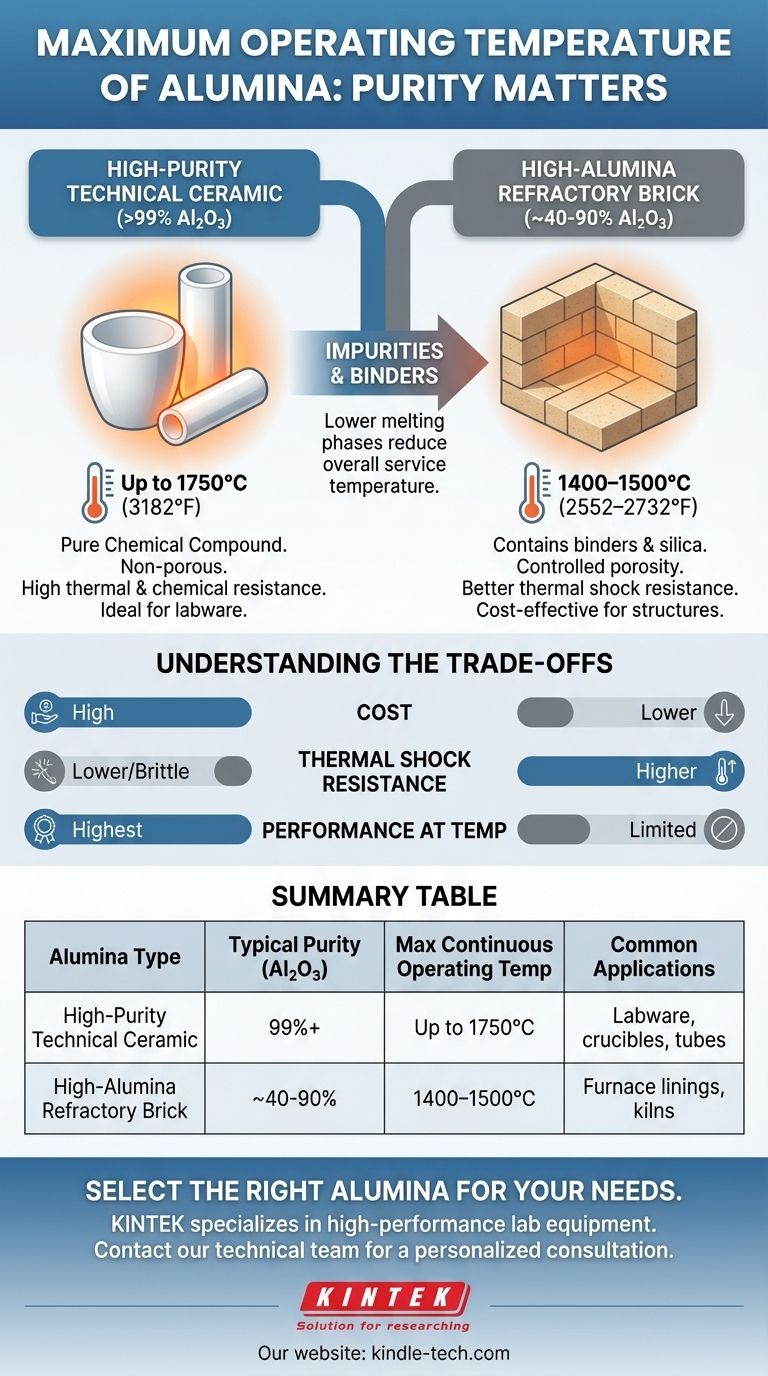

The maximum operating temperature of alumina is not a single number but a range that depends critically on the material's purity and form. While high-purity, dense alumina can be used continuously at temperatures up to 1750°C (3182°F), common refractory products like high-alumina bricks are typically limited to a lower range of 1400–1500°C (2552–2732°F).

The difference in temperature rating comes down to one key factor: impurities. The 1750°C figure applies to high-purity, dense technical ceramics, whereas the lower figures apply to refractory materials that contain binders and other elements which reduce the overall service temperature.

Why Purity Dictates Temperature Resistance

The term "alumina" can describe a pure chemical compound (Al₂O₃) or a family of ceramic materials where Al₂O₃ is the primary component. This distinction is the source of the different temperature ratings.

