While incredibly powerful, hydraulic systems present a distinct set of operational challenges that must be actively managed. The most significant problems are a high susceptibility to contamination, the near-inevitability of fluid leaks, inherent energy inefficiencies that generate waste heat, and the complexity that demands specialized maintenance.

The fundamental challenge of hydraulic power is not that these problems exist, but that they are interconnected. A failure to manage one issue, such as contamination, will directly worsen others, like component wear and heat generation, creating a cascade of potential failures.

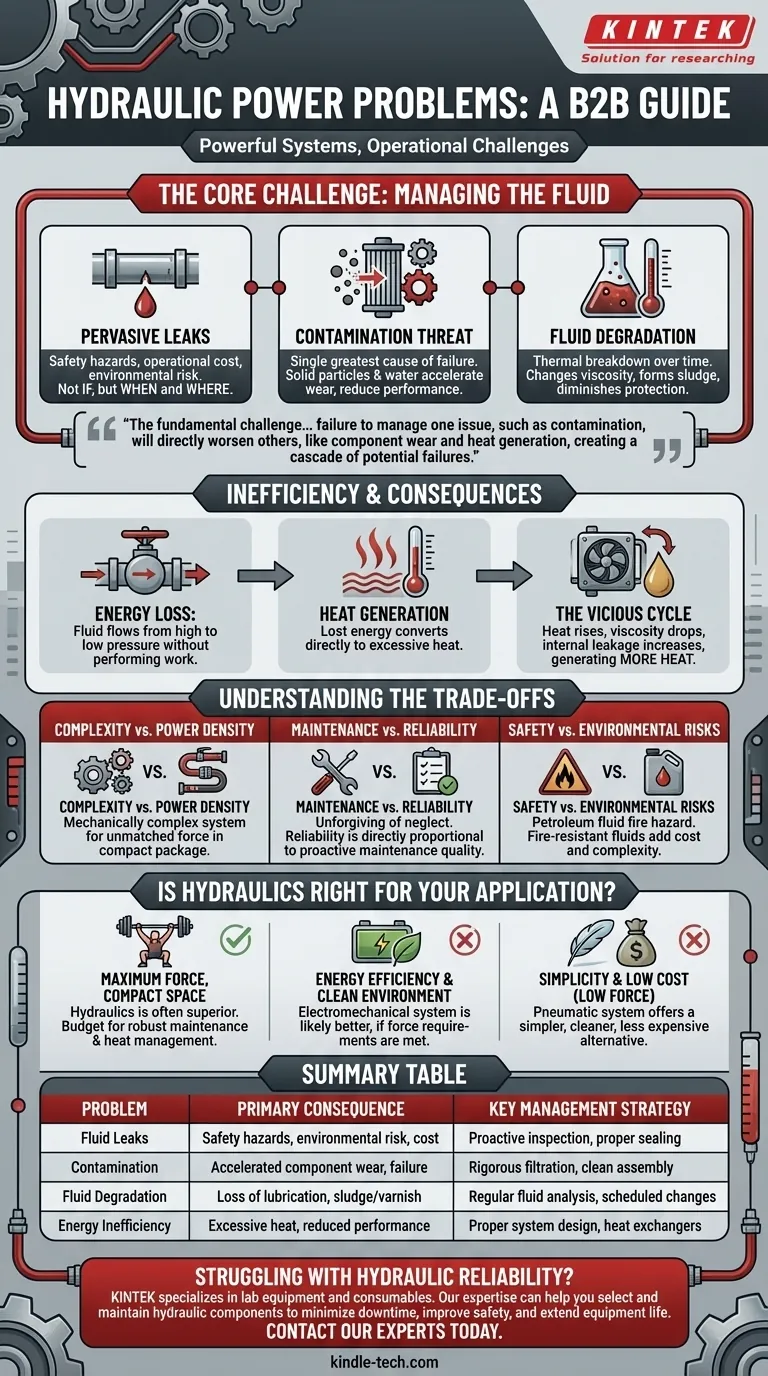

The Core Challenge: Managing the Fluid

At the heart of most hydraulic issues is the fluid itself. It is both the system's lifeblood and its most common point of failure.

The Pervasive Problem of Leaks

A common saying among technicians is, "It's not a matter of if a hydraulic system will leak, but when and where." Leaks, even minor ones, have significant consequences.

They create safety hazards, from simple slips and falls to dangerous high-pressure injection injuries if a pinhole leak pierces the skin. Leaks also represent a direct operational cost in lost fluid and an environmental risk that requires costly cleanup.

The Constant Threat of Contamination

Contamination is the single greatest cause of hydraulic component failure. Solid particles (dirt, metal shavings) and water are the primary culprits.

