In a ball mill, the grinding components are hard, dense balls, most commonly made from stainless steel. These balls, often referred to as grinding media, are responsible for the size reduction of materials through a combination of high-impact collisions and abrasive attrition. The selection of ball material, size, and quantity is a critical process parameter that directly dictates the efficiency of the grinding and the final particle size of the sample.

The choice of grinding balls is not merely about their material composition; it is a calculated engineering decision. The size, density, and quantity of the media are carefully tailored to the material being processed and the desired outcome to achieve precise particle reduction through controlled impact and friction.

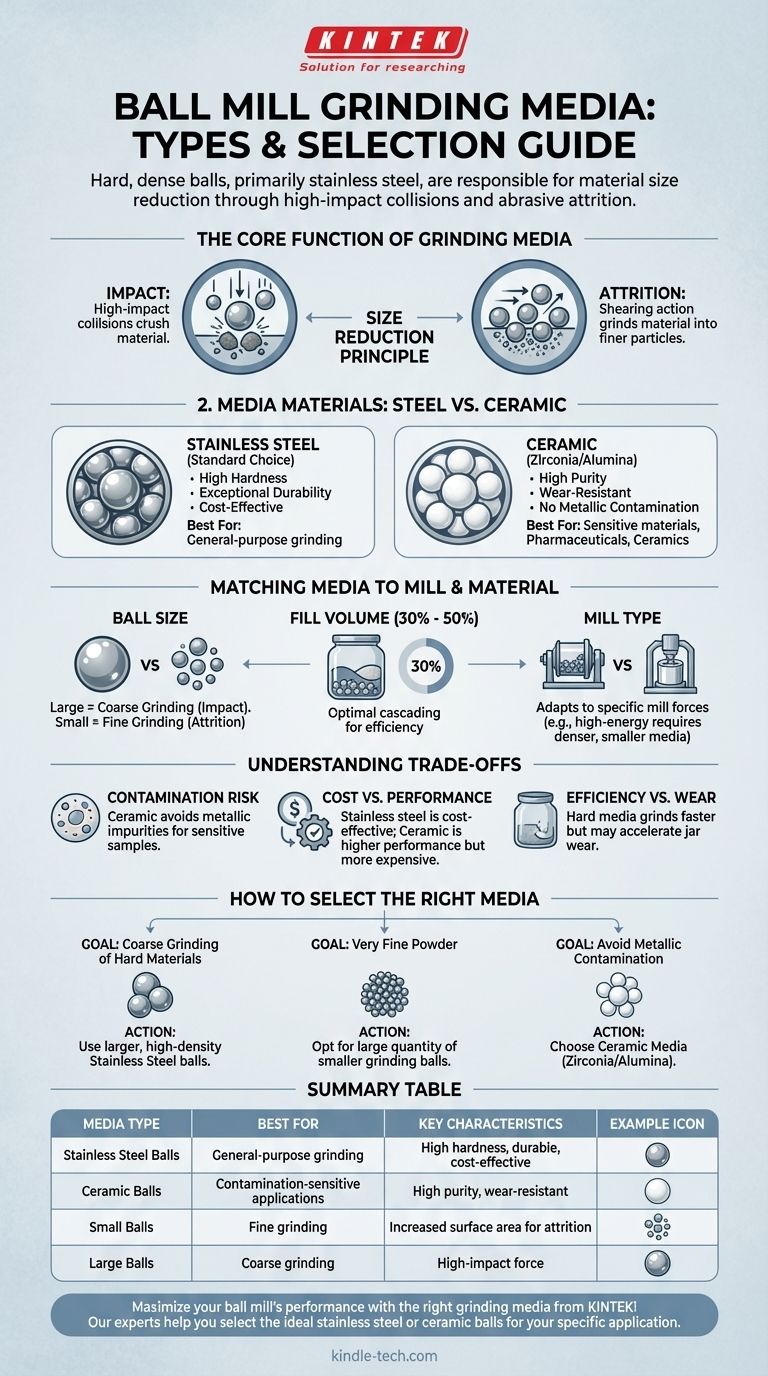

The Core Function of Grinding Media

A ball mill is fundamentally a container filled with a sample and the grinding media. The effectiveness of the entire process depends on the physical characteristics and behavior of these media as the mill operates.

The Principle of Size Reduction

The grinding action inside a ball mill is achieved through two primary mechanisms. Impact occurs when balls fall from the top of the rotating chamber, crushing the material caught between them. Attrition is the shearing action that occurs as balls slide and roll past each other, grinding the material into finer particles.

