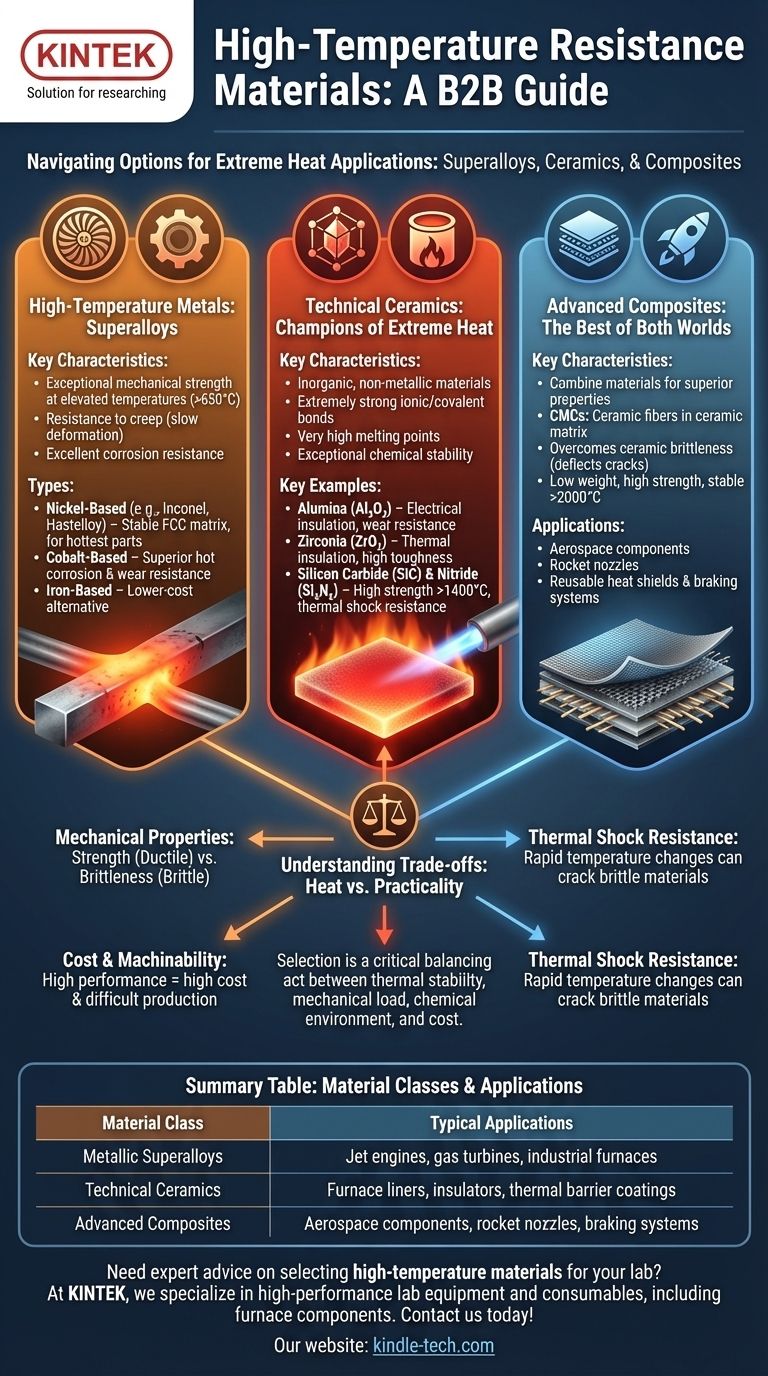

For high-temperature applications, the most common materials are metallic superalloys, technical ceramics, and advanced composites. These material classes are specifically engineered to maintain their structural integrity, mechanical strength, and chemical resistance at temperatures where conventional steels and polymers would fail.

The selection of a high-temperature material is never about a single metric like melting point. It is a critical balancing act between thermal stability, mechanical load, chemical environment, and manufacturing cost. The optimal choice is always dictated by the specific demands of the application.

High-Temperature Metals: Superalloys

Superalloys are metallic alloys designed to retain exceptional mechanical strength, resistance to creep (slow deformation under stress), and corrosion resistance at elevated temperatures, often above 650°C (1200°F).

What Defines a Superalloy?

Unlike standard metals that soften rapidly with heat, superalloys possess a highly stable crystal structure. This allows them to function reliably under significant mechanical stress close to their melting points.

Nickel-Based Superalloys

These are the most common type, with Inconel and Hastelloy being well-known trade names. Their high-temperature strength is derived from a stable face-centered cubic matrix, making them indispensable for the hottest sections of jet engines and gas turbines.

Cobalt and Iron-Based Superalloys

Cobalt-based superalloys offer superior hot corrosion and wear resistance, often used in industrial turbines. Iron-based superalloys provide a lower-cost alternative for applications that are less demanding but still require performance beyond stainless steels.

Technical Ceramics: Champions of Extreme Heat

Technical, or engineering, ceramics are inorganic, non-metallic materials processed for specific functional requirements, including extreme temperature and chemical resistance.

