At its core, a colloidal mill is a high-performance machine designed for particle size reduction and dispersion within a liquid. Its primary use is to finely shear, grind, and homogenize materials to create extremely stable emulsions, suspensions, and colloidal solutions. This process ensures that solids are broken down and evenly distributed within a liquid, or that immiscible liquids (like oil and water) are blended into a stable, non-separating mixture.

The crucial function of a colloidal mill is not just to mix, but to apply intense mechanical shear force. This force breaks down particles and droplets to the micron or sub-micron level, which is essential for the texture, stability, and performance of countless products in the food, pharmaceutical, and chemical industries.

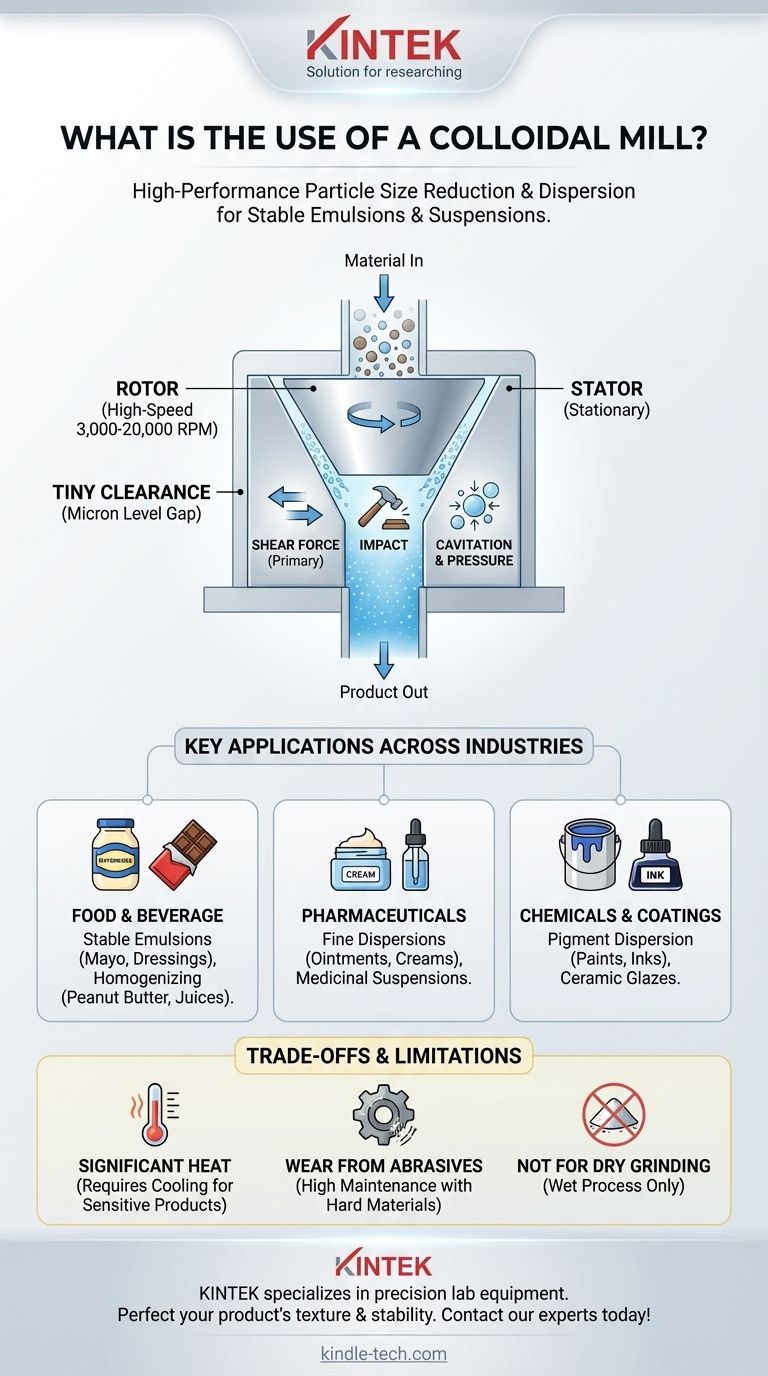

How a Colloidal Mill Achieves Its Results

A colloidal mill's effectiveness comes from its precise engineering, which is designed to subject materials to extreme physical forces in a controlled manner.

The Rotor-Stator Mechanism

The heart of the mill consists of two main parts: a high-speed rotating cone called the rotor and a stationary cone called the stator.

The rotor spins at very high RPM (typically 3,000 to 20,000 RPM) within the stator. The clearance between the two surfaces is extremely small and often adjustable, usually measured in thousandths of an inch.

The Power of High Shear

Material is fed into the gap between the rotor and stator. As the rotor spins, it creates a powerful centrifugal force that pushes the material through the tiny clearance at very high velocity.

This action creates intense mechanical shear, which is the primary force responsible for breaking down particles and droplets.

The Forces at Play

The size reduction is a result of several combined forces inside the mill:

- Shear: The primary action, where the high-velocity difference between the rotor and stator surfaces effectively tears particles apart.

