For a hydraulic press, you will almost always use a dedicated hydraulic oil, specifically one with an anti-wear (AW) additive package. The most common viscosity grades for general-purpose presses are ISO VG 32 or ISO VG 46. The single most important factor is to consult your press's user manual, as the manufacturer's recommendation is the definitive guide for your specific equipment.

Choosing the right hydraulic fluid is not about finding a generic product, but about matching the fluid's specific properties—primarily viscosity—to your machine's design and its operating environment. Using the correct oil is one of the most critical steps in protecting your investment and ensuring safe, reliable operation.

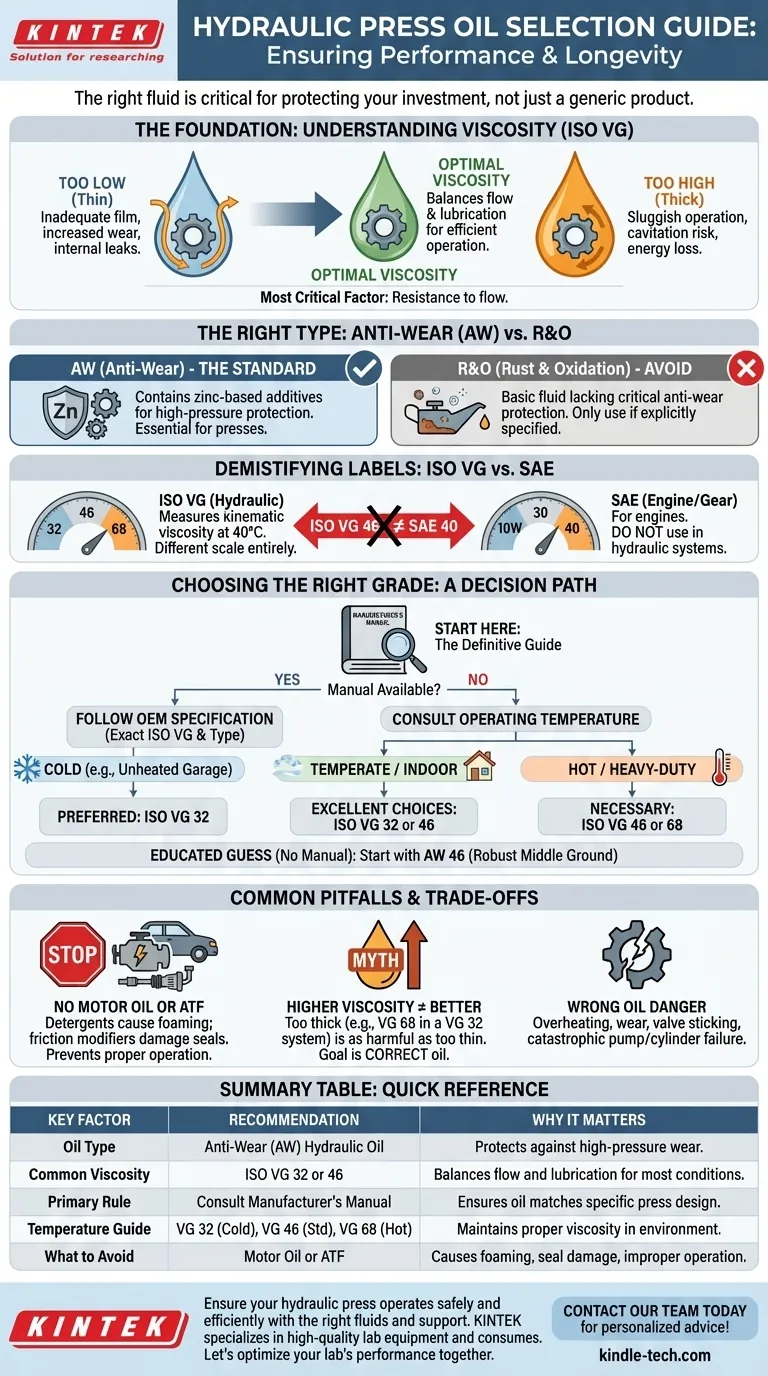

The Foundation: Understanding Hydraulic Oil Properties

To select the correct fluid, you first need to understand what makes one oil different from another. The name on the bottle is less important than the specifications it meets.

Viscosity: The Most Critical Factor

Viscosity is a fluid's resistance to flow. In a hydraulic system, it is the single most important property.

The viscosity, designated by an ISO VG (Viscosity Grade) number, determines the thickness of the oil film that lubricates moving parts and creates seals within pumps and valves.

- Too Low (Too Thin): The oil won't provide an adequate lubricating film, leading to increased wear, internal leaks, and a loss of pressure and efficiency, especially as the system heats up.

- Too High (Too Thick): The oil won't flow easily, especially on a cold start. This can lead to sluggish operation, increased energy consumption, and can starve the pump of fluid, a condition known as cavitation that is highly destructive.

The Role of Additives (AW vs. R&O)

Modern hydraulic fluids are more than just oil; they are a base stock combined with a carefully balanced additive package.

