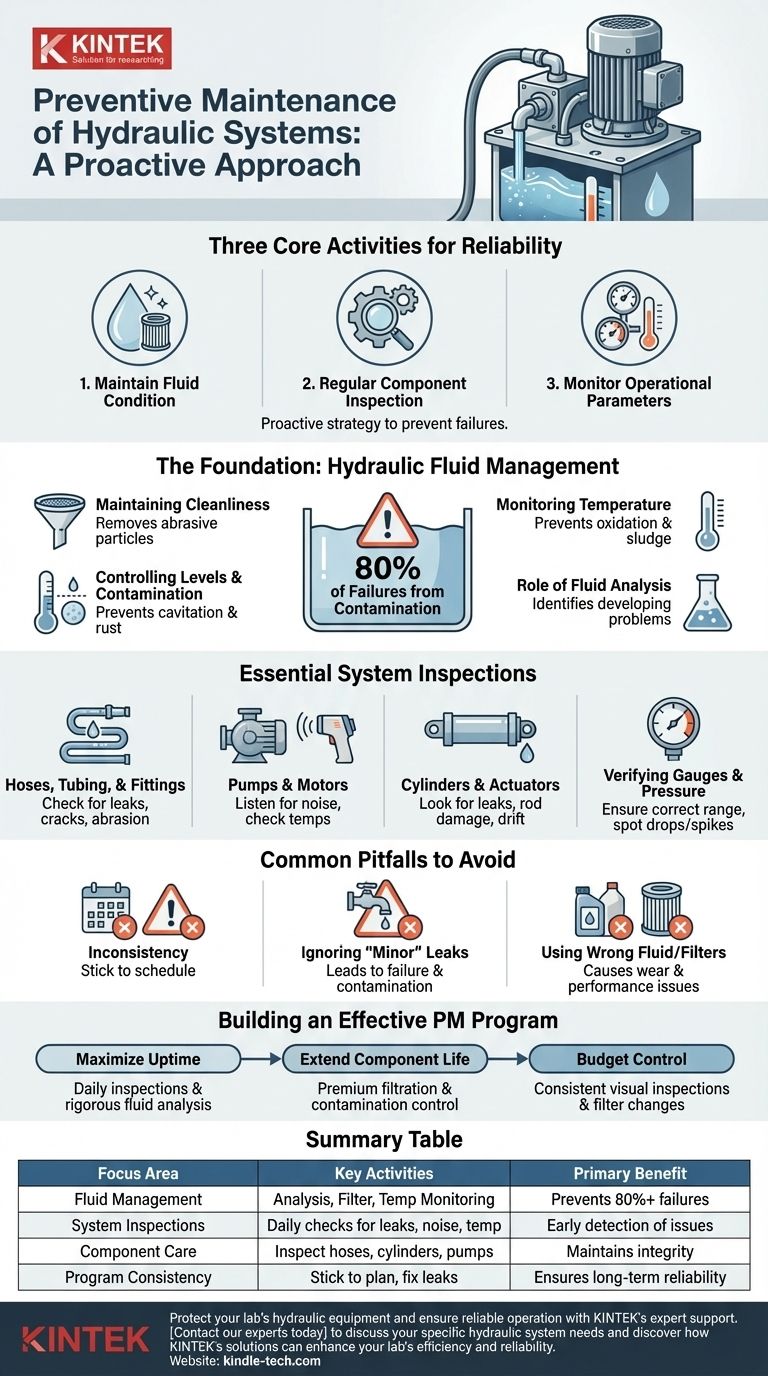

Effective preventive maintenance for hydraulic systems is a scheduled, systematic approach designed to prevent failures before they occur. It centers on three core activities: maintaining the hydraulic fluid's condition, regularly inspecting key components for signs of wear or leakage, and monitoring the system's operational parameters like pressure and temperature. This proactive strategy is the single most important factor in ensuring system reliability and longevity.

The overwhelming majority of hydraulic system failures—often cited as over 80%—are a direct result of contaminated or degraded hydraulic fluid. Therefore, the central focus of any effective preventive maintenance program must be to keep the fluid clean, cool, and free of contaminants.

The Foundation: Hydraulic Fluid Management

The hydraulic fluid is the lifeblood of your system. It transmits power, lubricates components, and dissipates heat. Its condition directly dictates the health and performance of every other component.

Maintaining Fluid Cleanliness

Contaminant particles, even those too small to see, act like a liquid abrasive, grinding away at the tight tolerances inside pumps, valves, and actuators.

An effective filtration system is your primary defense. Regularly scheduled filter element replacements are crucial to remove these harmful particles from the fluid.

Monitoring Fluid Temperature

Excessive heat is a primary enemy of hydraulic fluid. High temperatures cause the fluid to oxidize, forming sludge and varnish that can clog components and cause valves to stick.

Heat also degrades seals and hoses, leading to premature leaks and failures. Ensure heat exchangers and cooling systems are clean and functioning correctly.

Controlling Fluid Levels and Contamination

Low fluid levels can cause the pump to ingest air, leading to a destructive process called cavitation. Always maintain the fluid at the proper level specified by the manufacturer.

It's also critical to prevent water and air from entering the system. Water causes rust and corrosion, while entrained air leads to spongy actuator performance and fluid degradation. Ensure reservoir breathers are functioning and seals are intact.

