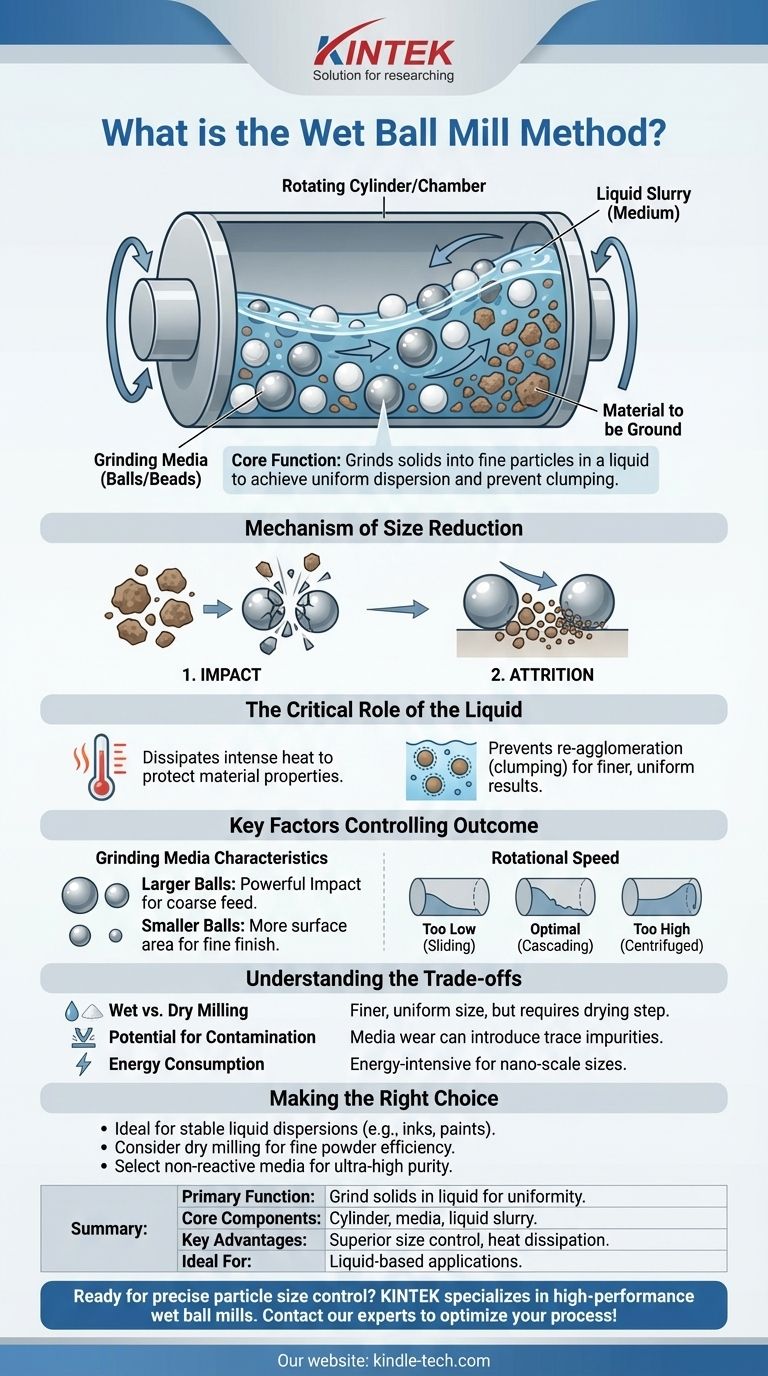

At its core, the wet ball mill method is a mechanical process used to grind solid materials into extremely fine particles within a liquid medium. A rotating cylinder containing hard grinding media, such as ceramic or steel balls, tumbles and collides with the material. This continuous, high-energy impact breaks the material down through repeated fracturing and attrition.

The true purpose of wet milling is not just to reduce particle size, but to achieve a highly uniform and stable dispersion of fine particles within a liquid, preventing the clumping and aggregation common in dry grinding processes.

How the Wet Ball Mill Process Works

The elegance of the ball mill lies in its simple principle, but its effectiveness is determined by the precise interaction of its components. Understanding this mechanism is key to controlling the final product.

The Core Components

A wet ball mill system is built from three primary elements. The first is the hollow cylinder or chamber that contains the entire process.

