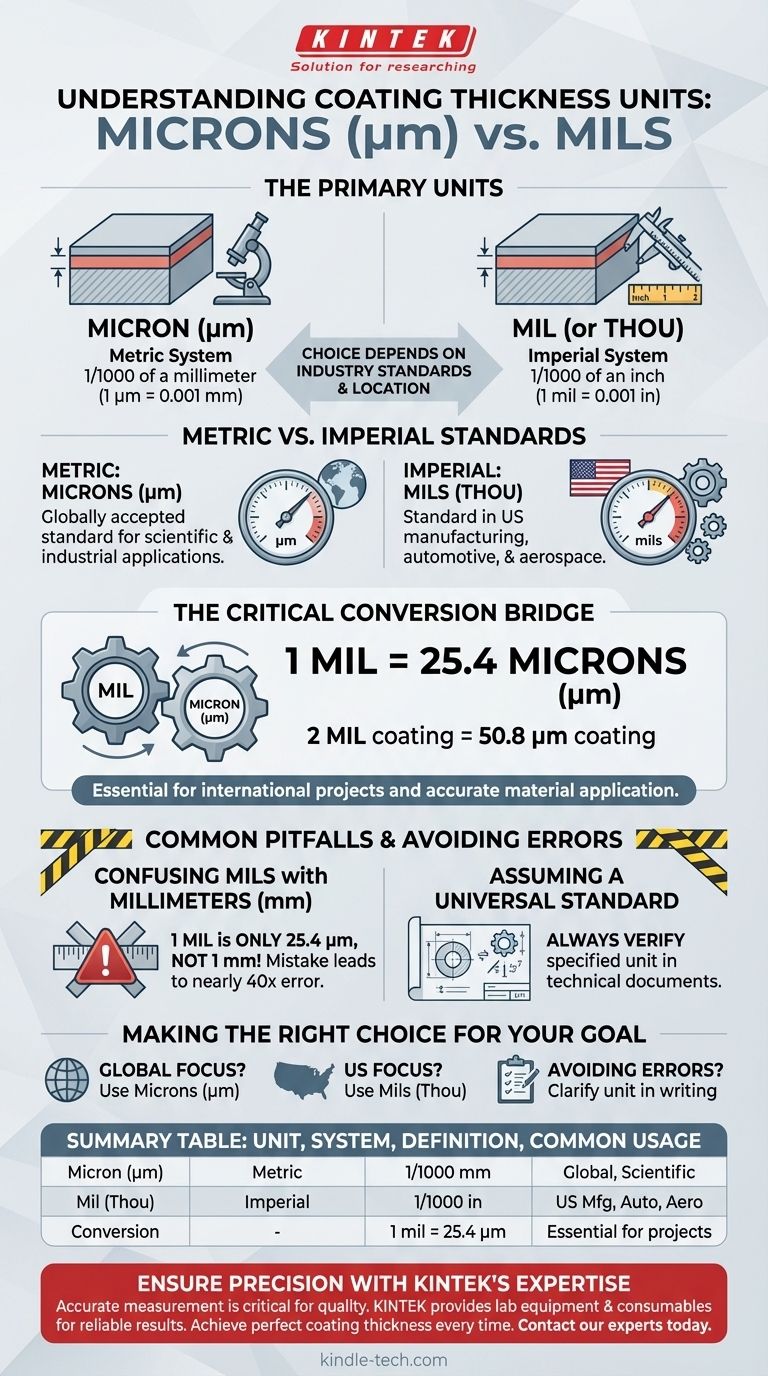

The primary units for coating thickness are the micron (µm) in the metric system and the mil (or thou) in the imperial system. A micron is one-thousandth of a millimeter (1/1000 mm), while a mil is one-thousandth of an inch (1/1000 in). The choice between them is dictated by industry standards and geographic location.

Understanding the distinction between metric and imperial units for coating thickness is not just a matter of preference; it is a critical requirement for meeting specifications, ensuring quality control, and preventing costly manufacturing errors.

