In short, ball mills can process an exceptionally wide array of materials. This includes substances ranging from soft and fibrous to extremely hard and brittle. The technique is commonly used to grind materials like chemicals, ceramics, glass, minerals, and other compounds into very fine powders, especially for small-scale laboratory work or for materials that resist other grinding methods.

The critical decision in ball milling isn't just what material you can process, but what material you use for the grinding jars and media. This choice directly impacts grinding efficiency, processing time, and, most importantly, the final purity of your sample.

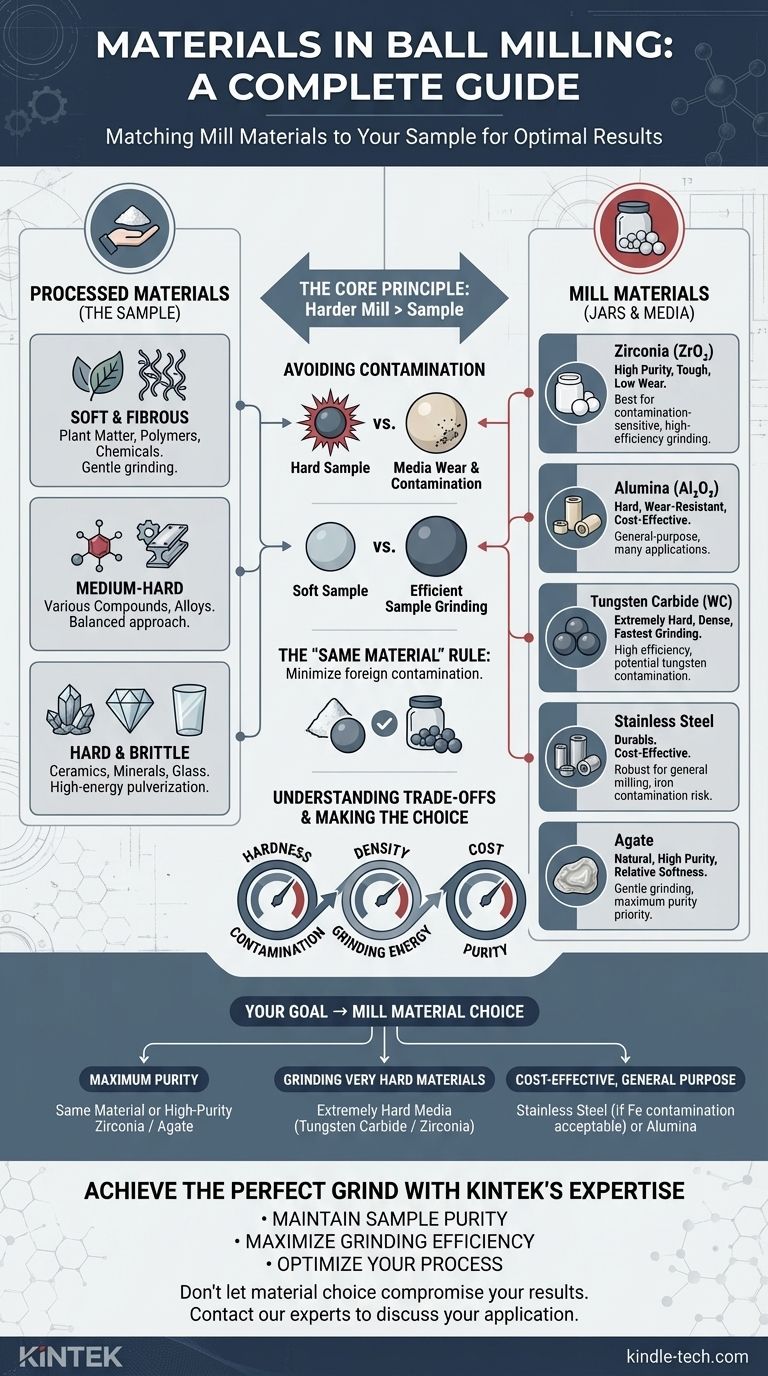

The Two Sides of Ball Milling Materials

When discussing materials in ball milling, it's essential to distinguish between the material being processed (the sample) and the materials used to construct the mill itself (the jar and grinding media).

Materials Processed by the Mill (The Sample)

Ball milling is a highly versatile size-reduction technique. It relies on high-energy impacts from grinding media to pulverize a sample.

Because of this mechanism, it works equally well on materials with very different properties, including:

- Hard & Brittle: Ceramics, minerals, glass, and metal oxides.

- Soft & Fibrous: Plant matter, polymers, and some chemicals.

- Medium-Hard: A vast range of chemical compounds and alloys.

The goal is typically to reduce these materials to a fine, homogenous powder with a controlled particle size.

Materials Used for the Mill (Jars & Media)

The "mill" consists of a grinding jar (the vessel) and the grinding media (typically balls) placed inside with the sample. The jar and media are usually made from the same material to prevent cross-contamination.

Common materials for jars and media include:

- Alumina (Al₂O₃): A hard, wear-resistant ceramic that is a good, cost-effective choice for many applications.

- Zirconia (ZrO₂): Harder and denser than alumina, providing higher grinding efficiency. It is very tough and highly resistant to wear, making it ideal for contamination-sensitive applications.

