The primary machine used for sieving is a sieve shaker. This device agitates a stack of test sieves to separate particles by size. For highly specialized applications, such as analyzing very fine powders, an air jet sieving machine is used, which employs a different principle to achieve high-precision separation for particles between 5 and 4,000 microns.

Choosing a sieving machine is not about a single "best" device. The correct choice is dictated by two factors: the physical properties of your material and the objective of your analysis.

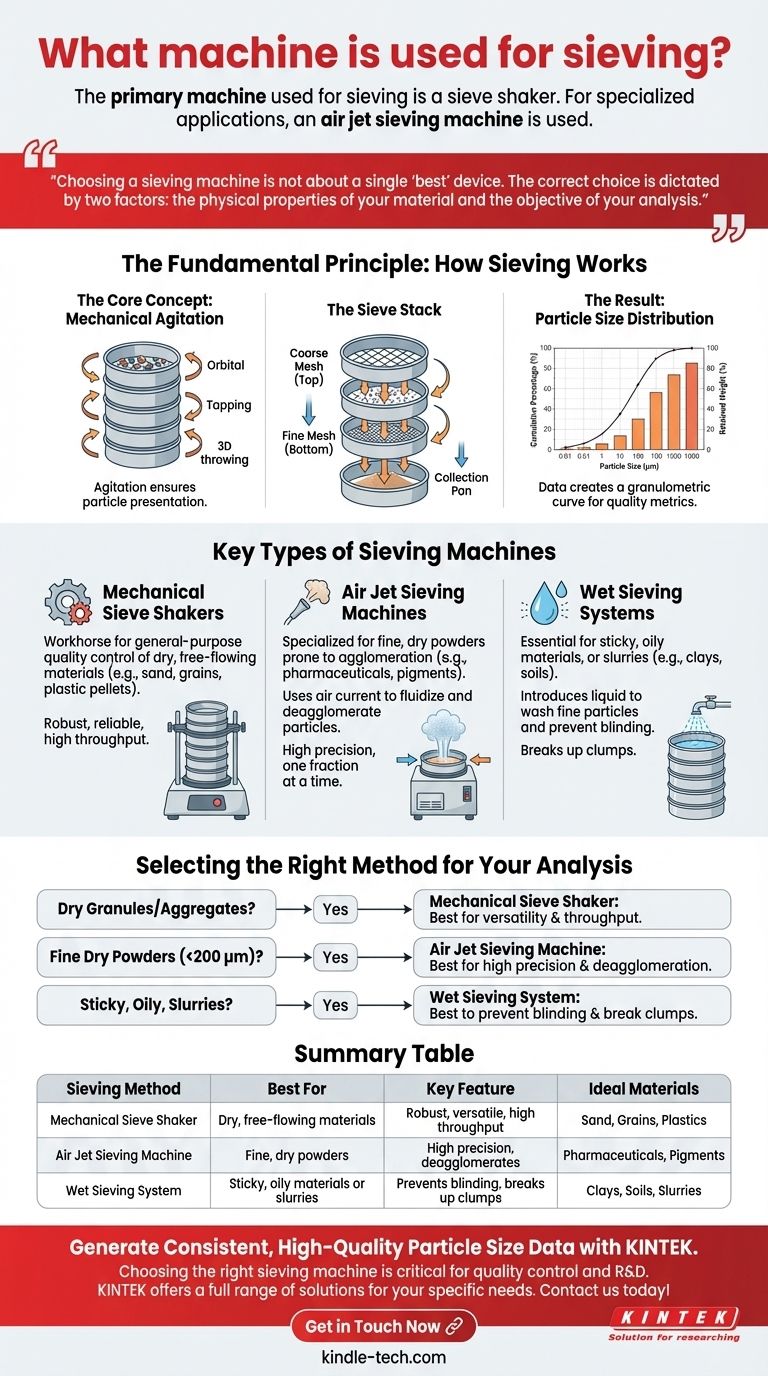

The Fundamental Principle: How Sieving Works

The goal of sieving is to determine the particle size distribution of a granular material. While machines vary, the underlying concept is universal.

The Core Concept: Mechanical Agitation

Most sieving machines work by imparting a specific motion to a stack of sieves. This can be a tapping motion, an orbital motion, or a 3D throwing motion. This agitation ensures all particles are presented to the sieve apertures multiple times and in multiple orientations.

The Sieve Stack

Sieves are stacked in descending order of mesh size, with the coarsest sieve on top and the finest at the bottom, above a solid collection pan. As the machine runs, particles fall through the apertures until they are retained by a sieve that is too fine for them to pass.