Inside this chamber is the grinding media—typically spherical balls or beads made of a hard material like steel, zirconium oxide, or ceramic.

Finally, the solid material to be ground is mixed with a liquid to form a slurry. This slurry is the medium in which the entire grinding action takes place.

The Mechanism of Size Reduction

As the cylinder rotates, it lifts the grinding media along the inner wall. At a certain point, gravity overcomes the centrifugal force, and the media cascades back down.

This tumbling action creates two primary grinding forces: impact and attrition. High-energy collisions (impact) shatter larger particles, while the rubbing and shearing action between the balls (attrition) grinds the particles down to a finer state.

The Critical Role of the Liquid

The liquid medium is not passive. It serves to dissipate the intense heat generated during milling, which could otherwise alter the material's properties.

Most importantly, the liquid surrounds each particle, preventing fine powders from re-agglomerating or clumping together. This ensures a more uniform and finer final particle size than is typically achievable with dry milling.

Key Factors Controlling the Outcome

The final particle size and distribution are not accidental. They are the direct result of several controllable variables that must be optimized for each specific application.

Grinding Media Characteristics

The size and material of the grinding balls are paramount. Larger, heavier balls are more effective at breaking down coarse feed materials through powerful impacts.

Smaller balls have more surface area and create more contact points, making them more efficient for achieving a very fine final product once the initial breakdown is complete.

Rotational Speed

The speed of the mill's rotation must be carefully calibrated. If the speed is too low, the balls will simply slide within the chamber, providing little grinding action.

If the speed is too high, centrifugal force will pin the balls and the material to the cylinder wall, halting the tumbling action entirely. The optimal speed creates a continuous, powerful cascade.

Understanding the Trade-offs

While powerful, the wet ball mill method is not a universal solution. Its advantages come with specific considerations that must be weighed against your project's goals.

Wet vs. Dry Milling

Wet milling consistently produces a finer and more uniform particle size. However, it requires a subsequent drying step if the final product needs to be a dry powder, which adds time, energy, and cost to the overall process.

Potential for Contamination

The constant impact and attrition can cause the grinding media itself to wear down over time. This can introduce trace amounts of the media's material into the final product, a critical factor for high-purity applications like pharmaceuticals or electronics.

Energy Consumption

Ball milling is an energy-intensive process. Achieving nano-scale particle sizes can require long milling times, leading to significant operational costs that must be factored into production.

Making the Right Choice for Your Goal

Your decision to use wet milling should be driven by the specific requirements of your end product.

- If your primary focus is creating a stable liquid dispersion (e.g., inks, paints, or slurries): The wet ball mill method is the ideal choice for achieving fine, non-agglomerated particles suspended in a liquid.

- If your primary focus is producing a fine dry powder as efficiently as possible: Consider dry milling first to avoid the added complexity and cost of a post-milling drying process.

- If your primary focus is maintaining ultra-high product purity: You must carefully select non-reactive grinding media and account for potential wear and contamination in your process design.

By understanding these core principles, you can effectively leverage the wet ball mill method to achieve precise particle size control for your specific application.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Function | Grind solid materials into fine particles within a liquid medium to prevent clumping. |

| Core Components | Rotating cylinder, grinding media (balls/beads), and a liquid slurry. |

| Key Advantages | Superior particle size uniformity, effective heat dissipation, and stable dispersions. |

| Ideal For | Applications requiring fine particles in liquid form (e.g., inks, paints, ceramics). |

Ready to achieve precise particle size control for your lab's materials? KINTEK specializes in high-performance lab equipment, including ball mills tailored for wet grinding processes. Whether you're developing inks, coatings, or ceramic slurries, our solutions ensure uniform dispersions and consistent results. Contact our experts today to optimize your milling process!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

- Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

People Also Ask

- What is the ball mill based on the principle of? Impact and Attrition for Efficient Grinding

- How do stainless steel grinding jars and balls contribute to mechanical alloying? Optimize HEA Powder Synthesis

- What are the advantages of polyurethane ball mill jars for silicon nitride? Ensure Purity & Prevent Metal Contamination

- Why are zirconia (ZrO2) milling jars recommended for sulfide electrolytes? Ensure Purity in Li6PS5Cl Synthesis

- Why are excellent sealing and corrosion resistance required for WC-10Co ball milling? Ensure High-Purity Mixing Results