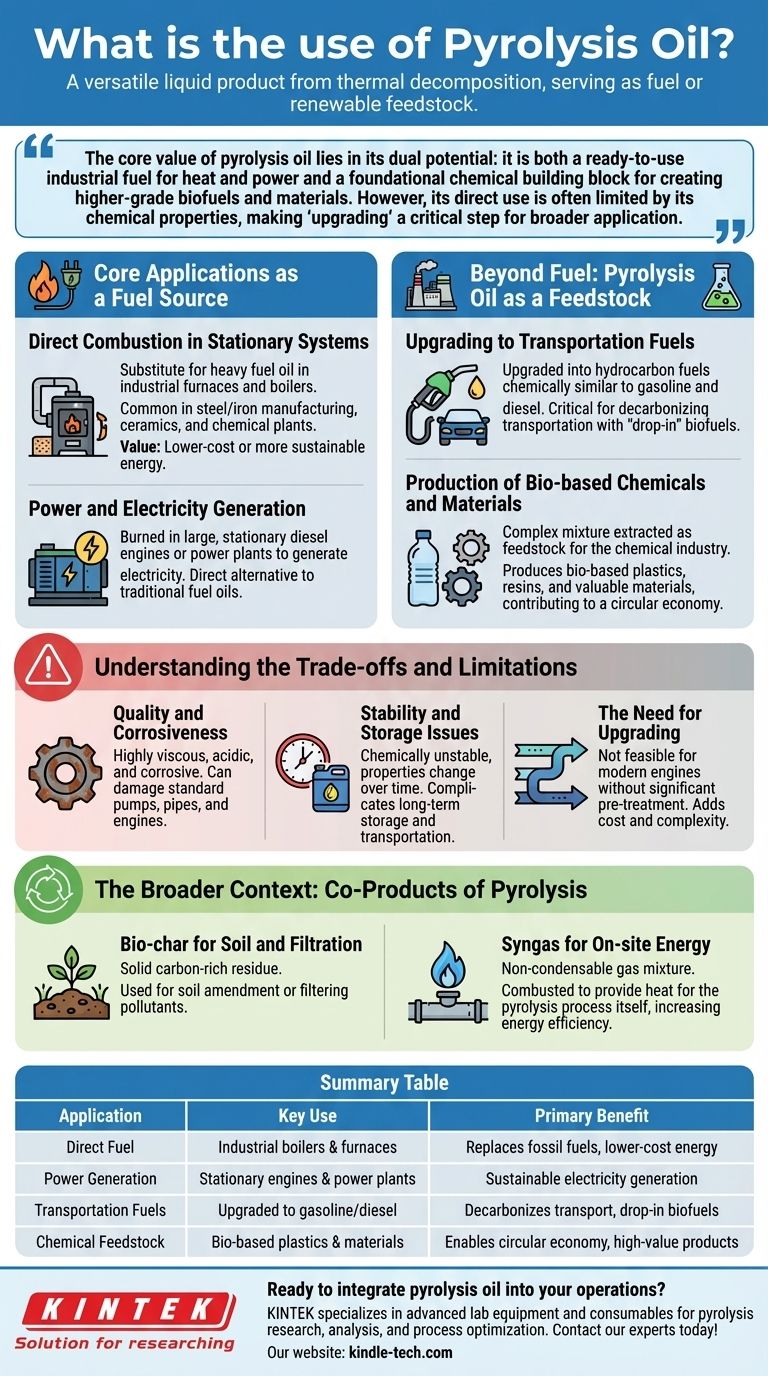

In principle, pyrolysis oil is a versatile liquid product derived from the thermal decomposition of materials like biomass, plastics, or tires in the absence of oxygen. It primarily serves as a direct substitute for conventional fuel oils in stationary applications like industrial boilers, furnaces, and power generation units. It also holds significant potential as a renewable feedstock that can be upgraded into transportation fuels or used to produce valuable chemicals.

The core value of pyrolysis oil lies in its dual potential: it is both a ready-to-use industrial fuel for heat and power and a foundational chemical building block for creating higher-grade biofuels and materials. However, its direct use is often limited by its chemical properties, making "upgrading" a critical step for broader application.

Core Applications as a Fuel Source

The most immediate and common use for pyrolysis oil is as a direct energy source, leveraging its combustible nature as a replacement for fossil fuels.

Direct Combustion in Stationary Systems

Pyrolysis oil can be used as a substitute for heavy fuel oil in industrial furnaces and boilers. This is a common application in industries like steel and iron manufacturing, ceramics, and chemical plants that require significant thermal energy.

Its value here is its potential to be a lower-cost or more sustainable energy source, especially if derived from waste materials.