The Role of Regular Fluid Analysis

Think of fluid analysis as a blood test for your equipment. Sending a small sample of fluid to a lab provides a detailed report on its cleanliness, chemical properties, and the presence of wear metals.

This data allows you to identify developing problems, such as a failing pump bearing or an ineffective filter, long before they cause a catastrophic failure. It is the cornerstone of a predictive, condition-based maintenance strategy.

Essential System Inspections

Daily walk-arounds and scheduled inspections by trained personnel can catch small issues before they become costly breakdowns.

Inspecting Hoses, Tubing, and Fittings

Visually check for any signs of leaks, cracking, abrasion, or blistering on hoses. A leak is not just a housekeeping issue; it's a point where fluid is lost and contamination can enter the system.

Ensure all fittings are secure but not over-tightened, which can damage threads and seals.

Checking Pumps and Motors for Abnormalities

Listen for unusual noises. A high-pitched whining can indicate pump cavitation, while a knocking sound may signal a developing mechanical failure.

Use an infrared temperature gun to check operating temperatures of pumps and motors. A component that is running significantly hotter than normal is a clear warning sign of an impending problem.

Examining Cylinders and Actuators

Look for any fluid leaking from cylinder rod seals, which indicates a seal failure. Check the cylinder rods themselves for scoring or damage that could tear seals.

Also, check for cylinder "drift." If a cylinder slowly moves or fails to hold its position under load, it's a sign of internal leakage past the piston seals.

Verifying Gauges and System Pressure

Gauges are the windows into your system's health. Ensure they are functioning correctly and that system pressures are operating within the specified range during a machine cycle.

An unexpected drop or spike in pressure is a critical diagnostic clue that points to issues like internal leaks, pump wear, or a malfunctioning relief valve.

Common Pitfalls to Avoid

Even with good intentions, maintenance programs can fail if they don't account for common mistakes. Building trust in your program means being aware of potential downsides.

Creating a PM Schedule and Sticking to It

The most common failure is inconsistency. A preventive maintenance plan is only effective if the tasks are performed consistently at their scheduled intervals.

Establish a clear schedule for all inspections, filter changes, and fluid analysis sampling, and ensure it is followed without fail.

Ignoring "Minor" Leaks

A small drip may seem insignificant, but it is a clear indicator of a failing seal, a loose fitting, or a damaged hose.

Furthermore, a point that leaks fluid out under pressure can also draw in contamination when the system is at rest. Addressing all leaks immediately is critical for both safety and contamination control.

Using the Wrong Fluid or Filters

Using a fluid with the wrong viscosity or additive package can cause significant wear and performance issues. Always use the exact fluid type specified by the equipment manufacturer.

Likewise, a filter that doesn't meet the required cleanliness (micron) rating will fail to protect your components, leading to premature failure.

Building an Effective PM Program

Your maintenance strategy should align directly with your operational goals. A well-designed program balances cost, effort, and risk to maximize reliability.

- If your primary focus is maximizing uptime: Prioritize daily operator inspections and a rigorous fluid analysis program to catch developing issues at the earliest possible stage.

- If your primary focus is extending component life: Concentrate relentlessly on contamination control through premium filtration, high-quality breathers, and proper fluid handling procedures.

- If your primary focus is budget control: Start with the highest-return activities, which are consistent visual inspections for leaks and timely replacement of hydraulic filters.

By moving from a reactive to a proactive maintenance philosophy, you gain direct control over your hydraulic system's performance, reliability, and total cost of ownership.

Summary Table:

| Maintenance Focus Area | Key Activities | Primary Benefit |

|---|---|---|

| Hydraulic Fluid Management | Fluid analysis, filter replacement, temperature monitoring | Prevents 80%+ of failures from contamination/oxidation |

| System Inspections | Daily checks for leaks, abnormal noises, temperature spikes | Early detection of wear, leaks, and component issues |

| Component Care | Inspect hoses, cylinders, pumps, and fittings for damage | Maintains system integrity and prevents catastrophic failure |

| Program Consistency | Stick to a scheduled PM plan and address minor leaks immediately | Ensures long-term reliability and cost control |

Protect your lab's hydraulic equipment and ensure reliable operation with KINTEK's expert support.

As a leading provider of laboratory equipment and consumables, KINTEK understands the critical role hydraulic systems play in your lab's productivity. Our team can help you implement a targeted preventive maintenance strategy, including fluid analysis and component inspections, to extend equipment life and minimize costly downtime.

Contact our experts today to discuss your specific hydraulic system needs and discover how KINTEK's solutions can enhance your lab's efficiency and reliability.

Visual Guide

Related Products

- Manual Lab Heat Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

People Also Ask

- Is hydraulic press safe? Ensure Operator Safety with Proper Training and Protocols

- What are some of the problems related to hydraulic power? Manage Leaks, Contamination, and Inefficiency

- What is the Significance of Using a Laboratory Hydraulic Press for Green Compact Pressing? Optimize CNT Composites.

- What is the XRF method of preparation? Ensure Accurate Elemental Analysis with Proper Sample Prep

- How do you press a KBr pellet? Master the FTIR Technique for Clear, Reliable Results

- Why is a high-pressure laboratory hydraulic press required for pelletizing solid-state battery components?

- What are the parts of a hydraulic press machine? A Guide to the Core Systems & Components

- What is the construction of a hydraulic press? The Core Components Explained