In short, sieve analysis is a foundational technique used to determine the particle size distribution of a wide range of granular materials. It is suitable for quality control and material characterization in industries from civil engineering and manufacturing to pharmaceuticals and agriculture, providing a reliable way to verify that a material meets specific physical requirements.

Sieve analysis is not simply about measuring particles. It is a critical process for confirming that a material's physical composition aligns with the precise specifications demanded by its intended application, ensuring performance, safety, and consistency.

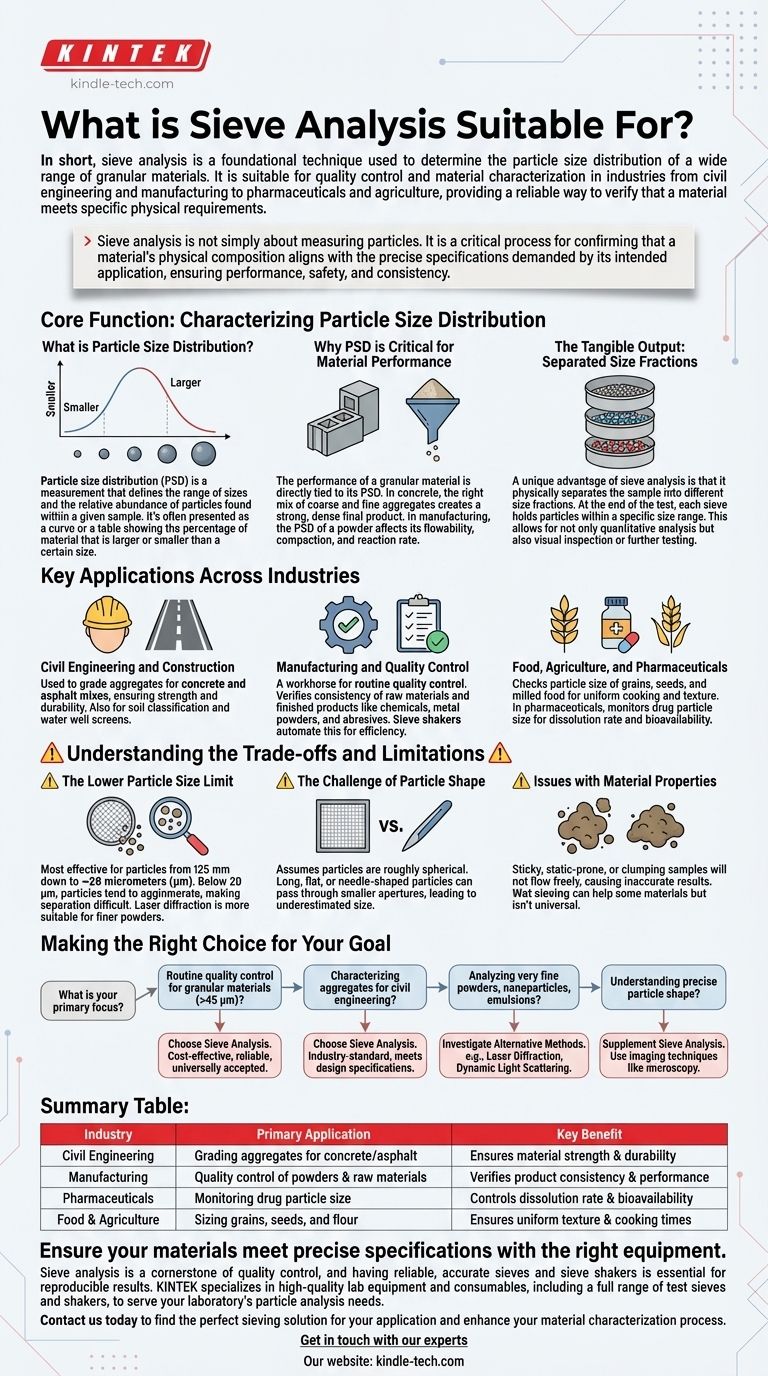

Core Function: Characterizing Particle Size Distribution

What is Particle Size Distribution?

Particle size distribution (PSD) is a measurement that defines the range of sizes and the relative abundance of particles found within a given sample. It's often presented as a curve or a table showing the percentage of material that is larger or smaller than a certain size.

This data is the primary output of a sieve analysis. It provides a quantitative fingerprint of the material's physical structure.