The Two Primary Measurement Systems

To accurately measure and specify coating thickness, you must be fluent in the two dominant systems of measurement. Each is prevalent in different parts of the world and in different industries.

The Metric Standard: Microns (µm)

The micron (µm), also known as a micrometer, is the globally accepted standard for most scientific and industrial applications.

It is defined as one-thousandth of a millimeter. To put this in perspective, 1000 microns equal just 1 millimeter, highlighting the fine scale of these measurements.

The Imperial Standard: Mils (or Thou)

In the United States, the mil is the standard unit for coating thickness. The term is often used interchangeably with thou, which is short for one-thousandth of an inch.

One mil is equivalent to 1/1000th of an inch. This unit is deeply embedded in American manufacturing, automotive, and aerospace specifications.

Why Accurate Conversion is Critical

Projects often involve international teams or adherence to specifications written in a different system than the one you use daily. This makes the ability to convert between units an essential skill.

The Key Conversion Factor

The fundamental relationship between the two units is straightforward and essential to memorize.

1 mil = 25.4 microns (µm)

Therefore, a 2 mil coating is equivalent to a 50.8 µm coating. This conversion is the bridge between the two systems.

Context is Everything

A product specification might call for a 75 µm coating thickness, but your digital gauge might be set to read in mils. Without a correct conversion, you might incorrectly measure the thickness as approximately 3 mils and approve a product that meets the standard.

Conversely, failing to convert could lead you to apply an incorrect amount of material, leading to product failure or wasted resources.

Common Pitfalls to Avoid

The most significant risk in measuring coating thickness is simple human error, often stemming from confusion between units.

Confusing "Mils" with "Millimeters"

A common and costly mistake for newcomers is confusing "mil" with "millimeter" (mm). As we've seen, 1000µm equals 1mm.

Since 1 mil is only 25.4µm, it is a tiny fraction of a millimeter. Mistaking one for the other will result in an error of nearly 40 times the intended thickness, leading to catastrophic part failure.

Assuming a Universal Standard

Never assume which unit is being used. A technical drawing from a European firm will almost certainly use microns, while one from an American company will likely use mils. Always verify the unit specified.

Making the Right Choice for Your Goal

Your choice of unit is determined by the requirements of your project, your client, and your industry.

- If your primary focus is working to international or scientific specifications: You should use microns (µm) as it is the globally recognized standard.

- If your primary focus is a project based in the United States: You should use mils (thou), but always be prepared to convert for international partners or when using imported materials.

- If your primary focus is avoiding costly errors: Always clarify the required unit of measurement in writing before beginning any coating work.

Ultimately, precision in your measurements and clarity in your communication are paramount to success.

Summary Table:

| Unit | System | Definition | Common Usage |

|---|---|---|---|

| Micron (µm) | Metric | 1/1000 of a millimeter | Global standard, scientific applications |

| Mil (Thou) | Imperial | 1/1000 of an inch | US manufacturing, automotive, aerospace |

| Conversion | - | 1 mil = 25.4 microns | Essential for international projects |

Ensure precision in your coating processes with KINTEK's expertise.

Accurate coating thickness measurement is critical for product quality and compliance. Whether you're working with microns or mils, KINTEK provides the lab equipment and consumables you need for reliable, repeatable results. Our solutions help laboratories in manufacturing, automotive, and aerospace sectors avoid costly errors and meet international standards.

Let us help you achieve perfect coating thickness every time. Contact our experts today to discuss your specific requirements and discover how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

- Shaking Incubators for Diverse Laboratory Applications

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

People Also Ask

- What are the advantages of using PTFE molds for epoxy resin flame retardant samples? Ensure High-Purity Material Testing

- What is the function of PTFE O-rings in cellulose acid hydrolysis? Ensure Leak-Proof Reactor Sealing at 250°C

- Why are Polytetrafluoroethylene (PTFE) molds preferred for UV-cured siloxane films? Ensure Damage-Free Sample Release

- What are the advantages of using PTFE jars for RuTi alloy mixing? Ensure Chemical Purity and High Yield

- Why is a PTFE casing used in liquid tin stability experiments? Achieve Superior Thermal Isolation and Precision