, typically between 1600°C and 1800°C.

At this temperature, the individual alumina particles fuse together. The tube shrinks significantly (up to 20%) and densifies, eliminating porosity and developing its characteristic hardness, thermal stability, and mechanical strength.

Precision Machining and Finishing

After sintering, the alumina tube is extremely hard. If very tight dimensional tolerances are required, it must be ground to its final size using diamond-coated tools.

Understanding the Trade-offs

Each manufacturing process involves a balance of cost, complexity, and final performance.

Extrusion: Cost vs. Complexity

An extruded tube is highly cost-effective for standard shapes and high volumes. However, this method is limited to simple, uniform cross-sections.

Slip Casting: Versatility vs. Tolerance

Slip casting allows for great design flexibility, enabling complex or large-scale shapes. The trade-off is often a slower process and potentially less precise dimensional tolerances compared to other methods.

Isostatic Pressing: Performance vs. Cost

This method yields tubes with superior density, uniformity, and strength, making them ideal for critical vacuum, turbine, or structural components. This high performance comes at a significantly higher manufacturing cost.

Selecting the Right Tube for Your Application

Understanding the manufacturing process allows you to choose the correct tube based on your specific technical and budget requirements.

- If your primary focus is cost-effectiveness for standard applications (e.g., thermocouple protection tubes, furnace wire supports): An extruded tube provides excellent performance for the lowest cost.

- If your primary focus is a complex shape or a large-diameter tube (e.g., custom furnace liners or crucibles): A slip-cast tube offers the necessary design flexibility.

- If your primary focus is maximum performance under extreme conditions (e.g., high-vacuum furnace components or precision wafer processing): An isostatically pressed tube will deliver the highest density, purity, and mechanical strength required.

By aligning the manufacturing method with your application's demands, you ensure optimal performance and value for your project.

Summary Table:

| Manufacturing Method | Best For | Key Characteristics |

|---|---|---|

| Extrusion | Standard shapes, high volume, cost-effectiveness | Simple, uniform tubes; most economical |

| Slip Casting | Complex/large shapes, custom designs | High versatility; allows for closed ends and large diameters |

| Isostatic Pressing | Maximum performance, density, and strength | Superior uniformity and mechanical properties; highest cost |

Need a high-performance alumina tube tailored for your lab's specific application? The right manufacturing method is critical for achieving the thermal stability, chemical resistance, and mechanical strength your processes demand. At KINTEK, we specialize in supplying precision lab equipment and consumables, including alumina tubes engineered for reliability. Let our experts help you select the perfect tube for your furnace, semiconductor, or research application. Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- High Purity Alumina Granulated Powder for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina (Al₂O₃) Ceramic Positioning Pin Straight Bevel for Precision Applications

People Also Ask

- Why are ceramics more resistant to corrosion? Unlock the Secret to Unmatched Chemical Stability

- Why is an alumina insulation disk required in a CCPD reactor? Enhance Coating Quality with Floating Potential

- What functions do high-purity alumina support rods serve in sCO2 experiments? Ensure High-Temp Material Integrity

- What are the functions of spring-loaded alumina ceramic rods? Ensure Data Purity in Electrode Test Assemblies

- What is the maximum temperature for alumina tube? Unlock Its Full Potential with High Purity