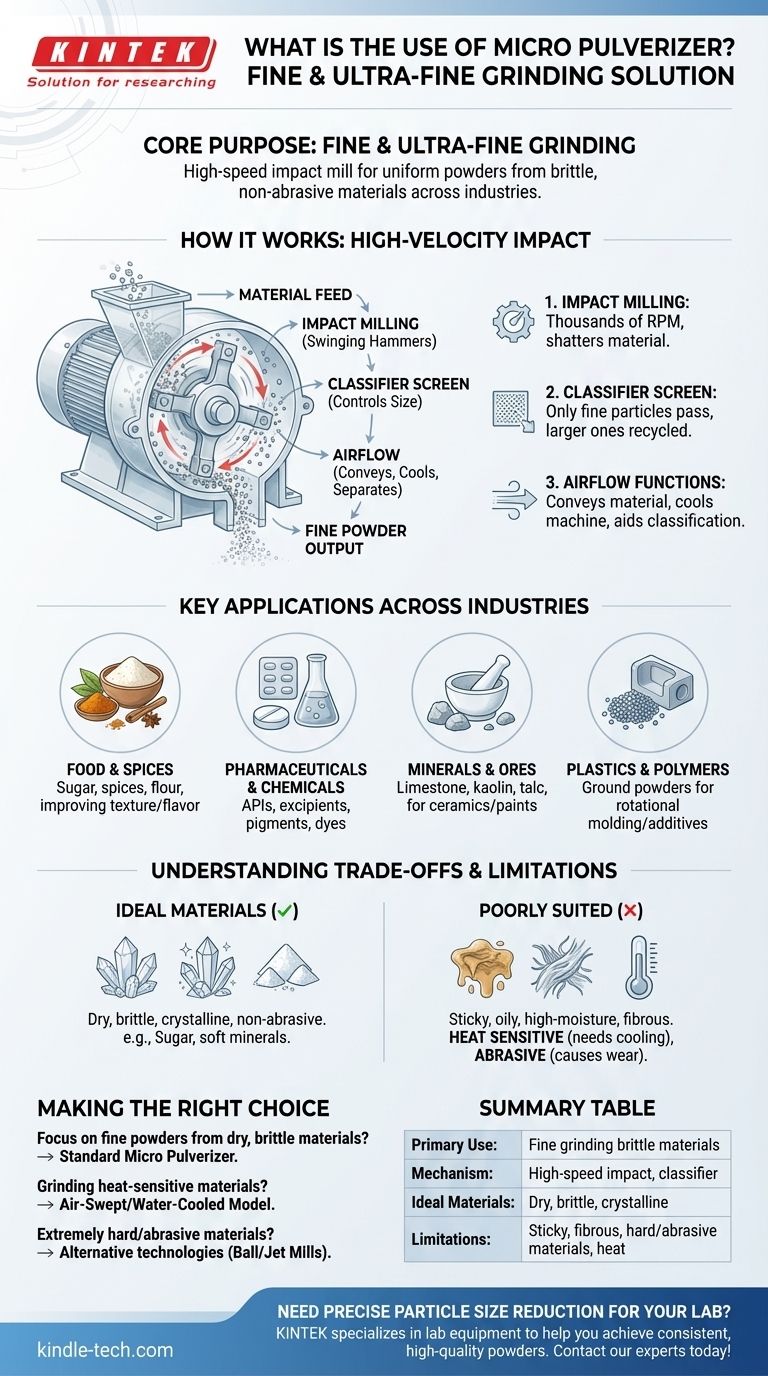

At its core, a micro pulverizer is used for the fine and ultra-fine grinding of a wide range of materials. It is a high-speed impact mill that shatters particles rather than crushing them, making it exceptionally effective for creating uniform powders from brittle, non-abrasive substances across numerous industries.

The central purpose of a micro pulverizer is to achieve precise particle size reduction through high-velocity impact. Its design makes it ideal for materials that are brittle and not overly abrasive, but less suitable for those that are sticky, fibrous, or extremely hard.

How a Micro Pulverizer Achieves Fine Grinding

Understanding the mechanism of a micro pulverizer is key to knowing its ideal applications and limitations. The process is not based on pressure or crushing, but on speed and impact.

The Principle of Impact Milling

A micro pulverizer operates using a set of swinging hammers mounted on a rotor that spins at extremely high speeds (thousands of RPM).

Material is fed into the grinding chamber, where it is struck repeatedly by these fast-moving hammers. This intense impact shatters the material into smaller particles.

The Role of the Classifier Screen

The grinding chamber is lined with a perforated metal screen or a liner with a specific profile. This component acts as a classifier, controlling the final output.

Pulverized particles are thrown against this screen by centrifugal force. Only particles that are small enough to pass through the screen's openings can exit the chamber. Larger particles are retained and continue to be struck by the hammers until they reach the target size.

