The most critical precautions for an evaporation lab revolve around managing the system's three core hazards: high vacuum, high temperature, and high voltage. You must always wear appropriate personal protective equipment (PPE), especially safety glasses, and strictly follow established operating procedures for the specific system you are using. Never work alone, and always ensure you are fully trained before operating the equipment.

The goal of evaporation lab safety is not just to avoid injury, but to create a controlled environment where predictable results are possible. This requires a deep respect for the extreme conditions inside the chamber and a methodical approach to every step, from loading the sample to venting the system.

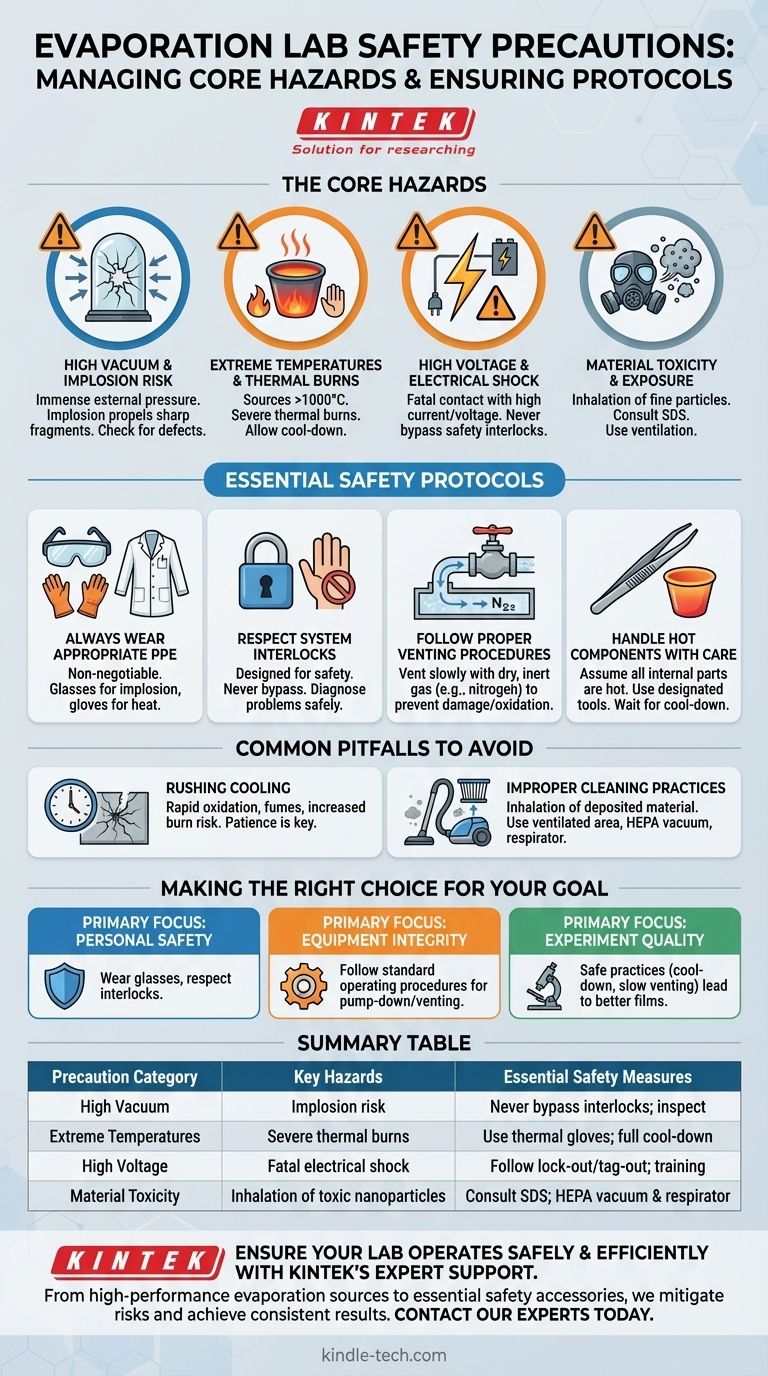

The Core Hazards of Evaporation Systems

To implement effective safety measures, you must first understand the inherent risks of the equipment. Evaporation systems create a highly artificial environment by combining conditions that are individually hazardous.

High Vacuum and Implosion Risk

A high-vacuum chamber contains an enormous amount of stored energy. The external atmospheric pressure exerts immense force on every surface of the chamber.

If there is a crack, defect, or weak point—especially in a glass bell jar or viewport—the chamber can fail catastrophically. This results in an implosion, where air rushes in violently, potentially propelling sharp fragments outward.

Extreme Temperatures and Thermal Hazards

The evaporation process requires heating a source material to temperatures high enough to cause vaporization, often well over 1000°C.

