In essence, an internal mixer is a highly specialized, industrial machine designed to mix and plasticize polymer materials, primarily rubber and plastics. It performs this function intermittently within a fully enclosed chamber, allowing for precise control over temperature and pressure to ensure a consistent, high-quality compound.

The internal mixer's true value lies not just in its ability to mix, but in its function as a closed, controlled system. It solves the core manufacturing challenges of inefficiency, material inconsistency, and worker safety that are inherent in older, open mixing methods.

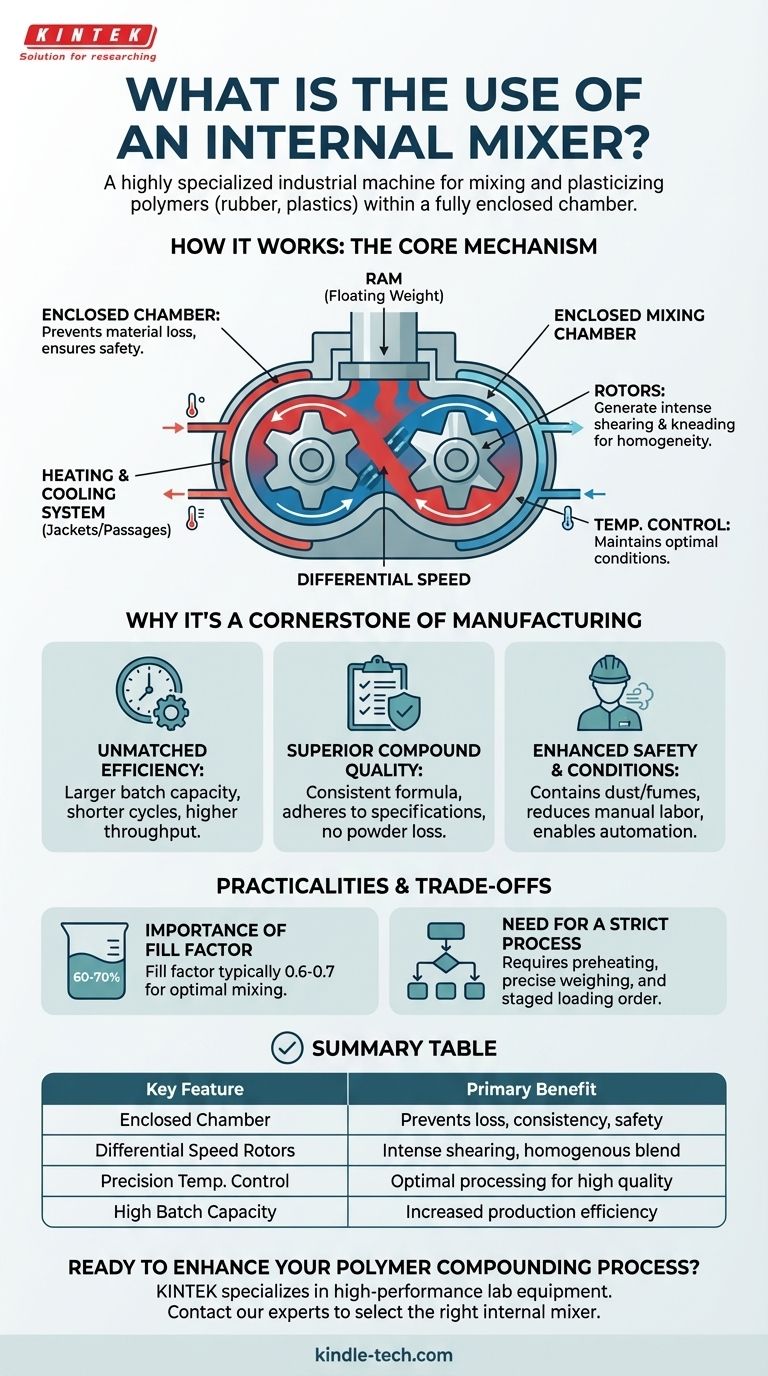

How an Internal Mixer Works: The Core Mechanism

To understand its use, you must first understand its design. An internal mixer is an integrated system where several key components work in concert to achieve a homogenous material blend.

The Enclosed Mixing Chamber

The heart of the machine is the mixing chamber. This is a robust, sealed cavity, often constructed in a figure-eight shape to accommodate the rotors.

A hydraulic or pneumatic ram, often called the upper bolt or floating weight, descends into the chamber after loading. This ram applies pressure, ensuring materials are forced into the mixing zone between the rotors.