The Importance of Airflow

Most micro pulverizers utilize a powerful stream of air. This airflow serves three critical functions.

First, it conveys material into and out of the grinding chamber, creating a continuous and efficient process. Second, it helps cool the material and the machine, mitigating heat buildup from the high-speed operation. Finally, it aids in classifying and separating the particles.

Key Applications Across Industries

The ability to produce consistent, fine powders makes the micro pulverizer a vital tool in many sectors.

Food and Spices

This is a primary application. The machine is used for grinding sugar to icing grade, creating fine powders from spices like turmeric and chili, and milling grains and pulses into flour. The goal is to improve texture, solubility, and flavor dispersion.

Pharmaceuticals and Chemicals

In pharmaceuticals, micro pulverizers grind Active Pharmaceutical Ingredients (APIs) and excipients to control dissolution rates and ensure blend uniformity. In the chemical industry, they are used for pigments, dyes, resins, and other materials where particle size affects reactivity or appearance.

Minerals and Ores

The micro pulverizer is effective for softer, non-abrasive minerals. It is commonly used for grinding materials like limestone, kaolin, bentonite, and talc into fine powders for use in ceramics, paints, and fillers.

Plastics and Polymers

Certain plastics can be ground into powders for processes like rotational molding or as additives. The machine efficiently reduces plastic granules into a fine, consistent powder.

Understanding the Trade-offs and Limitations

No single technology is perfect for every task. The effectiveness of a micro pulverizer is highly dependent on the material you are processing.

Material Suitability is Critical

The machine excels with materials that are dry, brittle, crystalline, and non-abrasive. It performs poorly with sticky, oily, or high-moisture content materials, which can clog the screen and grinding chamber. Fibrous materials are also difficult to grind via impact.

The Challenge of Heat Generation

The high-speed impact generates significant heat. This can be a major problem for heat-sensitive materials, such as spices (which can lose essential oils), sugar (which can caramelize), or certain plastics (which can melt). Systems with integrated cooling, like water jackets or cryogenic grinding, are often required for these applications.

Wear on Abrasive Materials

Using a micro pulverizer for hard, abrasive materials like silica, quartz, or carborundum is generally not recommended. These materials will cause rapid wear on the hammers and screens, leading to high maintenance costs, downtime, and inconsistent product quality.

Making the Right Choice for Your Goal

To determine if a micro pulverizer is the correct tool, you must align its capabilities with your material properties and desired final product.

- If your primary focus is producing fine powders (50-300 mesh) from dry, brittle materials like sugar, soft chemicals, or limestone: A standard micro pulverizer is an efficient and highly cost-effective solution.

- If your primary focus is grinding heat-sensitive materials like spices or some polymers: A micro pulverizer equipped with a robust air-swept design or a water-cooling jacket is essential to preserve your product's quality.

- If your primary focus is grinding extremely hard, abrasive minerals or achieving nano-scale particle sizes: You must explore alternative technologies like ball mills for abrasive materials or jet mills for ultra-fine grinding.

Ultimately, selecting the right milling technology depends on a clear understanding of your material and your particle size objective.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Use | Fine & ultra-fine grinding of brittle, non-abrasive materials |

| Mechanism | High-speed impact via swinging hammers and a classifier screen |

| Ideal Materials | Dry, brittle, crystalline substances (e.g., sugar, spices, soft minerals) |

| Key Industries | Food & Spices, Pharmaceuticals, Chemicals, Minerals |

| Limitations | Poor for sticky, fibrous, or very hard/abrasive materials; heat generation can be an issue |

Need Precise Particle Size Reduction for Your Lab?

If you're processing dry, brittle materials like chemicals, pharmaceuticals, or food ingredients, selecting the right grinding equipment is critical for your results. KINTEK specializes in lab equipment, including pulverizing solutions, to help you achieve consistent, high-quality powders.

We can help you:

- Select the right mill for your specific material properties and particle size goals.

- Improve efficiency and consistency in your sample preparation and R&D processes.

- Access reliable equipment backed by expert support.

Let's discuss your application. Contact our experts today to find the optimal grinding solution for your laboratory's needs.

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

- High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the role of laboratory stirring equipment in nZVI preparation? Achieve Stable and Uniform Nano Slurries

- What is the difference between a ball mill and a tumbling mill? A Guide to Grinding Equipment Types

- What is the feed and product size of a ball mill? Achieve Fine to Ultra-Fine Grinding

- What is the ball milling process used for? A Guide to Grinding, Alloying, and Blending Materials

- What are the roles of a vacuum dryer and agate mortar in NZVI treatment? Optimize Your Nanomaterial Reactivity

- What is the role of an industrial dry grinder in the surface modification of 304L stainless steel? Expert Insights

- What is the particle size of XRF sample preparation? Achieve Accurate & Repeatable Results

- What role does a high-shear homogenizer play in ODC catalyst suspensions? Unlock Superior Electrochemical Efficiency