When a hydraulic system leaks, the immediate result is a loss of fluid, but the consequences extend far beyond a simple puddle on the floor. A leak degrades system performance, causes escalating equipment damage, and creates significant safety and environmental hazards. It is a critical symptom of a system whose integrity is compromised.

A hydraulic leak is never just a "mess." It is a direct indicator of a system failure in progress, compromising operational power, safety, and financial efficiency. Ignoring a leak, no matter how small, invites cascading problems that are far more severe than the initial drip.

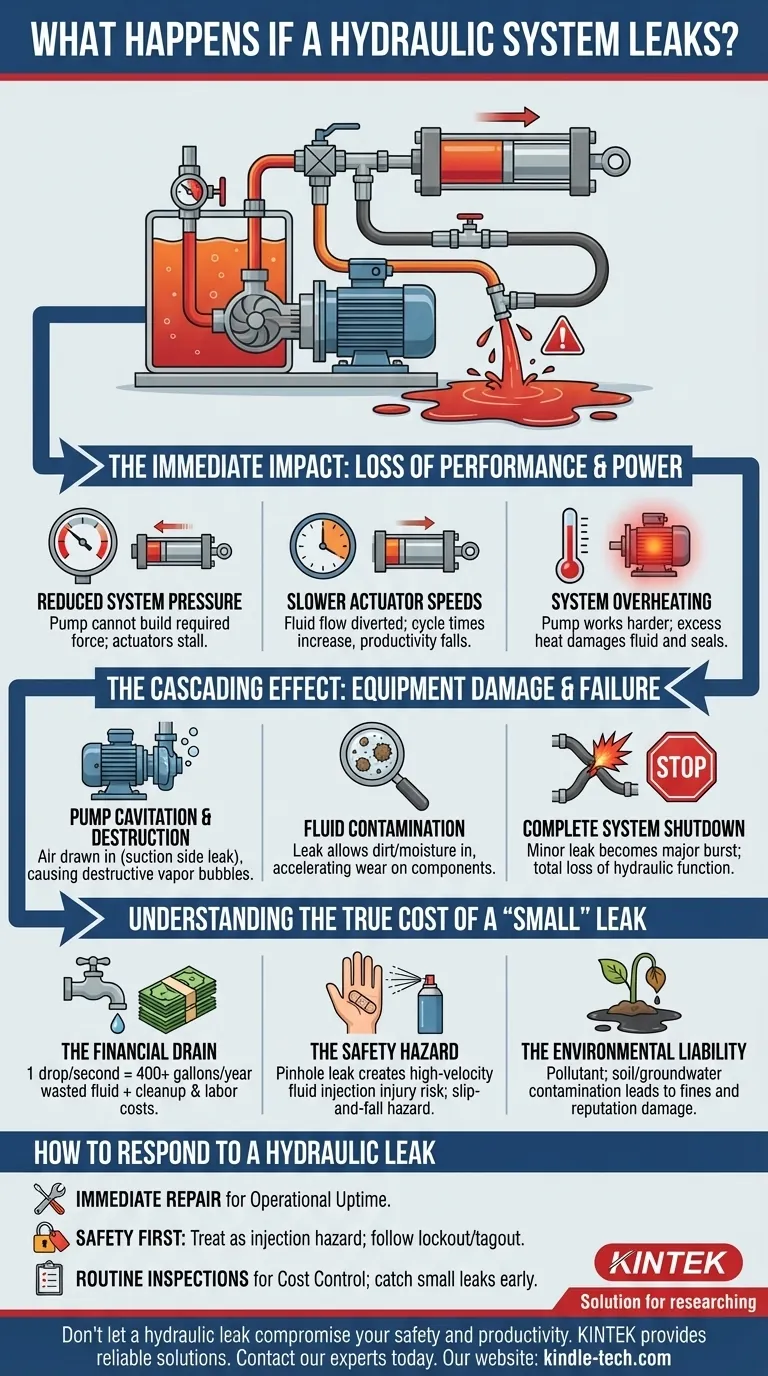

The Immediate Impact: Loss of Performance and Power

The most direct effect of a leak is on the system's ability to do work. Hydraulic power is a function of fluid flow and pressure, and a leak undermines both.

Reduced System Pressure

When fluid escapes, the pump cannot build or maintain the required pressure for the intended task. This translates directly into a loss of force, meaning actuators and cylinders may stall or be unable to lift their specified loads.

Slower Actuator Speeds

A leak diverts fluid flow that would otherwise be used to move an actuator. This causes cycle times to increase, slowing down the entire machine's operation and reducing productivity.

System Overheating

The pump must work harder to compensate for the lost fluid and pressure, generating excess heat. Furthermore, the reduced volume of oil in the system diminishes its ability to dissipate that heat, creating a vicious cycle of rising temperatures that can degrade the fluid and damage seals.

The Cascading Effect: Equipment Damage and Failure

A leak is a breach in a closed system, and the consequences quickly cascade from simple performance loss to permanent equipment damage.

Pump Cavitation and Destruction

If a leak is on the suction side of the pump or if the reservoir level drops too low, air gets drawn into the system. This leads to cavitation—the formation and violent collapse of vapor bubbles—which is extremely destructive to the pump's internal components.

Fluid Contamination

A leak is a two-way street. The opening that lets fluid out also allows contaminants like dirt, dust, and moisture to get in. This contamination is the leading cause of hydraulic component failure, as abrasive particles accelerate wear on sensitive valves, seals, and motors.

Complete System Shutdown

A minor leak can abruptly become a major failure, such as a burst hose. This results in a catastrophic loss of fluid, causing an immediate and total loss of hydraulic function and bringing all operations to a sudden halt.

Understanding the True Cost of a "Small" Leak

It is a common mistake to underestimate the impact of a seemingly minor drip. The true costs are often hidden and accumulate over time.

The Financial Drain

A single drop of fluid leaking every second adds up to over 400 gallons of wasted hydraulic oil in a year. Beyond the high cost of replacement fluid, you must also factor in the costs of cleanup materials, labor, and disposal.

The Safety Hazard

Pressurized hydraulic fluid represents a severe safety risk. A pinhole leak can create a high-velocity stream of oil that is nearly invisible yet powerful enough to cause a fluid injection injury, where oil penetrates the skin. These are medical emergencies that can lead to amputation or death. Furthermore, pooled oil creates a serious slip-and-fall hazard.

The Environmental Liability

Hydraulic oil is a pollutant. Uncontained leaks contaminate soil and groundwater, leading to significant environmental damage. This can result in steep regulatory fines, mandatory cleanup costs, and serious harm to a company's public reputation.

How to Respond to a Hydraulic Leak

Your response should be dictated by a clear understanding of these risks. A proactive approach is always the most effective.

- If your primary focus is operational uptime: Immediately identify, isolate, and repair any leak to prevent performance degradation and unplanned downtime.

- If your primary focus is safety: Treat every leak as a potential injection hazard, enforcing strict lockout/tagout procedures before any inspection or repair work begins.

- If your primary focus is cost control: Implement a routine inspection program to catch small leaks before they lead to expensive fluid loss, component failure, and cleanup liabilities.

Viewing a leak as critical system data, not just an inconvenience, is the foundation of reliable and safe hydraulic operation.

Summary Table:

| Impact Category | Key Consequences |

|---|---|

| Performance | Loss of pressure, slower cycle times, system overheating |

| Equipment Damage | Pump cavitation, fluid contamination, complete system shutdown |

| Cost & Safety | Wasted fluid, injection injuries, environmental fines |

Don't let a hydraulic leak compromise your safety and productivity. KINTEK specializes in lab equipment and consumables, providing reliable solutions for your laboratory's hydraulic system needs. Our expertise ensures your equipment operates at peak performance, minimizing downtime and risk. Contact our experts today for a consultation and protect your valuable assets.

Visual Guide

Related Products

- Manual Lab Heat Press

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- Why is a precision laboratory hydraulic press required for manufacturing molybdenum target green bodies?

- What products are made by roll forming? Discover the Versatile Applications Across Industries

- What is high pressure in hydraulics? Achieving Maximum Power Density for Your Equipment

- What is XRF sample preparation? Achieve Accurate and Reliable Elemental Analysis

- What is the function of a laboratory hydraulic press in PHA film production? Perfecting Bio-Packaging Standards

- How do you prepare samples for IR spectroscopy? A Step-by-Step Guide for Solids, Liquids, and Gases

- How does a roll press work? A Deep Dive into Continuous Compaction Technology

- What is a frame press used for? Unlock Versatile Bending, Assembly, and Forming