The Role of the Rotors

Inside the chamber, two specialized rotors rotate towards each other at slightly different speeds. This differential speed is critical, as it generates the intense shearing and kneading action required to break down, disperse, and homogenize the ingredients.

The geometry of these rotors can be changed. Different rotor designs are selected based on the specific material and the desired outcome, whether it's aggressive plasticizing of raw rubber or gentle blending of a final compound.

Precision Temperature Control

Effective polymer mixing is highly dependent on temperature. The internal mixer controls this with a heating and cooling system.

Jackets surrounding the mixing chamber and passages within the rotors allow a fluid (like water or oil) to circulate, either adding or removing heat. Thermocouples embedded in the chamber wall continuously monitor the material's temperature, providing real-time feedback to maintain optimal processing conditions.

Why It's a Cornerstone of Modern Manufacturing

The internal mixer offers significant advantages over traditional open mill mixing, making it a staple in high-performance manufacturing environments.

Unmatched Mixing Efficiency

Compared to open methods, an internal mixer has a much larger batch capacity and dramatically shorter mixing cycles. This translates directly to higher production efficiency and throughput.

Superior Compound Quality

The enclosed design prevents the loss of fine powders and chemical agents into the air, a common issue with open mills. This ensures the final compound adheres strictly to its intended formula, resulting in higher quality and batch-to-batch consistency.

Enhanced Safety and Working Conditions

By containing dust, fumes, and materials, the internal mixer creates a cleaner and safer work environment. It also reduces the need for direct manual manipulation of the material during the mixing cycle, lowering labor intensity and facilitating automated or semi-automated operation.

Understanding the Practicalities and Trade-offs

While powerful, operating an internal mixer effectively requires a disciplined approach and an understanding of its operational principles.

The Importance of the Fill Factor

You cannot simply fill the chamber to its maximum volume. The effectiveness of the mixing action depends on having enough empty space for the material to be folded and moved by the rotors.

This is managed by the fill factor, which is typically between 0.6 and 0.7 (or 60-70% of the chamber's free volume). Calculating the batch size based on this factor is critical for achieving a homogenous mix.

The Need for a Strict Process

Proper use involves more than just loading and starting the machine. A repeatable, high-quality output depends on a strict operational sequence.

This includes preheating the mixer to the target temperature, verifying all systems (air pressure, cooling water), and accurately pre-weighing and staging all raw materials according to the formula for a precise loading order.

Making the Right Choice for Your Goal

Evaluating the internal mixer's role depends on your primary objective.

- If your primary focus is high-volume production: The internal mixer is the industry standard due to its large capacity and short cycle times.

- If your primary focus is material quality and consistency: Its enclosed, highly controlled environment for temperature and pressure is essential for producing high-specification compounds.

- If your primary focus is operator safety and factory automation: The machine's sealed design and potential for automated loading and unloading make it a superior choice over open systems.

Ultimately, the internal mixer is the enabling technology for achieving efficient, repeatable, and high-quality polymer compounding at an industrial scale.

Summary Table:

| Key Feature | Primary Benefit |

|---|---|

| Enclosed Mixing Chamber | Prevents material loss, ensures batch consistency, and improves safety. |

| Differential Speed Rotors | Delivers intense shearing and kneading for a homogenous blend. |

| Precision Temperature Control | Maintains optimal processing conditions for high-quality output. |

| High Batch Capacity | Increases production throughput and efficiency compared to open mills. |

Ready to enhance your polymer compounding process?

KINTEK specializes in high-performance lab equipment and consumables for industrial applications. Our expertise can help you select the right internal mixer to achieve superior mixing efficiency, consistent material quality, and a safer working environment for your laboratory or production facility.

Contact our experts today to discuss your specific needs and discover the KINTEK difference!

Visual Guide

Related Products

- Lab Internal Rubber Mixer Rubber Kneader Machine for Mixing and Kneading

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Oscillating Orbital Shaker

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

People Also Ask

- What products are blown film extrusion? From Grocery Bags to Industrial Sheeting

- What is the meaning of calendering? Achieve Superior Surface Finish and Material Uniformity

- What is the use of a blown film machine? To Produce Strong, Versatile Plastic Films for Packaging

- What is the process of twin screw granulation? Achieve Superior Consistency in Pharmaceutical Manufacturing

- What are the three 3 basic types of mixers? Find Your Perfect Match for Baking & Production

- What is the two roll mill mixing process? Master Polymer Compounding with High Shear

- What is the difference between extrusion coating and extrusion lamination? A Guide to Material Enhancement

- What are natural rubber sheets used for? Unlock Durability, Elasticity, and Vibration Damping