The Power of Strong Atomic Bonds

Ceramics like alumina, zirconia, and silicon carbide have extremely strong ionic and covalent bonds. These bonds require immense energy to break, which translates directly into very high melting points and exceptional chemical stability at temperatures far exceeding the limits of any metal.

Key Examples and Properties

- Alumina (Al₂O₃): A widely used and cost-effective ceramic, valued for its high-temperature electrical insulation and wear resistance.

- Zirconia (ZrO₂): Offers excellent thermal insulation and relatively high fracture toughness for a ceramic, often used in thermal barrier coatings on turbine blades.

- Silicon Carbide (SiC) & Silicon Nitride (Si₃N₄): These maintain very high strength at extreme temperatures (over 1400°C) and exhibit excellent thermal shock resistance. They are used in furnace components, bearings, and automotive parts.

Advanced Composites: The Best of Both Worlds

Composites combine two or more distinct materials to create a new material with superior properties. For high-temperature use, Ceramic Matrix Composites (CMCs) and Carbon-Carbon composites are at the forefront.

Overcoming Ceramic Brittleness

The primary weakness of monolithic ceramics is their brittleness. Ceramic Matrix Composites (CMCs) embed ceramic fibers (like silicon carbide) within a ceramic matrix. This structure deflects cracks, providing a toughness and damage tolerance that monolithic ceramics cannot achieve.

Pushing Aerospace Boundaries

Materials like Carbon-Carbon (C/C) and SiC-SiC composites offer low weight, high strength, and stability at temperatures over 2000°C. They are essential for applications like rocket nozzles, reusable heat shields for spacecraft, and high-performance braking systems.

Understanding the Trade-offs: Heat vs. Practicality

Selecting a high-temperature material involves navigating a complex set of compromises. The ideal "heatproof" material rarely exists in isolation from its practical limitations.

Mechanical Properties: Strength vs. Brittleness

Superalloys are ductile; they bend before they break, providing a margin of safety. Ceramics are extremely strong under compression but are brittle and can fail catastrophically under tension or impact without warning.

Cost and Machinability

High-performance materials come at a high cost. Superalloys and technical ceramics are expensive to produce and notoriously difficult to machine, requiring specialized tools and processes that significantly increase manufacturing expenses.

Thermal Shock Resistance

Rapid temperature changes can create internal stresses that crack brittle materials. While some ceramics like silicon nitride are engineered for it, thermal shock remains a key failure mode for many ceramic components, a problem less severe in ductile superalloys.

Selecting the Right Material for Your Application

Your choice must be guided by a clear hierarchy of your project's operational demands.

- If your primary focus is mechanical strength and ductility below 1200°C: Nickel- or cobalt-based superalloys are the industry standard for rotating and structural parts.

- If your primary focus is extreme temperature stability (>1400°C) with low mechanical stress: Technical ceramics like Alumina or Zirconia are excellent for insulators, furnace liners, and chemical crucibles.

- If your primary focus is high-temperature strength AND fracture toughness: Ceramic Matrix Composites (CMCs) are the leading choice for cutting-edge aerospace applications where failure is not an option.

- If your primary focus is cost-effectiveness for moderate heat and corrosion resistance: High-strength stainless steels or iron-based superalloys offer a practical compromise.

Understanding these material classes and their inherent trade-offs is the key to successful high-temperature design.

Summary Table:

| Material Class | Key Characteristics | Typical Applications |

|---|---|---|

| Metallic Superalloys | High strength, creep resistance, ductile | Jet engines, gas turbines, industrial furnaces |

| Technical Ceramics | Extreme heat resistance, chemical stability, brittle | Furnace liners, insulators, thermal barrier coatings |

| Advanced Composites | High strength-to-weight ratio, thermal stability, tough | Aerospace components, rocket nozzles, braking systems |

Need expert advice on selecting high-temperature materials for your lab?

At KINTEK, we specialize in providing high-performance lab equipment and consumables, including furnace components made from advanced ceramics and superalloys. Our experts can help you choose the right materials to enhance your lab's efficiency and safety.

Contact us today to discuss your specific high-temperature application requirements!

Visual Guide

Related Products

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Thermally Evaporated Tungsten Wire for High Temperature Applications

- Custom PTFE Teflon Parts Manufacturer F4 Conical Flask Triangular Flask 50 100 250ml

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

People Also Ask

- What is target in sputtering? The Essential Source Material for Thin-Film Deposition

- What happens during sintering? Transform Powder into Dense, Strong Components

- What is the end product of plastic waste? The Alarming Truth About Its Final Destination

- What are the applications of optical thin film? Unlocking Precision Light Control

- What is the difference between a wet and dry vacuum system? Choose the Right Technology for Your Process Purity

- What is the specific heat capacity for melting? Clarifying Latent Heat vs. Specific Heat

- What is the conductivity of graphite? Understanding Its High Electrical & Thermal Properties

- What is a filter press used for? Achieve Maximum Solid-Liquid Separation Efficiency