The Standard for High-Purity Alumina

For applications demanding the highest performance, technical-grade alumina with a purity of 99% or greater is used. These are typically fully dense, non-porous ceramics.

While the theoretical melting point of pure alumina is approximately 2072°C (3762°F), its practical maximum continuous operating temperature is around 1750°C. Operating above this risks deformation under load (creep) and degradation over time.

The Impact of Binders and Impurities

Many alumina products, especially structural refractories like kiln bricks, are not pure Al₂O₃. They are "high-alumina," meaning Al₂O₃ is the main ingredient, but they also contain significant amounts of other materials like silica (SiO₂) and various mineral binders.

These additives lower the manufacturing cost and can improve properties like thermal shock resistance. However, they also form phases within the ceramic that melt at much lower temperatures, reducing the material's overall service limit to the 1400–1500°C range.

Understanding the Trade-offs

Choosing the right alumina requires balancing performance needs against practical constraints. Simply selecting the material with the highest temperature rating is not always the best or most economical solution.

Purity vs. Cost

There is a direct and steep correlation between the purity of alumina and its cost. Manufacturing 99.5%+ pure, dense alumina components is a far more energy-intensive and controlled process than producing refractory bricks.

Performance vs. Thermal Shock

Dense, high-purity alumina, while strong at high temperatures, can be brittle and susceptible to cracking if heated or cooled too quickly (thermal shock). Refractory bricks are often engineered with controlled porosity that helps them better withstand these rapid temperature changes.

The Importance of the Datasheet

Never assume a temperature rating. The manufacturer's technical datasheet is the definitive source of truth. It will specify the exact alumina percentage, density, and, most importantly, the recommended maximum service temperature for that specific product.

Making the Right Choice for Your Application

Your goal determines which type of alumina is appropriate.

- If your primary focus is maximum thermal and chemical resistance for labware (e.g., crucibles, tubes): You need a high-purity (99%+) dense alumina ceramic specified for service up to 1750°C.

- If your primary focus is building a structural furnace or kiln lining: High-alumina refractory bricks rated for 1400–1500°C offer the best balance of thermal insulation, structural integrity, and cost-effectiveness.

- If your primary focus is any high-temperature application: Always verify the material's specifications on its technical datasheet before purchase and use.

Understanding the relationship between purity, form, and performance is the key to selecting the correct alumina for your high-temperature needs.

Summary Table:

| Alumina Type | Typical Purity (Al₂O₃) | Max Continuous Operating Temperature | Common Applications |

|---|---|---|---|

| High-Purity Technical Ceramic | 99%+ | Up to 1750°C (3182°F) | Labware, crucibles, tubes |

| High-Alumina Refractory Brick | ~40-90% | 1400–1500°C (2552–2732°F) | Furnace linings, kilns |

Selecting the right alumina is critical for your lab's safety and performance.

KINTEK specializes in high-performance lab equipment and consumables. Our experts can help you choose the perfect high-purity alumina crucibles, tubes, or furnace linings based on your specific temperature and application requirements.

Ensure optimal results and equipment longevity. Contact our technical team today for a personalized consultation!

Visual Guide

Related Products

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- High Quality Alumina Ceramic Screw for Engineering Advanced Fine Ceramics with High Temperature Resistance and Insulation

- High Purity Alumina Granulated Powder for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

People Also Ask

- How much temperature can porcelain withstand? Unlock Its True Heat Resistance & Avoid Thermal Shock

- How do ceramic insulators contribute to SHS experimental safety? Enhance Your Lab’s Ignition Precision and Protection

- What is the type of silicon carbide? A Guide to Polymorphs, Grades, and Applications

- At what temperature does ceramic melt? A Guide to Ceramic Heat Resistance

- What are the roles of sintering additives? Master the Process for Superior Material Performance

- What is the process of alumina tube manufacturing? From Powder to High-Performance Ceramic

- Why ceramics can withstand high temperature? Unlock the Secrets of Atomic Structure

- Why are alumina ceramic discs used as sample supports? Optimize Cathodic Cage Deposition Efficiency