In any milling operation, the grinding media is the active agent of size reduction. It serves as the direct mechanism for transferring energy from the mill to the material being processed. The properties of this media, primarily its size, are the most critical factors governing overall milling efficiency, which is measured in both particle breakage effectiveness and power consumption.

The core principle of efficient milling is not about using the biggest or smallest media, but about matching the media's impact energy to the specific breakage requirements of the material. The right media delivers just enough energy to fracture particles effectively without wasting power on ineffective collisions.

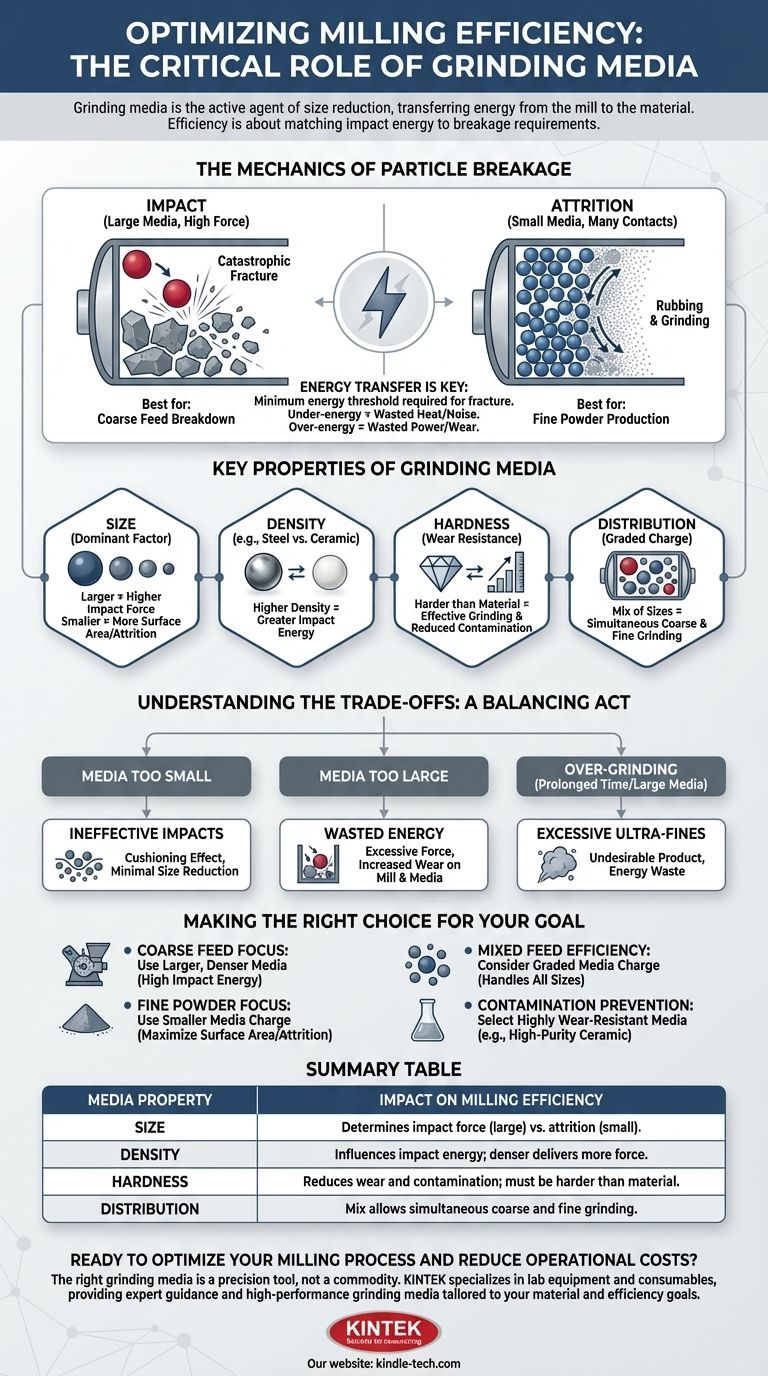

The Mechanics of Particle Breakage

To understand efficiency, we must first understand how grinding media works. The media acts as a bridge, converting the bulk rotational energy of the mill into localized, high-energy events that break down particles.

Impact vs. Attrition

There are two primary mechanisms of size reduction. Impact occurs when large pieces of media fall and strike the material, causing catastrophic fracture. Attrition (or abrasion) is the rubbing and grinding action that occurs as media and particles slide against each other, which is better for producing very fine powders.

The Role of Media Size

The size of the grinding media directly determines which of these mechanisms is dominant.