- Tungsten Carbide (WC): An extremely hard and dense material. It offers the fastest and most efficient grinding but is also the most expensive and can introduce tungsten contamination.

- Stainless Steel: A durable and cost-effective option, ideal for applications where metallic (iron/chrome) contamination is not a concern.

- Agate: A natural, pure form of quartz. It is relatively soft and best suited for gentle grinding of softer materials where maintaining the highest purity is the absolute priority.

The Core Principle: Avoiding Contamination and Wear

The selection of a jar and media material is governed by a simple principle: the mill must be harder than the sample. This minimizes wear on the mill components and, crucially, prevents contamination of the material being ground.

Matching Mill Hardness to the Sample

To effectively grind a material, the impact energy from the balls must be sufficient to fracture the sample particles. If the sample is harder than the grinding media, the balls will wear down instead of the sample.

This would not only be inefficient but would also introduce significant contamination from the worn-down media into your final product.

The "Same Material" Rule

In an ideal scenario, you mill a material using a jar and media made of that exact same material. For instance, you would mill high-purity alumina powder in an alumina jar with alumina balls.

This way, any minute particles that do wear off the jar or balls are chemically identical to the sample itself, representing "self-contamination" and preserving the material's purity.

Understanding the Trade-offs

Choosing a material for your grinding jar and media involves balancing performance, purity, and cost.

Hardness vs. Contamination

While a very hard material like tungsten carbide provides rapid grinding, it can introduce specific elemental contamination (tungsten, cobalt) if it wears. A softer material like agate poses no metallic contamination risk but cannot be used to grind hard samples.

Density vs. Grinding Energy

Denser media (like tungsten carbide) transfer more kinetic energy upon impact, leading to faster and more effective grinding. Lighter media (like agate or even some polymers) are used for "low-energy" milling where the goal is gentle homogenization rather than aggressive size reduction.

Cost vs. Purity

Stainless steel is a robust, low-cost choice, but it is not suitable for high-purity applications. High-purity zirconia offers an excellent balance of hardness, toughness, and low contamination but comes at a significantly higher cost.

Making the Right Choice for Your Goal

Your choice of jar and media material depends entirely on your sample and desired outcome.

- If your primary focus is maximum purity: Choose a jar and media material that is identical to your sample, or a highly inert material like high-purity Zirconia or Agate for softer samples.

- If your primary focus is grinding very hard materials: Select an extremely hard media like Tungsten Carbide or Zirconia, accepting the associated cost and potential for trace contamination.

- If your primary focus is cost-effective, general-purpose milling: Stainless steel is a robust and affordable option, provided that minor iron contamination is acceptable for your application.

By matching the mill's components to the properties of your sample, you can control the process and ensure the integrity of your results.

Summary Table:

| Material | Key Characteristics | Best Use Case |

|---|---|---|

| Zirconia (ZrO₂) | High hardness, toughness, low wear | High-purity, contamination-sensitive grinding |

| Alumina (Al₂O₃) | Hard, wear-resistant, cost-effective | General-purpose grinding of various materials |

| Tungsten Carbide (WC) | Extremely hard, dense, high efficiency | Grinding very hard materials where speed is critical |

| Stainless Steel | Durable, cost-effective | Applications where iron contamination is acceptable |

| Agate | Very pure, relatively soft | Gentle grinding of soft materials requiring maximum purity |

Achieve the perfect grind for your specific material with KINTEK's expertise.

Choosing the wrong grinding media can lead to sample contamination, inefficient processing, and wasted time. KINTEK specializes in laboratory ball mills and consumables, offering a full range of high-purity grinding jars and media—from zirconia and alumina to tungsten carbide—to match your exact application needs.

We help researchers and lab professionals like you:

- Maintain Sample Purity: Select media that prevents contamination.

- Maximize Grinding Efficiency: Get the right hardness and density for faster, more effective results.

- Optimize Your Process: Benefit from our technical guidance to choose the ideal setup.

Don't let material choice compromise your results. Contact our experts today to discuss your application and find the perfect ball milling solution for your lab.

Visual Guide

Related Products

- Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

- Laboratory Hybrid Tissue Grinding Mill

- Three-dimensional electromagnetic sieving instrument

- Low-Temperature Water-Cooled Touchscreen Vibratory Ultrafine Pulverizer

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

People Also Ask

- How does ultrasonic dispersion equipment assist in substrate pretreatment? Master Diamond Thin Film Nucleation

- What is the role of laboratory stirring equipment in nZVI preparation? Achieve Stable and Uniform Nano Slurries

- What are the different types of pulverization? Match the Method to Your Material and Goal

- What advantages does a high energy nano mill offer over a traditional ball mill? Optimize Your LiFePO4 Cathode Quality

- What safety checks should you do before using a grinder? Master the 3-Pillar Inspection for Accident-Free Operation

- What are the design advantages of the grinding chambers in jet mills? Achieve Ultra-Pure Size Reduction Without Wear

- What is the feed and product size of a ball mill? Achieve Fine to Ultra-Fine Grinding

- What is the primary purpose of using zirconia (ZrO2) grinding balls? Optimize Purity in ZrB2–SiC–TaC Milling