These contaminants act like a liquid abrasive, accelerating wear on the tight tolerances inside pumps, valves, and cylinders. This leads to reduced performance, internal leakage, and eventual catastrophic failure. Effective filtration and clean assembly practices are not optional; they are essential for system survival.

The Inevitability of Fluid Degradation

Hydraulic fluid does not last forever. Over time, high temperatures and pressure cause the fluid's additives to break down, a process known as thermal degradation.

As the fluid degrades, its viscosity changes, and its ability to lubricate and protect components diminishes. This old fluid can form varnish and sludge that clogs filters and small orifices within valves, leading to erratic system behavior.

Inefficiency and Its Consequences

Hydraulic systems are renowned for force, not for energy efficiency. This inefficiency manifests primarily as heat.

Where Energy Is Lost

Significant energy is lost whenever hydraulic fluid flows from a high-pressure area to a low-pressure area without performing useful work. This happens constantly across relief valves, flow control valves, and even through internal component leakage.

This lost energy is converted directly into heat, which is absorbed by the hydraulic fluid.

The Vicious Cycle of Heat

Excessive heat is a system killer. As the fluid temperature rises, its viscosity drops, making it thinner and a less effective lubricant.

This reduction in viscosity increases internal leakage within components, which in turn generates even more heat. To combat this, many systems require large heat exchangers (coolers), adding cost, complexity, and another potential point of failure.

Understanding the Trade-offs

The problems of hydraulics are best understood as the trade-offs made to achieve their primary benefit: unmatched power density.

Complexity vs. Power Density

A hydraulic system is mechanically complex, involving a power unit, pumps, valves, actuators, filters, and a network of hoses and tubes. This complexity is the price paid for the ability to generate and control immense force from a relatively small package. An electric actuator of equivalent force would be significantly larger and heavier.

Maintenance Burden vs. Reliability

Hydraulic systems are not inherently unreliable, but they are unforgiving of neglect. Their reliability is directly proportional to the quality of the maintenance they receive. A proactive maintenance plan—involving regular fluid analysis, filter changes, and leak inspections—is critical to preventing costly downtime.

Safety and Environmental Risks

The use of petroleum-based hydraulic fluid introduces a significant fire hazard, especially in environments with ignition sources like welding or hot metal. While fire-resistant fluids are available, they are more expensive, can be less forgiving, and may require special seals and hoses, adding another layer of design trade-offs.

Is Hydraulics Right for Your Application?

Choosing to use hydraulic power requires a clear understanding of your operational priorities and a commitment to managing its inherent challenges.

- If your primary focus is maximum force in a compact space: Hydraulics is often the superior or only viable option, but you must budget for robust maintenance and heat management.

- If your primary focus is energy efficiency and a clean environment: A modern electromechanical system is likely a better choice, provided it can meet your force requirements.

- If your primary focus is simplicity and low cost for low-force tasks: A pneumatic system offers a simpler, cleaner, and often less expensive alternative.

By anticipating these challenges, you can design and maintain a hydraulic system that is not just powerful, but also dependable and cost-effective over its entire service life.

Summary Table:

| Problem | Primary Consequence | Key Management Strategy |

|---|---|---|

| Fluid Leaks | Safety hazards, environmental risk, operational cost | Proactive inspection and proper sealing |

| Contamination | Accelerated component wear and system failure | Rigorous filtration and clean assembly |

| Fluid Degradation | Loss of lubrication, sludge/varnish formation | Regular fluid analysis and scheduled changes |

| Energy Inefficiency | Excessive heat generation, reduced performance | Proper system design and use of heat exchangers |

Struggling with hydraulic system reliability? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our expertise can help you select and maintain the right hydraulic components to minimize downtime, improve safety, and extend equipment life. Contact our experts today to optimize your hydraulic systems for maximum dependability.

Visual Guide

Related Products

- Manual Lab Heat Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is KBr method in IR spectroscopy? Master Solid Sample Analysis for Clear IR Spectra

- What is the effect of particle size on XRF measurements? Achieve Accurate & Reliable Results

- What are the basics of a hydraulic press? Unlock the Power of Force Multiplication

- What kind of oil do you use in a hydraulic press? Choose the Right Hydraulic Oil for Peak Performance

- How does pressure control of a laboratory hydraulic press affect W-Ti alloys? Optimize Grain Structure & Density

- What are the technical advantages of using a manual hydraulic press with carbide dies? Achieve High-Density Green Bodies

- What role does a laboratory hydraulic press play in sulfide-based solid-state batteries? Achieve Optimal Densification

- Why is a powder hydraulic press used to create reaction pellets during the carbothermic reduction of magnesium?