Power and Electricity Generation

The oil can be burned in large, stationary diesel engines or power plants to generate electricity. This application treats pyrolysis oil as a direct alternative to the fuel oils traditionally used for grid or off-grid power generation.

Beyond Fuel: Pyrolysis Oil as a Feedstock

While direct burning is its simplest application, the greater long-term potential for pyrolysis oil involves using it as a raw material for more refined products.

Upgrading to Transportation Fuels

Through processes in existing refinery infrastructure, pyrolysis oil can be upgraded into hydrocarbon fuels that are chemically similar to gasoline and diesel. This involves treating the oil to improve its stability, remove corrosive elements, and increase its energy density.

This pathway is critical for decarbonizing the transportation sector, as it allows for the creation of "drop-in" biofuels.

Production of Bio-based Chemicals and Materials

Pyrolysis oil is a complex mixture of chemical compounds that can be extracted and used as feedstock for the chemical industry. This allows for the production of bio-based plastics, resins, and other valuable materials, contributing to a circular economy.

Understanding the Trade-offs and Limitations

Despite its potential, raw pyrolysis oil is not a simple drop-in replacement for all fossil fuels. Its widespread industrial adoption is constrained by several technical challenges.

The Challenge of Quality and Corrosiveness

Compared to refined petroleum fuels, pyrolysis oil is often highly viscous, acidic, and corrosive. This can damage standard fuel pumps, pipes, and engines that are not specifically designed or modified to handle it.

Stability and Storage Issues

Pyrolysis oil can be chemically unstable, meaning its properties can change over time, especially when exposed to heat or air. This low stability complicates long-term storage and transportation, requiring more careful management than conventional fuels.

The Need for Upgrading

Because of these issues, using pyrolysis oil in more sensitive applications, such as modern vehicle engines, is not feasible without significant pre-treatment or upgrading. This adds an extra layer of cost and complexity to the process.

The Broader Context: Co-Products of Pyrolysis

It is important to remember that the oil is only one output of the pyrolysis process, which also creates other valuable products.

Bio-char for Soil and Filtration

The solid residue, known as bio-char, is a carbon-rich material. It can be used as a powerful soil amendment to improve fertility and water retention or as an adsorbent for filtering pollutants.

Syngas for On-site Energy

The process also yields a non-condensable gas mixture called syngas. This gas can be combusted on-site to provide the heat needed to run the pyrolysis process itself, making the entire operation more energy-efficient and self-sustaining.

How to Apply This to Your Project

The optimal use of pyrolysis oil depends entirely on your operational capabilities and strategic objectives.

- If your primary focus is immediate, low-cost energy: Use raw pyrolysis oil as a direct substitute for heavy fuel oil in robust industrial boilers or furnaces, provided your equipment can handle its challenging properties.

- If your primary focus is producing high-value products: Invest in upgrading and refining technologies to convert pyrolysis oil into transportation-grade biofuels or specialized bio-based chemicals.

- If your primary focus is waste valorization and sustainability: View the entire pyrolysis system as the solution, utilizing the bio-oil for energy, the bio-char for agriculture, and the syngas for process heat.

Ultimately, pyrolysis oil is best understood not as a simple fuel, but as a foundational component in a more sustainable, circular economy.

Summary Table:

| Application | Key Use | Primary Benefit |

|---|---|---|

| Direct Fuel | Industrial boilers & furnaces | Replaces fossil fuels, lower-cost energy |

| Power Generation | Stationary engines & power plants | Sustainable electricity generation |

| Transportation Fuels | Upgraded to gasoline/diesel | Decarbonizes transport, drop-in biofuels |

| Chemical Feedstock | Bio-based plastics & materials | Enables circular economy, high-value products |

Ready to integrate pyrolysis oil into your operations? KINTEK specializes in advanced lab equipment and consumables for pyrolysis research, analysis, and process optimization. Whether you are developing new biofuels, testing feedstock, or scaling up production, our solutions help you achieve precise, efficient, and sustainable results. Contact our experts today to explore how we can support your laboratory's pyrolysis projects!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Evaporation Boat for Organic Matter

- Graphite Vacuum Continuous Graphitization Furnace

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

People Also Ask

- Is induction more efficient than resistance? Unlock Faster Cooking with Up to 90% Energy Efficiency

- What is the boiling point of THC under a vacuum? A Guide to Safe Distillation

- What is the energy efficiency of pyrolysis? It's a System, Not a Single Number

- What are the environmental issues with diamond mining? Uncover the True Ecological and Human Cost

- Why is a precision drying oven required for TiO2 wet gel? Ensure Structural Integrity & Porosity

- What role does a platform shaker play in biological toxicity assessment? Standardize Your Mine Water Testing Protocols

- What is the purpose of using heat treatment? Tailor Material Properties for Superior Performance

- What is sputtering method? A Guide to Advanced Thin-Film Coating Technology