The Standard Choice: Stainless Steel

Stainless steel is the most common material for grinding balls due to its excellent balance of properties. It offers high hardness for effective grinding, exceptional durability to resist fracturing, and good corrosion resistance, making it suitable for a wide range of applications.

Beyond Steel: Ceramic and Other Media

While steel is a versatile default, it is not the only option. For applications where metallic contamination is a critical concern, ceramic balls made from materials like zirconia or alumina are used. These are extremely hard and wear-resistant, making them ideal for processing ceramics, pigments, and materials for pharmaceutical use.

Matching the Media to the Mill and Material

The type of ball mill and the properties of the material being processed heavily influence the selection of the grinding media. A mismatch can lead to inefficient grinding or even damage to the equipment.

The Critical Factor: Ball Size

The size of the grinding balls is paramount. As a general rule, larger, heavier balls are used for breaking down coarse, large particles through high-impact force. Conversely, a larger quantity of smaller balls provides more surface area and contact points, which is ideal for fine grinding through attrition.

Fill Volume and Efficiency

The effectiveness of the grinding process is highly dependent on the charge volume—the amount of space the balls occupy. Typically, the grinding media should fill between 30% and 50% of the mill's volume. This ratio ensures the balls cascade over one another efficiently, maximizing both impact and attrition without hindering movement.

Adapting to Mill Type

Different mill designs, such as high-energy planetary or vibrating mills, create different forces. These systems often work most efficiently with smaller, denser media that can be rapidly accelerated to generate the intense impact and shearing forces required for rapid size reduction.

Understanding the Trade-offs

Selecting the right grinding media involves balancing performance with practical limitations. Understanding these trade-offs is key to optimizing your process.

Contamination Risk

All grinding media will eventually wear down, introducing trace amounts of their own material into the sample. This is the primary reason for choosing ceramic media when milling sensitive materials where even minute metallic contamination is unacceptable.

Cost vs. Performance

Stainless steel balls offer excellent performance at a moderate cost. However, high-performance ceramic media like zirconia are significantly more expensive. This cost must be justified by the need for higher purity, increased hardness, or better wear resistance.

Grinding Efficiency vs. Wear

Extremely hard media can grind a sample faster, but they may also cause accelerated wear on the milling jar itself, especially if the jar is made of a softer material. The entire system—jar, media, and sample—must be considered together to achieve a sustainable process.

How to Select the Right Grinding Media

Your choice should be directly informed by your specific goal. Use these guidelines to make a decision that aligns with your application's requirements.

- If your primary focus is coarse grinding of hard materials: Use larger, high-density stainless steel balls to maximize the impact force needed to fracture large particles.

- If your primary focus is achieving a very fine powder: Opt for a large quantity of smaller grinding balls to increase the surface area contact and promote efficient attrition.

- If your primary focus is avoiding metallic contamination: Choose ceramic media, such as zirconia or alumina balls, especially when processing sensitive materials or other ceramics.

Ultimately, selecting the correct grinding media is what transforms a ball mill from a simple rotating container into a precise and powerful processing tool.

Summary Table:

| Grinding Media Type | Best For | Key Characteristics |

|---|---|---|

| Stainless Steel Balls | General-purpose grinding | High hardness, durable, cost-effective |

| Ceramic Balls (Zirconia/Alumina) | Contamination-sensitive applications | High purity, wear-resistant, ideal for pharmaceuticals/ceramics |

| Small Balls | Fine grinding | Increased surface area for efficient attrition |

| Large Balls | Coarse grinding | High-impact force for breaking down large particles |

Maximize your ball mill's performance with the right grinding media from KINTEK! Our experts specialize in helping laboratories select the ideal stainless steel or ceramic balls to match your specific material and particle size goals. Whether you're processing hard materials or sensitive samples, KINTEK provides high-quality lab equipment and consumables tailored to your needs. Contact us today to discuss your application and get a personalized recommendation!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Single Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is a laboratory ball mill? A Guide to Precision Grinding for Your Lab

- What is the function of an agate mortar and pestle in mixing LATP powders? Ensure Pure, Homogeneous Synthesis

- How much power does a hammer mill use? From 5HP to 600HP, Key Factors Explained

- What is the role of a mechanical ball mill in the synthesis of glassy inorganic solid electrolytes (ISEs)?

- What is the primary function of a ball mill during the preparation of CuCr50? Master Mechanical Alloying Efficiency

- Why are high-shear strong mixers required for nanoparticles in concrete? Unlock Full Reinforcement Potential

- What is the particle size range of a ball mill? Achieve Precise Grinding from 10 mm to Sub-Micron

- What is the function of vacuum milling in Ti2AlN synthesis? Ensure High Purity & Superior Ceramic Quality