The Result: Particle Size Distribution

After the process is complete, the material retained on each sieve is weighed. This data creates a granulometric curve, or particle size distribution, which is a critical quality metric in countless industries.

Key Types of Sieving Machines

While a standard mechanical shaker is common, specific material properties may demand a specialized approach.

Mechanical Sieve Shakers

This is the most common type of sieving machine. It is the workhorse for general-purpose quality control of dry, free-flowing materials like sand, grains, or plastic pellets. They are robust, reliable, and can handle a wide range of particle sizes.

Air Jet Sieving Machines

This specialized instrument is designed for very fine, dry powders that tend to clump together (agglomerate) due to static forces. It uses a single test sieve and a rotating nozzle that blows a jet of air up through the mesh from below.

This air current fluidizes the powder on the sieve surface, deagglomerating the particles and clearing the mesh to ensure fine particles can pass through. This method provides excellent reproducibility for materials like pharmaceuticals, pigments, and metal powders.

Wet Sieving Systems

Modern sieving machines often support both dry and wet sieving. Wet sieving is essential for materials that cannot be separated in a dry state.

A liquid, typically water, is introduced into the top sieve. It washes the fine particles down through the sieve stack, breaking up clumps and preventing the mesh from getting clogged (blinding). This is ideal for materials like clays, soils, or samples suspended in a slurry.

Understanding the Trade-offs

Choosing the wrong method can lead to inaccurate and unreliable results. The decision between dry, wet, or air jet sieving is a critical first step.

When to Choose Dry Sieving

Dry sieving with a mechanical shaker is the default method. It is faster, requires less cleanup, and is perfectly suitable for any material that flows freely and does not exhibit significant static charge or stickiness.

When to Choose Wet Sieving

Wet sieving is non-negotiable for materials that are sticky, oily, or clump together. If your dry sieving results are inconsistent, or if the sieves become blinded, it is a clear indicator that you should switch to a wet method.

The Limitation of Air Jet Sieving

While extremely precise for fine powders, an air jet machine analyzes only one particle size fraction at a time (using one sieve). It is an analytical tool, not a method for bulk separation, and is only suitable for dry, non-sticky powders.

Selecting the Right Method for Your Analysis

Your material and your goal dictate the technology you need. Use these points as a guide.

- If your primary focus is routine quality control of dry granules or aggregates: A standard mechanical sieve shaker provides the best balance of versatility, throughput, and reliability.

- If your primary focus is high-precision analysis of fine, dry powders below 200 microns: An air jet sieving machine is specifically designed to overcome agglomeration and deliver the most accurate results.

- If your primary focus is analyzing materials that are sticky, form hard clumps, or are already in a liquid suspension: A wet sieving system is the only way to ensure particles separate correctly and you get an accurate result.

Understanding these distinct methods empowers you to generate consistent and meaningful data about your material's properties.

Summary Table:

| Sieving Method | Best For | Key Feature |

|---|---|---|

| Mechanical Sieve Shaker | Dry, free-flowing materials (e.g., sand, grains) | Robust, versatile, high throughput |

| Air Jet Sieving Machine | Fine, dry powders prone to clumping (e.g., pharmaceuticals) | High precision, deagglomerates particles |

| Wet Sieving System | Sticky, oily materials or slurries (e.g., clays, soils) | Prevents blinding, breaks up clumps |

Generate Consistent, High-Quality Particle Size Data with KINTEK

Choosing the right sieving machine is critical for accurate quality control and R&D. Whether you need the versatility of a mechanical shaker, the precision of an air jet machine, or the capability of a wet sieving system, KINTEK has the solution.

We specialize in providing reliable lab equipment, including a full range of sieving machines and consumables, to meet the specific needs of your laboratory. Our experts can help you select the perfect equipment to ensure your particle analysis is efficient, reproducible, and meaningful.

Contact us today to discuss your application and find the ideal sieving solution for your lab.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- How does a constant temperature shaker improve adsorption kinetics? Enhance Tetracycline Removal Accuracy

- What is the importance of powder sieving and mixing systems in additive manufacturing for HEA? Unlock Advanced Alloys

- What is the function of a benchtop mild shaker? Optimize Plasmonic Cellulose Paper Deposition with KINTEK Shakers

- What is a sieving shaker? Automate Your Particle Size Analysis for Accurate Results

- What are sieve shakers used for? Achieve Reliable Particle Size Analysis

- How does a precision sieving system contribute to waste eggshell powder in construction? Improve Strength & Stability

- What is the significance of using a fine sieving system for catalyst particles? Optimize Size for Maximum Reactivity

- How does a constant temperature rotary shaker contribute to evaluating iron nanoparticles? Optimize Dye Degradation