The most effective methods for reducing energy consumption in Ultra-Low Temperature (ULT) freezers involve a combination of operational changes, diligent maintenance, and strategic hardware choices. Adjusting the temperature setpoint from -80°C to -70°C can cut energy use by up to 30%, while modern technologies like variable speed compressors and superior insulation offer even greater long-term savings.

The core challenge with ULT freezers is their need for continuous, 24/7 operation to protect valuable samples. True efficiency is achieved not by a single fix, but by layering simple behavioral changes with smart maintenance and technology investments.

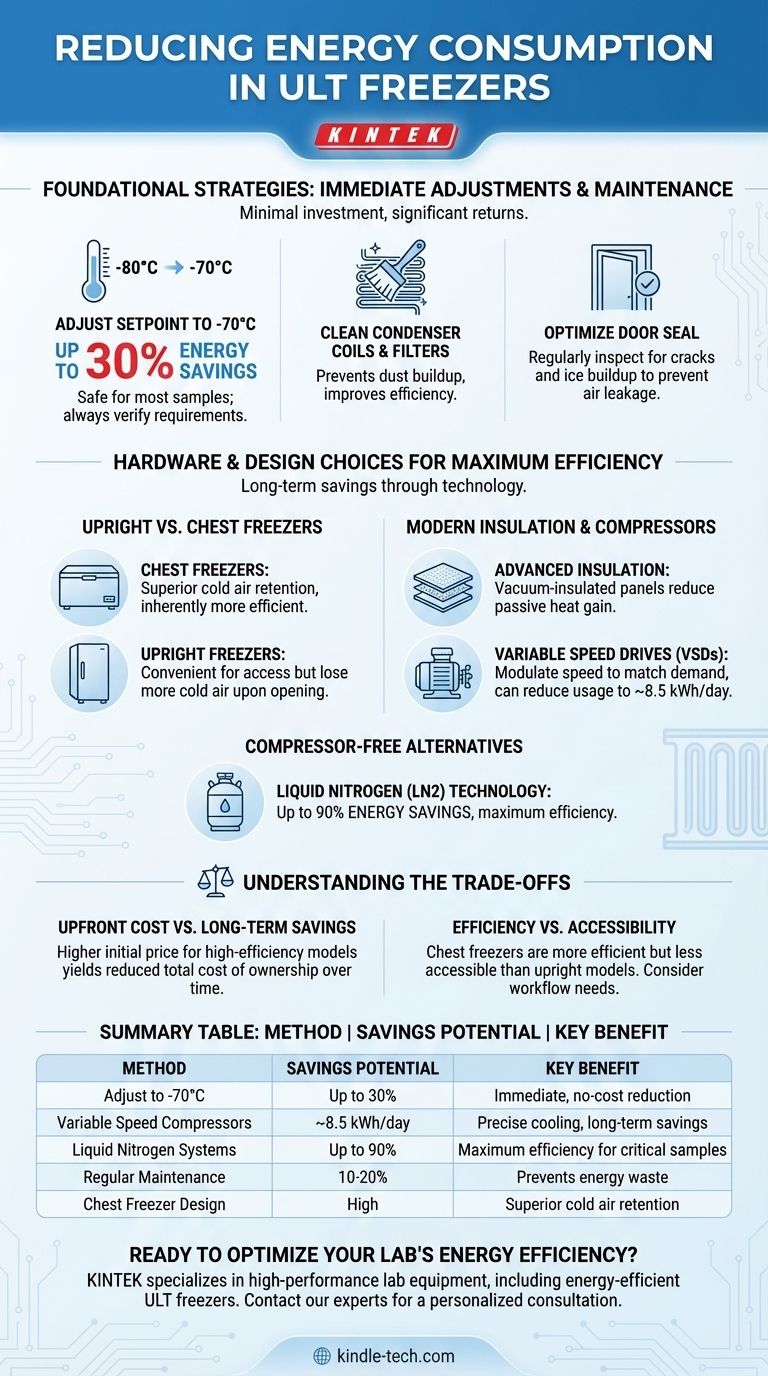

Foundational Strategies: Immediate Adjustments & Maintenance

These initial steps require minimal investment but yield significant returns by optimizing the performance of your existing equipment.

The -70°C vs. -80°C Decision

The single most impactful change you can make is adjusting the freezer's setpoint. Raising the temperature from the traditional -80°C to -70°C has been shown to reduce energy consumption by as much as 30%.

