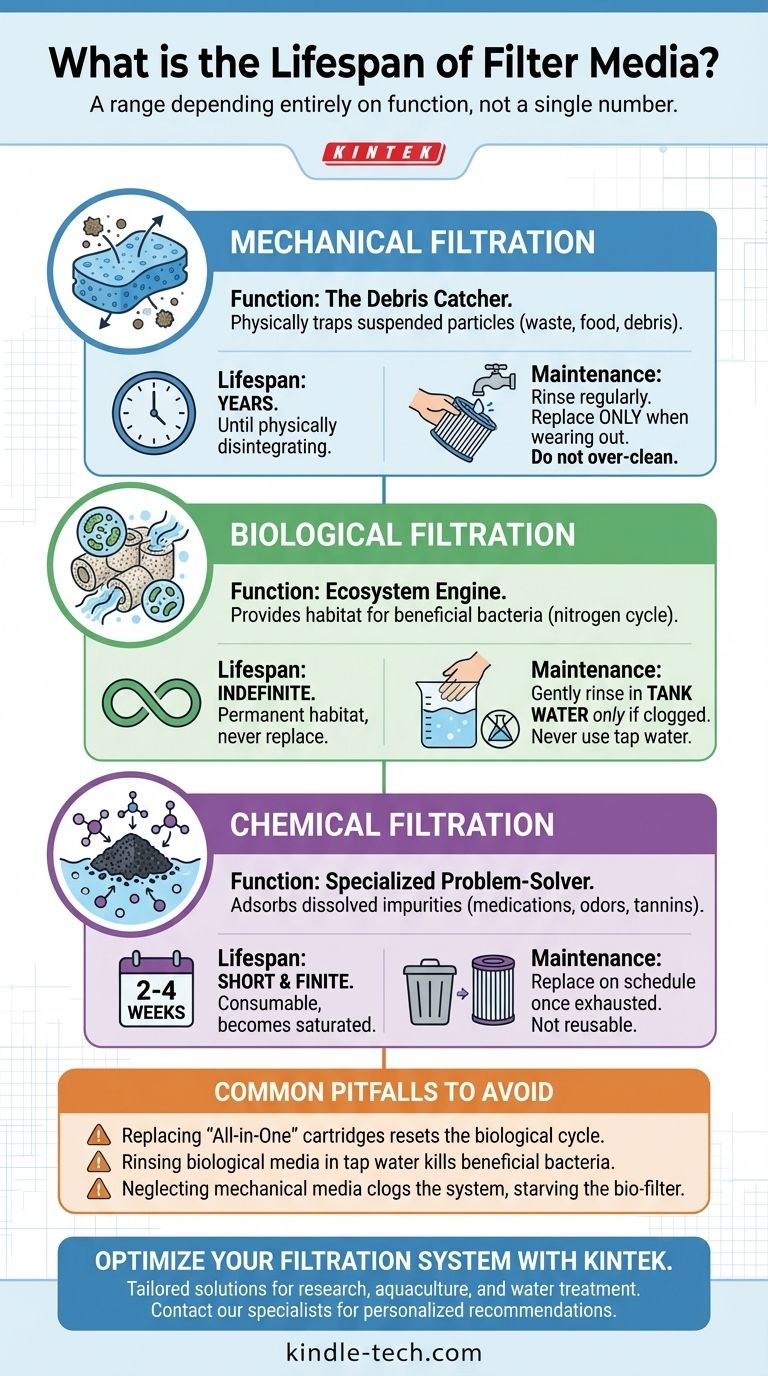

The lifespan of filter media is not a single number, but a range that depends entirely on its function. To answer the question properly, we must distinguish between the three primary types of filtration: mechanical, biological,and chemical. Chemical media like activated carbon lasts only a few weeks, mechanical media like sponges can last for years with proper cleaning, and biological media can function indefinitely.

The most common mistake is treating all filter media the same. The central principle of effective filtration is to understand that biological media is a permanent habitat to be preserved, mechanical media is a reusable screen to be cleaned, and chemical media is a disposable tool for specific, short-term tasks.

The Three Core Functions of Filter Media

Most comprehensive filtration systems, particularly in aquariums, are built on a three-stage process. Understanding the role of each stage is the key to knowing how to maintain it.

Mechanical Filtration: The Debris Catcher

The first stage of filtration is always mechanical. Its sole purpose is to physically trap suspended particles like fish waste, uneaten food, and plant debris from the water column.

This media is typically a sponge, filter floss, or pad. The material itself is durable and can last for years. Its functional lifespan, however, ends when it becomes clogged.

A clogged mechanical filter drastically reduces water flow, starving the other filter stages of oxygen and rendering the entire system ineffective. It must be cleaned regularly but only replaced when it is physically disintegrating.

Biological Filtration: The Engine of the Ecosystem

Biological filtration is the most critical process for a stable aquatic environment. It provides a high-surface-area home for beneficial bacteria to grow.

These bacteria perform the nitrogen cycle, converting toxic ammonia and nitrite into much less harmful nitrate. This media—often ceramic rings, sintered glass, or plastic "bio-balls"—is inert and does not degrade.