This creates a significant risk of severe thermal burns. The source, the crucible, and even the chamber walls can remain dangerously hot long after the power has been turned off. Some systems also use cryogenic materials like liquid nitrogen for pumping, which presents a risk of cold burns and asphyxiation in poorly ventilated areas.

High Voltage and Electrical Shock

The power supplies used to heat the evaporation sources operate at high currents and potentially high voltages. Contact with these electrical components can be fatal.

Modern systems are equipped with safety interlocks that are designed to cut power if the chamber is opened. However, older systems may lack these features, and any attempt to bypass interlocks on any machine is extremely dangerous.

Material Toxicity and Exposure

The materials you are evaporating can be hazardous. When vaporized and deposited as a thin film, they exist in a nanoparticle form.

These fine particles can be easily inhaled if the chamber is opened while they are still airborne, or if cleaning is performed improperly. Some materials are toxic, and you must consult the Safety Data Sheet (SDS) for any material before use.

Essential Safety Protocols

Your actions and procedures are the primary barrier between you and the hazards.

Always Wear Appropriate PPE

Personal Protective Equipment is non-negotiable. The absolute minimum includes:

- Safety Glasses: These must be worn at all times in the lab to protect against the risk of implosion.

- Thermal Gloves: Use these when handling any parts that have been inside the chamber, even if you think they have cooled.

- Lab Coat: Provides a basic barrier against material contamination.

Respect System Interlocks

Safety interlocks are designed to prevent you from accessing high-voltage components or breaking the vacuum seal inappropriately. Never bypass an interlock. If an interlock is preventing the system from operating, it is signaling a problem that must be diagnosed and fixed safely.

Follow Proper Venting Procedures

Bringing the chamber back to atmospheric pressure must be done slowly and carefully. Venting too quickly can create turbulence that damages your sample or stirs up particulate matter. Always use a dry, inert gas like nitrogen for venting to prevent rapid oxidation of the hot source materials and your freshly deposited film.

Handle Hot Components with Care

Assume all internal components are hot. Use long tweezers or designated tools to load and unload source materials and substrates. Set a clear "cool-down" time before you attempt to open the chamber after a deposition run.

Common Pitfalls to Avoid

Even experienced users can make mistakes, often by trying to save time. These shortcuts introduce significant risk.

The Temptation to Rush Cooling

Opening the chamber while the source material is still extremely hot can cause it to rapidly oxidize, potentially ruining the source and releasing fumes. More importantly, it dramatically increases your risk of a severe burn. Patience is a critical safety tool.

Improper Cleaning Practices

When cleaning the chamber walls and shields, you are handling the deposited material. This dust can be easily inhaled. Cleaning should be done in a ventilated area, often with a vacuum cleaner equipped with a HEPA filter, and you may need a respirator depending on the material's toxicity.

Making the Right Choice for Your Goal

Your approach to safety should be holistic, protecting yourself, the equipment, and the quality of your scientific results.

- If your primary focus is personal safety: Always wear your safety glasses from the moment you enter the lab until you leave, and never bypass a safety interlock.

- If your primary focus is equipment integrity: Follow the standard operating procedures for pump-down and venting without deviation, as these are designed to protect sensitive components like pumps and gauges.

- If your primary focus is experiment quality: Acknowledge that safe practices, like allowing proper cool-down and slow venting, directly lead to better, more reliable films by preventing oxidation and contamination.

Ultimately, robust safety protocols are the foundation of successful and repeatable scientific work.

Summary Table:

| Precaution Category | Key Hazards | Essential Safety Measures |

|---|---|---|

| High Vacuum | Implosion risk from chamber failure | Never bypass safety interlocks; inspect for defects |

| Extreme Temperatures | Severe thermal burns from hot sources | Use thermal gloves; allow full cool-down before handling |

| High Voltage | Fatal electrical shock from power supplies | Follow lock-out/tag-out procedures; ensure proper training |

| Material Toxicity | Inhalation of toxic nanoparticles | Consult SDS; use HEPA vacuum and respirator for cleaning |

Ensure your lab operates safely and efficiently with KINTEK's expert support.

Evaporation processes demand precision and rigorous safety protocols. KINTEK specializes in providing reliable lab equipment and consumables tailored to your laboratory's unique needs. From high-performance evaporation sources to essential safety accessories, we help you mitigate risks and achieve consistent, high-quality results.

Don't compromise on safety or performance—contact our experts today to discuss how we can support your evaporation lab requirements.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What happens to heat generated in a vacuum? Mastering Thermal Control for Superior Materials

- What are the failures of heat treatment? Predict and Prevent Cracking, Warping, and Soft Spots

- Is heat Cannot travel in a vacuum True or false? Discover How Heat Crosses the Void of Space

- At what temperature does molybdenum evaporate? Understanding Its High-Temperature Limits

- Why is high-temperature vacuum heat treatment critical for Cr-Ni steel? Optimize Strength & Surface Integrity