- Impact: Particles are subjected to high-frequency impacts against the surfaces of the rotor and stator teeth or grooves.

- Hydraulic Pressure & Cavitation: The intense liquid pressure and the formation and collapse of microscopic bubbles (cavitation) create powerful shockwaves that further contribute to breaking down the material.

Key Applications Across Industries

The ability to create fine, stable mixtures makes the colloidal mill indispensable in a wide range of applications.

Creating Stable Emulsions

For products that mix oil and water, the mill is essential. It breaks down fat or oil droplets to such a small size that they remain suspended indefinitely.

Examples include mayonnaise, salad dressings, creams, lotions, and pharmaceutical ointments.

Producing Fine Dispersions

The mill excels at breaking down clumps of solid particles (agglomerates) and distributing them uniformly throughout a liquid base.

This is critical for products like paints, inks, pigments, ceramic glazes, and medicinal suspensions.

Homogenizing and Grinding

It is also used to create smooth, consistent textures in viscous products by grinding and blending the components simultaneously.

Common applications include manufacturing peanut butter, chocolate, fruit juices, and various chemical pastes.

Understanding the Trade-offs and Limitations

While powerful, a colloidal mill is not a universal solution. Understanding its limitations is key to using it effectively.

Not a Primary Grinder

A colloidal mill is a "wet grinder" designed for reducing the size of particles already in a liquid suspension. It is not suitable for dry grinding or for breaking down large, hard solids from scratch. Many processes require pre-milling solids before they are introduced to the colloidal mill.

Significant Heat Generation

The intense friction within the mill generates a substantial amount of heat. For heat-sensitive products like some pharmaceuticals or food items, this can be a problem. Many mills are equipped with a cooling jacket to manage the temperature.

Wear from Abrasive Materials

Processing highly abrasive materials (like hard mineral pigments) can cause rapid wear on the rotor and stator. This increases maintenance costs and can introduce contaminants into the product if not managed properly.

Throughput vs. Fineness

There is a direct trade-off between the output rate (throughput) and the fineness of the product. A smaller gap between the rotor and stator produces finer particles but restricts the flow, reducing the overall output.

Making the Right Choice for Your Process

Selecting the correct equipment depends entirely on your final product goals. A colloidal mill is a specialized tool, not a simple mixer.

- If your primary focus is creating stable emulsions like sauces or lotions: A colloidal mill is an excellent choice due to its intense shearing that prevents separation.

- If your primary focus is dispersing pre-milled solids into a liquid for products like paints or inks: The mill is ideal for ensuring a uniform, agglomerate-free mixture.

- If your primary focus is achieving the absolute finest particle size (<1 micron) for advanced applications: You may need to consider a high-pressure homogenizer, which uses a different mechanism to achieve even smaller particle sizes.

- If your primary focus is simply blending liquids or solids that mix easily: A standard agitator or ribbon blender is a far more efficient and cost-effective solution.

Ultimately, a colloidal mill is the right tool when the physical stability and texture of your final product depend on reducing particles to a fine, uniform size within a liquid.

Summary Table:

| Feature | Key Function | Common Applications |

|---|---|---|

| High-Shear Grinding | Reduces particle/droplet size to micron/sub-micron level | Mayonnaise, lotions, ointments |

| Rotor-Stator Mechanism | Applies intense mechanical shear, impact, and cavitation | Paints, inks, pigments, suspensions |

| Homogenization | Creates uniform, stable mixtures and smooth textures | Peanut butter, chocolate, fruit juices |

| Limitations | Generates heat; not for dry grinding or large solids | Requires cooling for heat-sensitive products |

Ready to perfect your product's texture and stability?

KINTEK specializes in precision lab equipment, including colloidal mills, to help you achieve superior emulsions and dispersions. Whether you're developing a new pharmaceutical ointment, a smoother food paste, or a more stable chemical suspension, our expertise ensures you get the right equipment for your specific needs.

Contact our experts today to discuss how we can support your laboratory's success!

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Jar Mill with Agate Grinding Jar and Balls

- Laboratory Micro Tissue Grinding Mill Grinder

- Laboratory Four-Body Horizontal Jar Mill

People Also Ask

- What role does a high-energy ball mill play in the preparation of CNT/Al composites? Achieving Superior Matrix Dispersion

- What is a colloidal mill also known as? Discover the Power of Rotor-Stator Mixers

- What is the use of grinding in laboratory? Unlock Accurate & Homogeneous Sample Analysis

- How does a high-energy ball mill facilitate solid-solution alloying? Unlock Advanced HEA Synthesis Techniques

- What is the role of a V-type mixer in the preparation of Ti-Cr3C2 composite powders? Ensuring Macroscopic Uniformity

- What is the purpose of performing secondary grinding with a ball mill on annealed LAGP glass? Boost Sintering Results

- What is the primary function of mechanical grinding equipment in PHBV production? Optimize Feedstock for Maximum Yield

- What are the disadvantages of roller mills? Key Limitations in Particle Size and Material Handling