In a laboratory setting, grinding is the fundamental process of breaking down a solid material into smaller, more uniform pieces. This is achieved using a grinding mill that applies mechanical force to overcome the material's internal bonds, altering its particle size, shape, and distribution. It is used on an exceptionally wide range of materials, from hard minerals and pharmaceuticals to soft plant tissues and fibrous foods.

The core purpose of grinding is not just to make things smaller; it is to prepare a sample for accurate and repeatable analysis. By creating a fine, homogeneous powder, you ensure that any small portion taken for measurement is truly representative of the entire original sample.

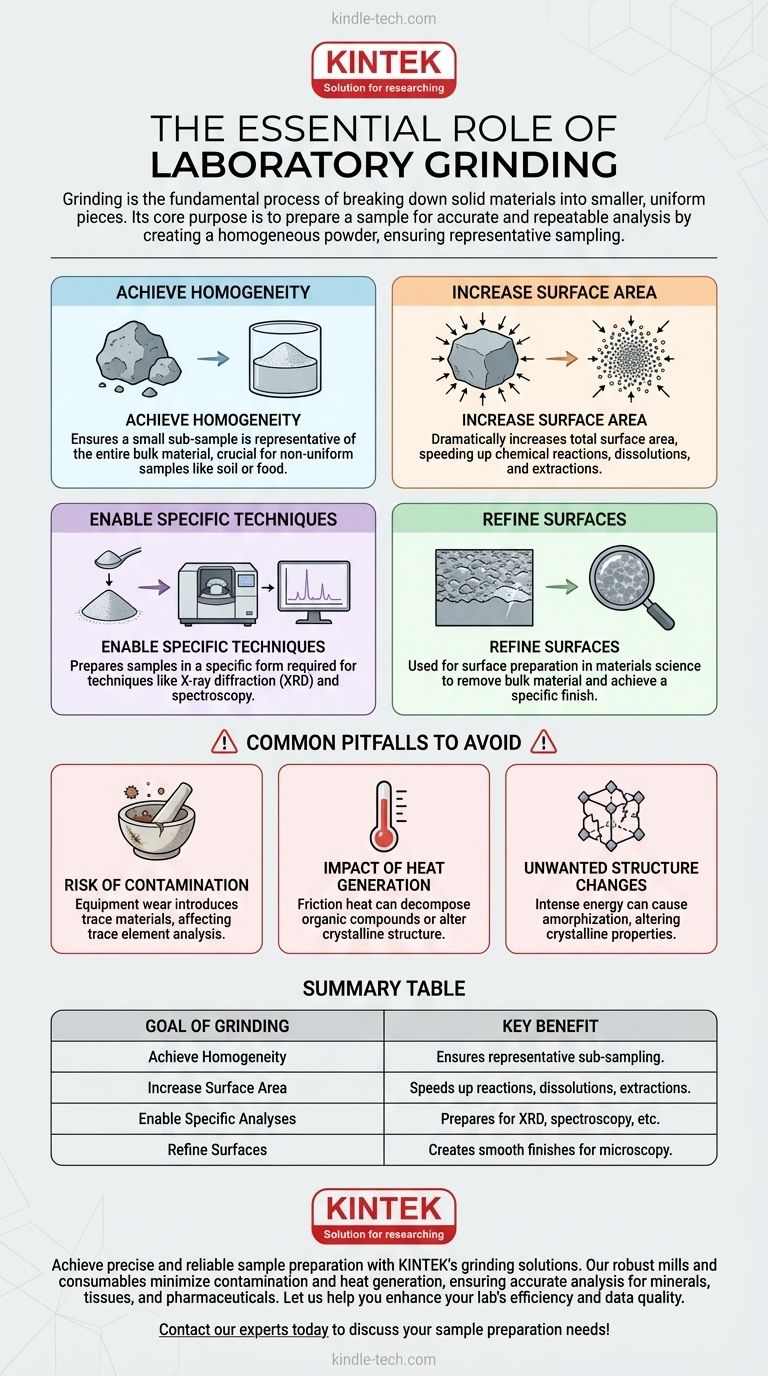

The Primary Goals of Laboratory Grinding

Grinding is a critical preparatory step that directly enables or enhances the quality of subsequent analysis. The specific goal depends on the material and the intended experiment.

Achieving Sample Homogeneity

Many samples, from soil to food products, are inherently non-uniform. Grabbing a small piece for testing would not accurately reflect the whole.