Why PSD is Critical for Material Performance

The performance of a granular material is directly tied to its PSD. In concrete, the right mix of coarse and fine aggregates creates a strong, dense final product. In manufacturing, the PSD of a powder affects its flowability, compaction, and reaction rate.

By controlling the PSD, you control the end-use properties of the material. Sieve analysis is the tool used to verify this control.

The Tangible Output: Separated Size Fractions

A unique advantage of sieve analysis is that it physically separates the sample into different size fractions. At the end of the test, each sieve holds particles within a specific size range.

This allows for not only quantitative analysis but also visual inspection or further testing on specific size fractions if needed.

Key Applications Across Industries

Civil Engineering and Construction

This is a classic application for sieve analysis. It is used to grade aggregates for concrete and asphalt mixes, ensuring the final product has the required strength and durability.

The method is also used for soil classification and to size screens for water production wells, ensuring optimal flow and filtration.

Manufacturing and Quality Control

In industrial settings, sieve analysis is a workhorse for routine quality control. It verifies the consistency of raw materials and finished products like chemicals, metal powders, and abrasives.

Using a sieve shaker automates this process, providing accurate and reproducible results quickly, which is essential in a production environment.

Food, Agriculture, and Pharmaceuticals

Sieve analysis is used to check the particle size of grains, seeds, and milled food products like flour. This ensures uniform cooking times and consistent product texture.

In pharmaceuticals, particle size is critical for a drug's dissolution rate and bioavailability. Sieve analysis provides a simple method for monitoring this key parameter.

Understanding the Trade-offs and Limitations

The Lower Particle Size Limit

Sieve analysis is most effective for particles ranging from 125 millimeters down to approximately 20 micrometers (µm).

Below 20 µm, particles tend to agglomerate, and electrostatic forces can cause them to stick to the sieve mesh, making accurate separation difficult. For these finer powders, methods like laser diffraction are more suitable.

The Challenge of Particle Shape

The fundamental assumption of sieve analysis is that particles are roughly spherical. The test measures whether a particle can pass through a square opening.

Long, flat, or needle-shaped particles can pass through apertures that are smaller than their actual length. This can lead to an underestimation of their true size and skew the distribution results.

Issues with Material Properties

Some materials are inherently difficult to sieve. Samples that are sticky, prone to static charge, or form clumps (agglomerate) will not flow freely through the sieve stack, leading to inaccurate results.

While wet sieving can overcome some of these issues for materials that are unaffected by liquid, it is not a universal solution.

Making the Right Choice for Your Goal

Deciding if sieve analysis is the correct method depends entirely on your material and your objective.

- If your primary focus is routine quality control for granular materials (>45 µm): Sieve analysis is the most cost-effective, reliable, and universally accepted method.

- If your primary focus is characterizing aggregates for civil engineering projects: This is the industry-standard method required to ensure materials meet design specifications.

- If your primary focus is analyzing very fine powders, nanoparticles, or emulsions: You should investigate alternative methods like laser diffraction or dynamic light scattering.

- If your primary focus is understanding the precise shape of your particles: Sieve analysis should be supplemented with imaging techniques like microscopy.

Ultimately, sieve analysis provides a reliable and accessible way to ensure your material's physical structure is fit for its intended purpose.

Summary Table:

| Industry | Primary Application | Key Benefit |

|---|---|---|

| Civil Engineering | Grading aggregates for concrete/asphalt | Ensures material strength & durability |

| Manufacturing | Quality control of powders & raw materials | Verifies product consistency & performance |

| Pharmaceuticals | Monitoring drug particle size | Controls dissolution rate & bioavailability |

| Food & Agriculture | Sizing grains, seeds, and flour | Ensures uniform texture & cooking times |

Ensure your materials meet precise specifications with the right equipment.

Sieve analysis is a cornerstone of quality control, and having reliable, accurate sieves and sieve shakers is essential for reproducible results. KINTEK specializes in high-quality lab equipment and consumables, including a full range of test sieves and shakers, to serve your laboratory's particle analysis needs.

Contact us today to find the perfect sieving solution for your application and enhance your material characterization process.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Single Horizontal Jar Mill

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis

- What are the factors affecting sieving performance and efficiency? Optimize Your Particle Separation Process

- What is the role of standard sieves in gold scrap leaching kinetic studies? Ensure Precision in Particle Classification

- Why is sieve analysis important? Ensure Consistent Quality and Performance of Your Materials