Therefore, the lifespan of biological media is indefinite. You should never replace it unless it is physically crushed or destroyed. The bacterial colony living on it is the actual "filter," and replacing the media means throwing away your entire biological engine.

Chemical Filtration: The Specialized Problem-Solver

Chemical filtration uses media that actively removes dissolved impurities from the water through adsorption or chemical reaction.

The most common example is activated carbon, which is excellent at removing medications, tannins (which color water yellow), and odors. Other examples include phosphate removers or ammonia absorbers.

This type of media has a very short and finite lifespan. Once its pores are saturated, it stops working. This typically happens within two to four weeks. After this point, it must be removed and replaced.

Understanding the Trade-offs and Common Pitfalls

Proper filter management is often counterintuitive, leading to mistakes that can destabilize the system you are trying to maintain.

The Myth of the "All-in-One" Cartridge

Many beginner-friendly filters use disposable cartridges that bundle filter floss (mechanical), activated carbon (chemical), and a plastic frame (a small amount of biological surface) into one unit.

The instructions tell you to replace this cartridge every month. This is a critical design flaw. When you throw the cartridge away, you are discarding the beneficial bacteria that have colonized the filter floss, which is acting as your primary biological filter.

This action effectively resets your nitrogen cycle, leading to dangerous ammonia and nitrite spikes. It creates a cycle of instability that is a frequent source of failure for new hobbyists.

Over-Cleaning vs. Under-Cleaning

There is a crucial balance in filter maintenance.

Over-cleaning, such as rinsing your biological media in untreated tap water, will kill the beneficial bacteria due to chlorine or chloramine. This has the same effect as replacing the media.

Under-cleaning, or neglecting the mechanical media, causes it to clog. This starves the biological filter of oxygenated water, causing the beneficial bacteria to die off and hindering its performance.

When to Clean vs. When to Replace

To simplify, media only needs to be replaced in two scenarios:

- Chemical media (like carbon) is always replaced on a schedule because it becomes exhausted.

- Mechanical media (like sponges) is only replaced when it is physically falling apart and can no longer be cleaned effectively.

Biological media is never replaced, only gently rinsed in tank water to remove excess sludge if flow becomes impeded.

Making the Right Choice for Your Goal

Your maintenance strategy should be dictated by your specific filtration goal.

- If your primary focus is a stable, long-term aquarium: Prioritize preserving your biological media above all else; treat it as permanent and clean it gently only when necessary.

- If your primary focus is removing medication or water discoloration: Use chemical media like activated carbon, but remember it is a temporary consumable that must be replaced every 3-4 weeks.

- If your primary focus is maintaining water clarity and flow: Regularly clean your mechanical media (sponges, floss) and only replace it when it begins to physically break down.

- If your primary focus is clean home air or drinking water: Strictly follow the manufacturer's replacement schedule, as these filters have a fixed, non-renewable lifespan measured in time or volume.

Proper filter management is not about adhering to a universal replacement schedule, but about understanding the distinct role and lifespan of each component in your system.

Summary Table:

| Filter Media Type | Primary Function | Typical Lifespan | Key Maintenance Action |

|---|---|---|---|

| Mechanical (Sponges, Floss) | Traps physical debris | Years (until physically worn) | Rinse regularly; replace only when disintegrating |

| Biological (Ceramic Rings, Bio-balls) | Hosts beneficial bacteria | Indefinite | Never replace; gently rinse in tank water if clogged |

| Chemical (Activated Carbon) | Removes dissolved impurities | 2-4 weeks | Replace on schedule once exhausted |

Optimize Your Filtration System with KINTEK

Understanding the distinct roles of your filter media is the first step toward a healthier lab or aquarium environment. At KINTEK, we specialize in providing high-quality lab equipment and consumables, including durable filtration media tailored to your specific needs—whether for research, aquaculture, or water treatment applications.

Let our experts help you select the right media to extend the life of your mechanical filters, sustain your biological ecosystem, or effectively manage chemical filtration tasks.

Contact us today to discuss your filtration challenges and discover how KINTEK can support your laboratory's efficiency and success.

Get in touch with our specialists now to receive personalized recommendations and enhance your system's performance.

Visual Guide

Related Products

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Custom PTFE Teflon Parts Manufacturer for Sampling Filters

- Longpass Highpass Filters for Optical Applications

- Custom PTFE Teflon Parts Manufacturer for PTFE Bottle Oil Fume Sampling Tube

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What is a sintered metal? A Guide to High-Strength, Complex Metal Parts

- What is the role of thin films in devices? The Invisible Engine of Modern Technology

- What are the 2 problems of biomass as a fuel? Overcome Energy Density & Cost Challenges

- Why is sputtering done in SEM? Prevent Charging and Get Clear Images of Non-Conductive Samples

- What is the future of pyrolysis oil? A Key to Circular Economy & Renewable Fuels

- What is heat treatment in manufacturing process? Transform Material Properties for Superior Performance

- What is the role of a laboratory mechanical stirrer in SA/PASP/RE preparation? Achieve Perfect Homogenization

- How is sintering performed? A Step-by-Step Guide to Fusing Powders into Solid Parts