For hydraulic presses, Anti-Wear (AW) oils are the standard. They contain additives (typically zinc-based) that create a sacrificial layer on metal surfaces to protect them under the high-pressure conditions found in hydraulic pumps and valves.

You may also see R&O (Rust & Oxidation Inhibitor) oils. These are a more basic type of hydraulic fluid and generally lack the critical anti-wear protection needed for high-pressure press systems. Always choose an AW oil unless the manufacturer explicitly states otherwise.

Demystifying the Labels: ISO VG vs. SAE

It is critical not to confuse ISO Viscosity Grades with the SAE (Society of Automotive Engineers) grades used for engine or gear oils.

The numbering scales are completely different. An ISO VG 46 hydraulic oil is not the same thickness as an SAE 40 engine oil. Using engine oil in a hydraulic system is a common and costly mistake.

Choosing the Right Viscosity Grade

With an understanding of the properties, you can now select the correct grade for your machine.

Start with the Manufacturer's Manual

This cannot be overstated. The Original Equipment Manufacturer (OEM) designed the pump, valves, and cylinders with a specific fluid viscosity in mind. Their recommendation is based on internal clearances, pump type, and expected operating pressures. The manual is your source of truth.

The Impact of Operating Temperature

If a manual is not available, your primary consideration is the ambient operating temperature.

- Cold Environments (e.g., unheated winter garage): A lower viscosity oil like ISO VG 32 is often preferred. It will flow more easily on startup, ensuring the pump is lubricated immediately.

- Temperate or Indoor Environments: ISO VG 32 or ISO VG 46 are both excellent choices for the majority of shop presses.

- Hot Environments or Heavy-Duty Cycles: For presses that run continuously and generate significant heat, a higher viscosity oil like ISO VG 46 or even ISO VG 68 may be necessary to maintain adequate film strength at elevated temperatures.

Understanding the Trade-offs and Common Pitfalls

Avoiding common mistakes is just as important as selecting the right fluid.

The Danger of Using the Wrong Oil

Using an incorrect fluid can lead directly to overheating, premature wear on the pump, valve sticking, and eventual catastrophic failure. The cost of a new pump or cylinder far outweighs the price of the correct oil.

Can You Use Motor Oil or ATF? No.

This is a frequent and damaging shortcut.

- Motor Oil contains detergents designed to hold contaminants in suspension. In a hydraulic system, these detergents can cause foaming and damage seals.

- Automatic Transmission Fluid (ATF) has friction modifiers designed for clutch packs, which are not present in a standard hydraulic press. These additives provide no benefit and can interfere with proper operation.

The Myth of "Better" Oil

A higher viscosity number is not inherently "better." Using an oil that is too thick (e.g., ISO VG 68 in a system designed for 32) is just as harmful as using one that is too thin. The goal is to use the correct oil, not the thickest one you can find.

Making the Right Choice for Your Press

Follow these guidelines to ensure you select the correct fluid for your application.

- If your primary focus is following best practices: Defer to the manufacturer's manual above all else. Use the exact ISO VG grade and fluid type (AW) they specify.

- If you have a general-purpose press in a standard shop: An AW 32 or AW 46 hydraulic oil will be the correct choice in over 90% of cases.

- If you are operating in extreme temperatures: Adjust your viscosity choice accordingly—lower for cold, higher for hot—but monitor system performance and temperature closely.

- If you have no manual and must make an educated guess: Start with AW 46. It provides a robust middle ground for viscosity and is a very common factory fill for many presses.

Proper fluid selection is the cornerstone of hydraulic system maintenance and will directly contribute to the long and productive life of your equipment.

Summary Table:

| Key Factor | Recommendation | Why It Matters |

|---|---|---|

| Oil Type | Anti-Wear (AW) Hydraulic Oil | Protects pumps and valves from high-pressure wear |

| Common Viscosity (ISO VG) | 32 or 46 | Balances flow and lubrication for most shop conditions |

| Primary Rule | Consult Manufacturer's Manual | Ensures the oil matches your specific press's design |

| Temperature Guide | VG 32 for cold, VG 46 for standard, VG 68 for hot | Maintains proper viscosity under operating conditions |

| What to Avoid | Motor Oil or ATF | Can cause foaming, seal damage, and improper operation |

Ensure your hydraulic press operates safely and efficiently with the right fluids and support. KINTEK specializes in providing high-quality lab equipment and consumables, including reliable hydraulic presses and the correct maintenance supplies for your laboratory needs. Our experts can help you select the perfect equipment and ensure its longevity with proper care guidelines.

Let's optimize your lab's performance together. Contact our team today for personalized advice and solutions!

Visual Guide

Related Products

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

People Also Ask

- What happens if a hydraulic system leaks? Prevent Costly Damage and Safety Hazards

- What is the lifespan of a filter media? Understand the 3 Types for Optimal Filtration

- What is a major cause of hydraulic system and component failures? Prevent Costly Downtime with Clean Fluid

- What are the preventive maintenance of hydraulic systems? Extend Equipment Life and Maximize Uptime

- What are some of the problems related to hydraulic power? Manage Leaks, Contamination, and Inefficiency