Grinding and mixing the entire bulk sample into a fine powder creates a homogeneous mixture. This ensures that any sub-sample taken for analysis has the same composition as the original, which is essential for reliable and reproducible results.

Increasing Reaction Surface Area

Chemical reactions, dissolution, and extractions occur at the surface of a material. A large, solid chunk has a relatively small surface area for its mass.

By grinding that same chunk into a fine powder, you dramatically increase the total surface area. This allows solvents and reactants to access more of the material simultaneously, leading to faster and more complete reactions or extractions.

Enabling Specific Analytical Techniques

Many modern analytical instruments require samples to be in a specific physical form to function correctly.

Techniques like X-ray diffraction (XRD) and certain types of spectroscopy require a fine, uniform powder to produce a clear signal. Improper sample preparation can lead to inaccurate or uninterpretable data.

Refining Surfaces for Examination

In fields like materials science and metallurgy, grinding is used for a different purpose: surface preparation.

It is used to remove bulk material, smooth a surface, and achieve a specific finish. This is a critical step before examining a material's microstructure under a microscope.

Common Pitfalls to Avoid

While essential, the grinding process itself can introduce errors if not managed carefully. Understanding these trade-offs is key to generating trustworthy data.

The Risk of Contamination

The grinding equipment (bowls, balls, or blades) can wear down during operation. This can introduce trace amounts of the equipment's material (e.g., steel, tungsten carbide, agate) into your sample.

This cross-contamination is a major concern, especially when performing trace element analysis where even tiny impurities can skew results.

The Impact of Heat Generation

The friction involved in milling generates significant heat. This can be problematic for heat-sensitive samples.

Excessive heat can cause organic compounds to decompose, volatile components to evaporate, or a material's crystalline structure to change. This alters the sample from its original state, leading to incorrect analytical conclusions.

Unwanted Changes to Material Structure

The intense mechanical energy of grinding can do more than just reduce particle size.

For some crystalline materials, the process can damage the crystal lattice, a phenomenon known as amorphization. If your goal is to study the material's crystalline structure, this is an undesirable artifact that must be controlled.

Making the Right Choice for Your Goal

The "correct" way to grind a sample depends entirely on your ultimate objective.

- If your primary focus is accurate chemical analysis: Your goal is to create a perfectly homogeneous powder so that any sub-sample you take is identical to the bulk material.

- If your primary focus is accelerating a reaction or extraction: Your goal is to maximize surface area by grinding the material as finely and uniformly as possible.

- If your primary focus is studying a material's crystal structure: Your goal is to reduce particle size with the minimum possible energy to avoid altering the crystalline properties.

Ultimately, mastering laboratory grinding is about precisely controlling a sample's physical properties to unlock accurate and meaningful data.

Summary Table:

| Goal of Grinding | Key Benefit |

|---|---|

| Achieve Homogeneity | Ensures a small sub-sample is representative of the entire bulk material. |

| Increase Surface Area | Speeds up chemical reactions, dissolutions, and extractions. |

| Enable Specific Analyses | Prepares samples for techniques like XRD and spectroscopy. |

| Refine Surfaces | Creates smooth finishes for microscopic examination in materials science. |

Achieve precise and reliable sample preparation with KINTEK's grinding solutions.

As a specialist in laboratory equipment, KINTEK provides robust mills and consumables designed to minimize contamination and heat generation, ensuring your samples are prepared accurately for analysis. Whether you're processing hard minerals, soft tissues, or pharmaceuticals, our products help you achieve the homogeneity and particle size required for your specific application.

Let us help you enhance your lab's efficiency and data quality. Contact our experts today to discuss your sample preparation needs!

Visual Guide

Related Products

- Mini Planetary Ball Mill Machine for Laboratory Milling

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Laboratory Test Sieves and Sieving Machines

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- What is the function of a planetary ball mill in MAX phase powder preparation? Unlock High-Purity Atomic Homogeneity

- How are planetary ball mills used for Li2ZrCl6 electrolytes? Achieve High-Conductivity Metastable Phases

- What is the primary function of a planetary ball mill for Fe-Cu composites? Optimize Particle Distribution & Conductivity

- What role does a planetary ball mill play in SHS? Optimize Powder Activation for Superior Alloy Synthesis

- What are the unique energy transfer characteristics of PBM? Master Complex Heterocyclic Synthesis