Larger media, when lifted by the mill's rotation, falls with greater force, creating high-energy impacts. This is essential for breaking down large, coarse feed material.

Smaller media has less mass and generates lower-impact forces. However, a charge of smaller media has a vastly greater number of contact points and total surface area, promoting the attrition needed for fine grinding.

Energy Transfer is Key

Every particle requires a certain minimum amount of energy to create a fracture. If the impact energy from the media is below this threshold, no breakage occurs, and the energy is wasted as heat and noise. If the energy is far too high, it can be wasted in over-grinding or causing unnecessary wear on the mill lining.

Key Properties of Grinding Media

While size is the dominant factor, a complete picture of efficiency requires considering other properties that fine-tune the milling process.

Media Density

The density of the media material (e.g., steel vs. ceramic) directly influences the impact energy. A denser ball of the same size will strike with more force than a less dense one, making it more effective for breaking hard materials.

Media Hardness

The media must be harder than the material being ground to be effective and to resist wear. Media wear is a direct operational cost and can also introduce unwanted contamination into the final product, a critical concern in industries like pharmaceuticals and food processing.

Media Distribution (The Charge)

In many cases, the most efficient approach is to use a graded charge with a mix of media sizes. Larger balls segregate to handle the coarse feed, while smaller balls work on the finer particles as they are created. This allows the mill to perform coarse and fine grinding simultaneously.

Understanding the Trade-offs

Optimizing milling efficiency is a balancing act. Choosing the wrong media creates significant operational problems and wastes resources.

The Problem of Ineffective Impacts

Using media that is too small for the feed material is a common mistake. The particles simply "cushion" the low-energy impacts, leading to minimal size reduction and wasted energy consumption. The mill will run, but it won't be grinding effectively.

The Problem of Wasted Energy

Conversely, using media that is too large for the material is also inefficient. The high-energy impacts may be more than what is needed for fracture, wasting energy. This can also lead to excessive wear on both the media and the mill liners, increasing maintenance costs.

The Risk of Over-Grinding

Using media that is too large or running the mill for too long can create an excessive amount of ultra-fine particles, a phenomenon known as over-grinding. This can be undesirable for the final product and represents a waste of the energy used to create those particles.

Making the Right Choice for Your Goal

Selecting the optimal media requires a clear understanding of your starting material and your desired final product.

- If your primary focus is breaking down coarse feed material: Opt for larger, denser grinding media that provides the high-impact energy necessary for initial fracture.

- If your primary focus is producing a very fine powder: Use a charge of smaller media to maximize surface area and promote the attrition required for fine grinding.

- If your primary focus is maximizing efficiency with a mixed feed size: Consider a graded media charge with a distribution of sizes to handle both coarse and fine particles in a single process.

- If your primary focus is preventing product contamination: Select a highly wear-resistant media, such as high-purity ceramic, even if it means adjusting other parameters to compensate for lower density.

Ultimately, treating your grinding media as a precision tool, not a simple commodity, is the key to unlocking an efficient and cost-effective milling operation.

Summary Table:

| Media Property | Impact on Milling Efficiency |

|---|---|

| Size | Determines impact force (large media) vs. attrition surface area (small media). |

| Density | Influences impact energy; denser media (e.g., steel) delivers more force. |

| Hardness | Reduces wear and contamination; must be harder than the material being ground. |

| Distribution (Graded Charge) | A mix of sizes allows for simultaneous coarse and fine grinding, boosting efficiency. |

Ready to optimize your milling process and reduce operational costs? The right grinding media is a precision tool, not a commodity. KINTEK specializes in lab equipment and consumables, providing expert guidance and high-performance grinding media tailored to your material and efficiency goals. Contact our experts today to discuss your specific application and unlock superior milling performance for your laboratory.

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- Laboratory Jar Mill with Agate Grinding Jar and Balls

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- What is the primary function of a high-energy ball mill? Master Nano-Nickel Synthesis and Material Refinement

- What is the function of an ultrasonic homogenizer in high-entropy metallic glass synthesis? Key to Stoichiometric Control

- Why is the use of zirconia grinding balls necessary? Ensure High Purity and Efficiency in Ceramic Milling

- Why use agate grinding jars for silver vanadium oxide? Ensure Purity in Battery Material Milling

- What is the function of laboratory mills? Achieve Precise Particle Size Control for Accurate Analysis

- What function does a high-speed rotor-stator homogenizer perform in biomass processing? Optimize Structural Disruption

- What is the difference between crushing and pulverization? Design Your Efficient Size Reduction Circuit

- What is the role of a 3D powder mixer in the preparation of metal-ceramic composites? Achieve Perfect Homogeneity