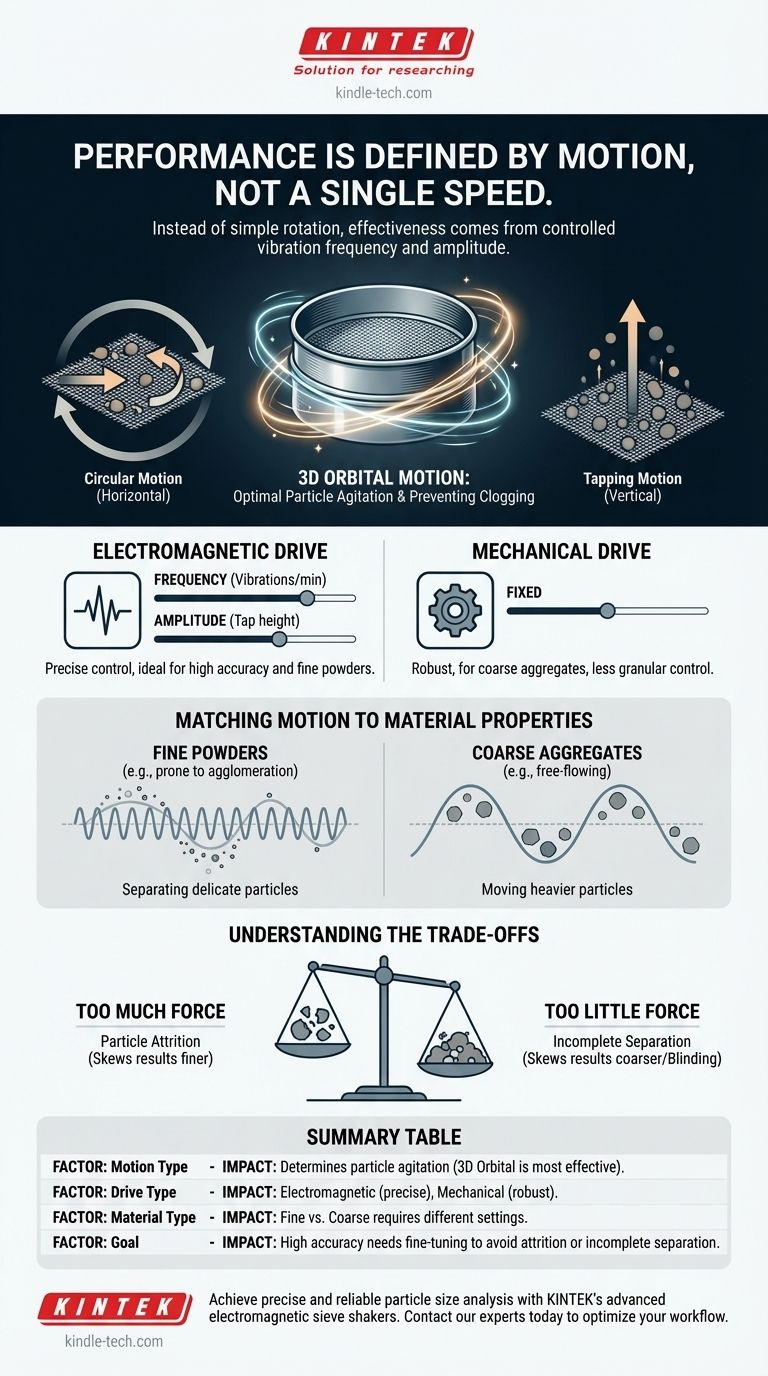

A sieve shaker's performance is defined by its motion, not a single speed. Instead of a simple rotational speed like a motor, its effectiveness comes from a controlled combination of vibration frequency and amplitude, which is adjusted based on the material being analyzed and the desired precision of the results.

The core principle to understand is that a sieve shaker's goal is not speed, but optimal particle agitation. Its effectiveness is determined by the specific type and intensity of its vibratory motion—typically orbital or electromagnetic—which must be matched to the material's characteristics to ensure accurate separation.

Beyond Speed: The Mechanics of Sieve Shaker Motion

To understand why a single "speed" is the wrong metric, you have to look at what the machine is designed to accomplish: making particles find the correct aperture in a stack of sieves. This requires a specific and controlled type of movement.

The Importance of Orbital Motion

The most effective sieve shakers impart a 3D orbital motion. This combines a horizontal, circular movement with a vertical, tapping movement.

This dual action is critical. The circular motion spreads the material across the entire surface of the sieve, while the vertical tap lifts the particles, preventing them from clogging the mesh and giving each particle a chance to pass through an opening.

Electromagnetic vs. Mechanical Drives

The "engine" of the shaker dictates its motion and control. An electromagnetic drive, powered by precise electronic pulses, is standard for high-accuracy applications.

This technology allows for the fine-tuning of both vibration frequency (how many times it vibrates per minute) and amplitude (the intensity or "height" of the tap). Mechanical shakers, while robust, often offer less granular control over these variables.

Key Factors That Determine Shaker Effectiveness

The correct operational settings are not universal. They are a direct response to the physical properties of the sample being tested.

Matching Motion to Material Properties

The characteristics of your material are the most important consideration. Fine powders prone to agglomeration or static electricity require a different setting than coarse, free-flowing aggregates.

A high-frequency, low-amplitude vibration might be needed to gently separate delicate particles, whereas a more powerful, lower-frequency motion may be required for heavier materials.

The Role of the Sieve Stack

A sieve shaker must agitate a tall stack of sieves, often ranging from coarse mesh (e.g., 125 mm) at the top to extremely fine mesh (e.g., 20 microns) at the bottom.

The energy from the shaker must be transmitted consistently through the entire stack to ensure particles are properly sorted at every level.

Understanding the Trade-offs

Simply setting the shaker to its most powerful setting is a common mistake that leads to inaccurate results. Control is more important than raw power.

Too Much Force Damages Particles

Excessive or incorrect vibration can cause particle attrition, where brittle materials break apart during testing. This fracturing skews your results, making the sample appear finer than it actually is.

Too Little Force Prevents Separation

Conversely, insufficient agitation will lead to incomplete separation. Particles won't be lifted and moved adequately, resulting in sieve blinding (clogging) and an inaccurate analysis that shows the material as being coarser than it is.

Making the Right Choice for Your Goal

To achieve accurate and repeatable results, you must tailor the shaker's settings to your specific objective and material type.

- If your primary focus is coarse aggregates: A mechanical shaker with a strong vertical tap and horizontal motion is often sufficient to separate larger, free-flowing particles.

- If your primary focus is fine or sensitive powders: An electromagnetic shaker is necessary for its precise control over frequency and amplitude, ensuring gentle yet complete separation.

- If your primary focus is achieving the highest accuracy: You must use an electromagnetic shaker and methodically test different settings to find the optimal balance of motion that separates your specific material without causing attrition.

Ultimately, controlling the shaker's complex motion—not just its speed—is the key to achieving reliable and precise particle size analysis.

Summary Table:

| Factor | Impact on Sieve Shaker Performance |

|---|---|

| Motion Type | Determines particle agitation; 3D orbital motion is most effective for separation. |

| Drive Type | Electromagnetic drives offer precise control; mechanical drives are more robust. |

| Material Type | Fine powders and coarse aggregates require different frequency and amplitude settings. |

| Goal | High accuracy demands fine-tuned settings to prevent particle attrition or incomplete separation. |

Achieve precise and reliable particle size analysis with the right equipment.

Selecting the correct sieve shaker and settings is critical for your lab's accuracy and efficiency. KINTEK specializes in high-quality lab equipment, including advanced electromagnetic sieve shakers that provide the precise control needed for your specific materials—from fine powders to coarse aggregates.

Let our experts help you optimize your particle sizing workflow. Contact KINTEK today to find the perfect sieve shaker for your laboratory's needs.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

People Also Ask

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- What is the significance of using a fine sieving system for catalyst particles? Optimize Size for Maximum Reactivity

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- What function does a sieving system perform during HPS powder pretreatment? Ensure Uniform Particle Size Distribution

- Why is a precision vibratory sieving system important for Pt/Pd alloy analysis? Ensure Data Integrity & XRD Accuracy