At its core, the significance of a hand sieve shaker is its ability to standardize the process of particle size analysis. It replaces inconsistent, manual shaking with a mechanized, repeatable motion, ensuring that results are reliable, comparable, and independent of the operator.

Manually sieving materials is prone to human error, leading to unreliable data. A hand sieve shaker solves this by providing a consistent mechanical action, which is the foundation for accurate and repeatable particle size testing in quality control and research.

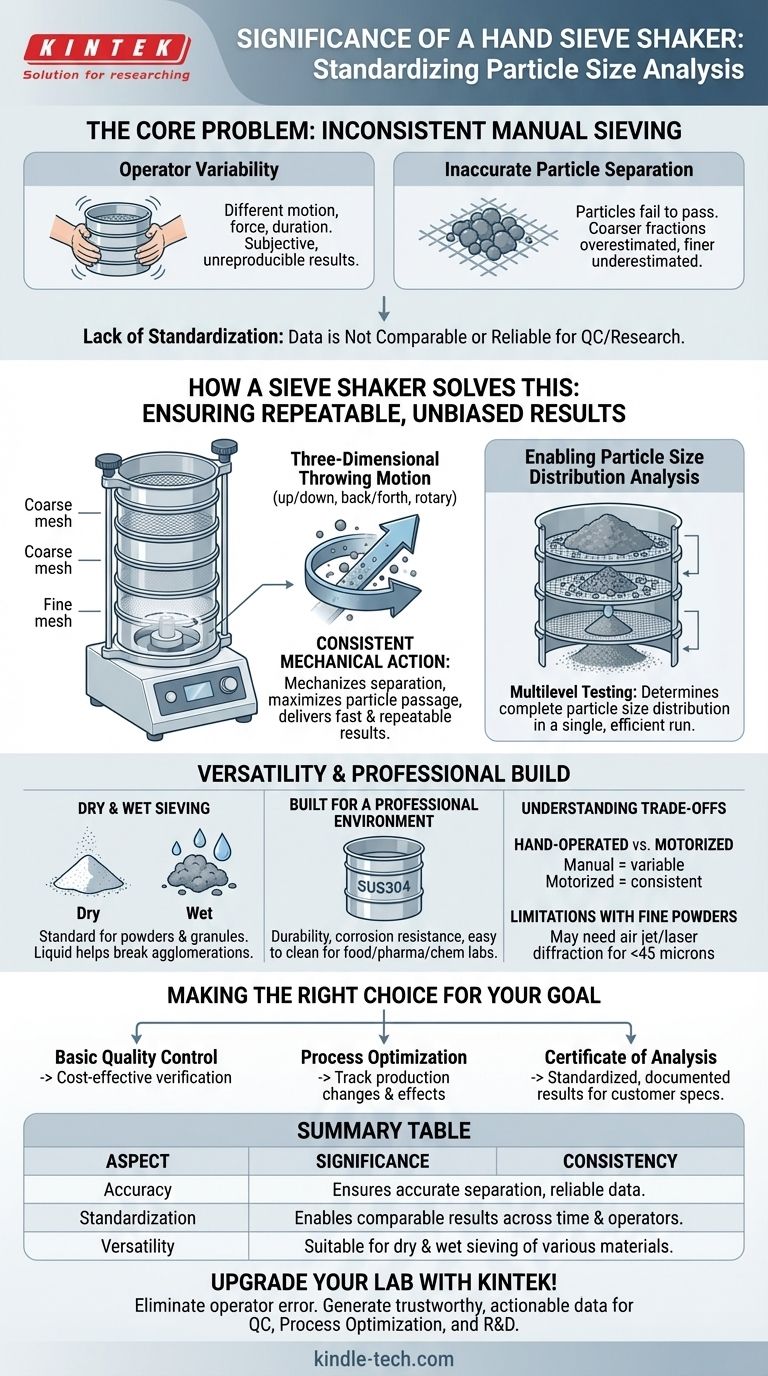

The Core Problem: Inconsistent Manual Sieving

Operator Variability

When a person shakes a set of sieves by hand, the exact motion, force, and duration are impossible to replicate perfectly every time.

Different operators will naturally shake the sieves differently, leading to significant variations in the results for the same sample of material.

Inaccurate Particle Separation

Inconsistent shaking means some particles may not be given a sufficient opportunity to pass through the mesh openings.

This can result in an inaccurate particle size distribution, where coarser fractions are overestimated and finer fractions are underestimated.

Lack of Standardization

For quality control or scientific research, data must be comparable over time and between different labs.

Manual sieving makes this impossible, as there is no standard to follow. The results are subjective and cannot be reliably used for certification or process control.

How a Sieve Shaker Solves This

Ensuring Repeatable, Unbiased Results

A sieve shaker mechanizes the separation process using a consistent and uniform motion.

Many shakers employ a three-dimensional throwing motion, which lifts and turns the material, ensuring particles are constantly reintroduced to the sieve surface from different angles. This maximizes the chance for each particle to pass through an opening.

This mechanical consistency delivers fast and repeatable results, forming the basis of any reliable particle analysis program.

Enabling Particle Size Distribution Analysis

A key function of a sieve shaker is its ability to agitate a stack of multiple sieves at once.

Each sieve in the stack has a progressively smaller mesh size. As the shaker operates, the material is sorted through the layers, from coarsest at the top to finest at the bottom.

This multilevel testing allows you to determine the complete particle size distribution of a sample in a single, efficient run.

Versatility for Different Materials

Sieve shakers are designed for both wet and dry sieving.

Dry sieving is the standard for free-flowing powders and granules. Wet sieving is used for materials that tend to clump or agglomerate, where a liquid (usually water) helps break up particles and wash them through the mesh.

Built for a Professional Environment

Professional-grade shakers are often constructed from materials like SUS304 stainless steel.

This provides durability, resistance to corrosion, and makes the equipment easy to clean, which is critical in food, pharmaceutical, and chemical laboratory environments.

Understanding the Trade-offs

Hand-Operated vs. Motorized

The term "hand sieve shaker" can refer to a manual, crank-operated device or, more commonly, a simple, portable motorized shaker.

Manual versions are cheaper but reintroduce some operator variability. Simple motorized versions offer consistency but may lack the advanced controls (like variable amplitude and frequency) of high-end laboratory shakers.

Limitations with Very Fine Powders

For extremely fine powders (typically below 45 microns), simple mechanical shaking may not be energetic enough to overcome forces of static electricity and particle agglomeration.

In these cases, more advanced techniques like air jet sieving or laser diffraction may be required for accurate results.

Throughput and Scale

Benchtop sieve shakers are ideal for quality control, batch testing, and research and development. They are not designed for high-volume, continuous industrial screening.

Making the Right Choice for Your Goal

A hand sieve shaker is an essential tool for bringing objectivity to particle analysis. To decide if it fits your needs, consider your primary objective.

- If your primary focus is basic quality control: A sieve shaker is a cost-effective and indispensable tool for verifying the consistency of raw materials or finished products.

- If your primary focus is process optimization: The repeatable data allows you to track how changes in your production process affect particle size distribution.

- If your primary focus is generating a Certificate of Analysis: A sieve shaker provides the standardized, documented results required to certify that your material meets customer specifications.

Ultimately, adopting a sieve shaker is the first step toward transforming subjective observation into reliable, actionable data.

Summary Table:

| Aspect | Significance |

|---|---|

| Consistency | Replaces inconsistent manual shaking with a mechanized, repeatable motion. |

| Accuracy | Ensures accurate particle separation for reliable size distribution data. |

| Standardization | Enables comparable results over time and between different operators or labs. |

| Versatility | Suitable for both wet and dry sieving of various materials. |

Upgrade your lab's particle analysis with KINTEK!

Are inconsistent manual sieving methods compromising your quality control data? KINTEK specializes in reliable lab equipment, including sieve shakers designed to deliver the standardized, repeatable results you need for certification, process optimization, and R&D.

Our solutions help you eliminate operator error and generate trustworthy, actionable data. Contact us today to find the perfect particle size analysis equipment for your laboratory needs.

Get a Quote & Discuss Your Needs

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

People Also Ask

- What are the factors affecting sieving performance and efficiency? Optimize Your Particle Separation Process

- What is the primary purpose of using standard sieves? Master Particle Uniformity for High-Quality Catalyst Preparation

- How is a vibratory sieve shaker used in the particle size analysis of mechanically alloyed powders? Expert Guide

- What is the role of standard sieves in gold scrap leaching kinetic studies? Ensure Precision in Particle Classification

- What are the specifications for test sieves? A Guide to ASTM & ISO Standards for Accurate Particle Analysis