For the vast majority of biological samples, this temperature is perfectly safe for long-term storage. Always verify specific storage requirements, but this adjustment is a primary driver of efficiency.

The Critical Role of Routine Maintenance

A poorly maintained freezer works harder, consuming more energy to hold its temperature.

Regularly cleaning condenser coils and filters prevents dust buildup, which insulates the coils and forces the compressor to run longer. Similarly, minimizing ice buildup (defrosting) improves thermal efficiency and ensures a proper door seal.

Optimizing the Door Seal

The seal is the primary barrier between the ultra-low internal temperature and the ambient room temperature.

Inspect door gaskets regularly for any cracks, brittleness, or gaps that allow cold air to escape and warm air to enter. A faulty gasket is a constant source of energy waste.

Hardware and Design Choices for Maximum Efficiency

When purchasing a new ULT freezer or upgrading an existing one, the physical design and underlying technology are paramount for long-term energy savings.

Upright vs. Chest Freezers

The physical orientation of the freezer has a direct impact on efficiency. Chest freezers are inherently more energy-efficient than upright models.

Because cold air is dense, it pools at the bottom. When you open a top-loading chest freezer, very little cold air is lost. In contrast, cold air literally "falls out" of an upright freezer when the door is opened, forcing the system to work hard to restore the temperature.

The Impact of Modern Insulation

Effective insulation reduces passive heat gain, lessening the load on the cooling system. Modern freezers often use vacuum-insulated panels and other advanced materials that provide superior thermal resistance compared to older models.

Advanced Compressor Technology

Modern freezers often employ variable speed drives (VSDs) for their compressors and fans. Instead of a simple on/off cycle, these drives modulate their speed to precisely match the cooling demand.

This technology alone can reduce daily energy consumption to approximately 8.5 kWh/day, representing a significant improvement over older, single-speed compressors.

Compressor-Free Alternatives

For the absolute highest level of efficiency, some models use liquid nitrogen (LN2) technology instead of traditional compressors. These systems can reduce energy consumption by up to 90%, drastically lowering operational costs and environmental impact.

Understanding the Trade-offs

Pursuing energy efficiency requires balancing cost, convenience, and the absolute security of your samples.

Upfront Cost vs. Long-Term Savings

High-efficiency freezers with VSDs, advanced insulation, or LN2 systems command a higher initial purchase price.

However, their lower daily energy consumption results in a reduced total cost of ownership over the freezer's lifespan. This initial investment pays dividends through years of lower electricity bills.

Efficiency vs. Accessibility

While chest freezers are the clear winner in energy efficiency, they can be less convenient for sample management. Locating and retrieving specific samples can be more difficult compared to the organized shelving of an upright model.

This trade-off between energy performance and workflow convenience is a critical consideration for any lab.

Making the Right Choice for Your Lab

Your ideal strategy depends on your budget, existing infrastructure, and operational priorities.

- If your primary focus is immediate, low-cost savings: Adjust all capable freezers to -70°C and implement a strict bi-annual schedule for cleaning coils and checking door gaskets.

- If your primary focus is long-term cost reduction: When purchasing new equipment, invest in a model with a variable speed drive compressor or, for critical applications, consider a liquid nitrogen-based system.

- If your primary focus is maximizing sample access: Choose a high-efficiency upright model that includes multiple inner doors to minimize temperature loss during brief openings.

By strategically combining operational discipline with informed technology choices, you can achieve substantial energy savings without compromising the integrity of your critical work.

Summary Table:

| Method | Energy Saving Potential | Key Benefit |

|---|---|---|

| Adjust setpoint to -70°C | Up to 30% | Immediate, no-cost reduction |

| Variable speed compressors | ~8.5 kWh/day | Precise cooling, long-term savings |

| Liquid nitrogen systems | Up to 90% | Maximum efficiency for critical samples |

| Regular maintenance | 10-20% | Prevents energy waste from poor upkeep |

| Chest freezer design | High | Superior cold air retention |

Ready to optimize your lab's energy efficiency? KINTEK specializes in high-performance lab equipment and consumables, including energy-efficient ULT freezers with advanced features like variable speed compressors. Our experts can help you select the right solution to reduce operational costs while ensuring sample integrity. Contact us today for a personalized consultation!

Visual Guide

Related Products

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

People Also Ask

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- What is the temperature control capability of ultra-low freezers? Precise Stability Down to -86°C

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency