At the heart of modern ULT freezers, you will find natural hydrocarbon (HC) refrigerants, most commonly a mixture of propane and ethane. These gases are chosen over older synthetic refrigerants because they are significantly more energy-efficient and have a much lower environmental impact. They are easily liquefied and have well-understood thermal properties, making them ideal for the demanding task of achieving ultra-low temperatures.

The central takeaway is that the refrigerant choice in ULT freezers reflects a critical shift in priorities. Moving from older, environmentally harmful HFCs to natural hydrocarbons like propane and ethane is a direct response to the need for greater energy efficiency and sustainability in the lab.

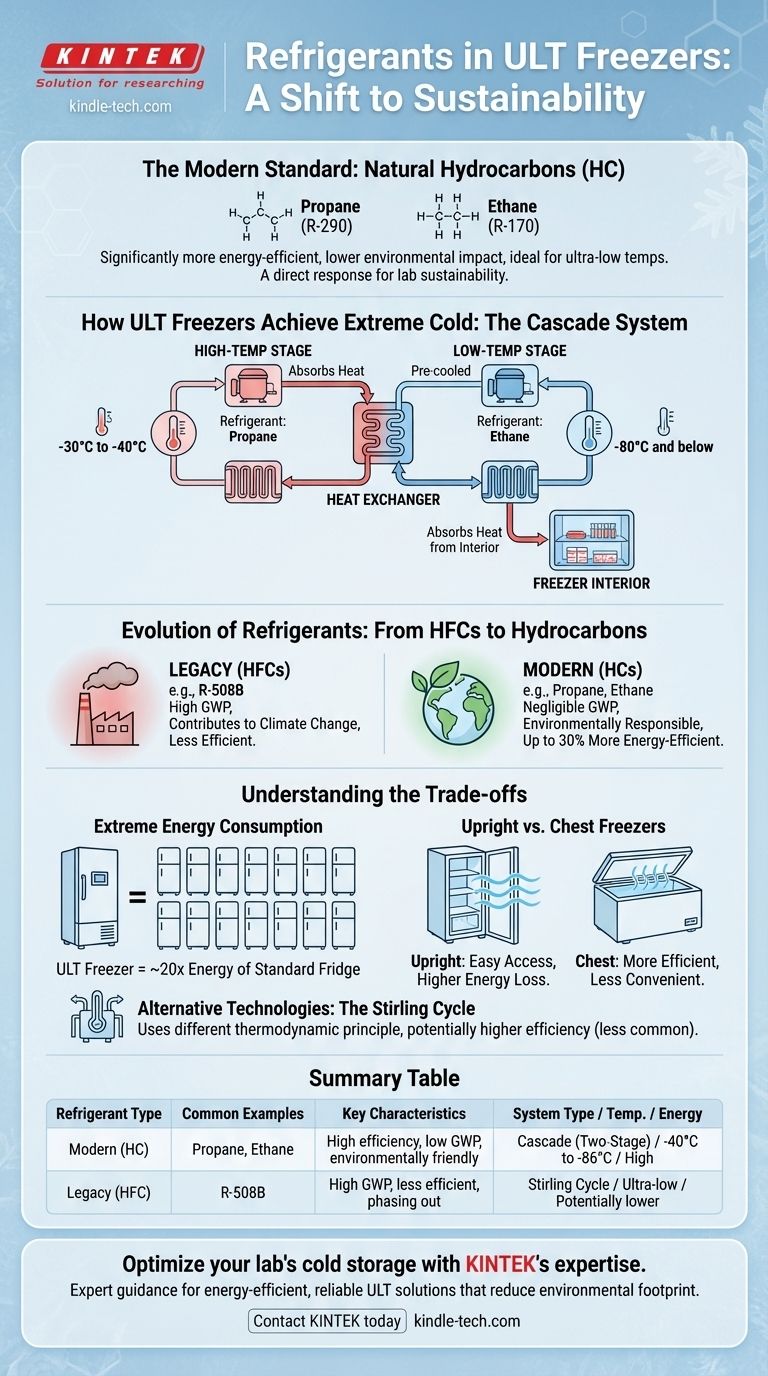

How ULT Freezers Achieve Extreme Cold: The Cascade System

Most ultra-low temperature freezers do not use a single refrigeration circuit. Instead, they rely on a cascade refrigeration system, which is essentially two cooling systems working together to reach temperatures of -40°C and below.

The High-Temperature Stage

The first stage, or high-temperature loop, functions much like a standard household refrigerator. It typically uses a refrigerant like propane to cool the system down to an intermediate temperature, often around -30°C to -40°C.

This initial cooling is crucial, but it cannot reach the target ultra-low temperature on its own. Its primary job is to absorb heat from the second stage of the system.

The Low-Temperature Stage

The second stage, or low-temperature loop, is what achieves the final, extreme cold. This loop uses a different refrigerant, such as ethane, which has a much lower boiling point.

This second circuit is "pre-cooled" by the first stage. By starting from an already cold -40°C instead of room temperature, the second stage can efficiently pull the freezer's interior down to its final setpoint, such as -80°C.

The Heat Exchange

The two stages are linked by a heat exchanger. Here, the refrigerant in the cold, low-temperature loop absorbs heat from the freezer's interior, causing it to evaporate. This gaseous refrigerant then flows through the heat exchanger, where its heat is transferred to the colder refrigerant of the high-temperature loop, before being compressed again.

The Evolution of Refrigerants: From HFCs to Hydrocarbons

The choice of propane and ethane is not arbitrary; it represents a significant technological and environmental evolution.

The Problem with Older Refrigerants (HFCs)

Previously, ULT freezers relied on chlorofluorocarbon (CFC) and hydrofluorocarbon (HFC) refrigerants, such as R-508B. While effective, these synthetic gases have an extremely high Global Warming Potential (GWP), contributing significantly to climate change if they leak.

Furthermore, systems using these older refrigerants are often less efficient, consuming more electricity to achieve the same level of cooling.

The Rise of Natural Hydrocarbons (HCs)

Modern ULT freezers have transitioned to natural hydrocarbon (HC) refrigerants like propane and ethane. These gases have a negligible GWP, making them a far more environmentally responsible choice.

Crucially, HC refrigerants are also more thermodynamically efficient. A ULT freezer using hydrocarbons can be up to 30% more energy-efficient than an equivalent model using older HFCs, leading to lower long-term operating costs.

Understanding the Trade-offs

While effective, the technology behind ULT freezers involves significant operational considerations.

Extreme Energy Consumption

A cascade refrigeration system is powerful but incredibly energy-intensive. A single ULT freezer can consume as much as 20 times the energy of a standard household refrigerator, making it a major source of electricity usage in any facility.

Upright vs. Chest Freezers

The physical design of the freezer impacts performance. Chest freezers are generally more energy-efficient because cold air is dense and does not "spill out" when the lid is opened. However, they take up more floor space and can be less convenient for organizing and accessing samples.

Upright freezers offer easier access and better organization but lose more cold air during door openings, leading to higher energy consumption to maintain temperature.

Alternative Technologies: The Stirling Cycle

A small number of ULT freezers use an alternative technology known as a Stirling cycle cooler. This system uses a different thermodynamic principle and avoids the complex two-stage cascade system, often resulting in higher efficiency and reliability, though it remains a less common option.

Making the Right Choice for Your Lab

Selecting a ULT freezer requires balancing performance, efficiency, and usability based on your specific needs.

- If your primary focus is minimizing operating costs and environmental impact: Choose a modern freezer that explicitly uses natural hydrocarbon (HC) refrigerants.

- If your primary focus is frequent sample access and organization: An upright freezer is the most practical choice, but be prepared for its higher energy consumption.

- If your primary focus is long-term, stable storage with minimal access: A chest freezer provides the best temperature stability and energy efficiency.

Understanding the technology inside your freezer empowers you to make a decision that aligns with both your scientific goals and your operational resources.

Summary Table:

| Refrigerant Type | Common Examples | Key Characteristics |

|---|---|---|

| Modern (HC) | Propane, Ethane | High efficiency, low GWP, environmentally friendly |

| Legacy (HFC) | R-508B | High GWP, less efficient, being phased out |

| System Type | Typical Temp. Range | Energy Use |

| Cascade (Two-Stage) | -40°C to -86°C | High (most common) |

| Stirling Cycle | Ultra-low temperatures | Potentially higher efficiency (less common) |

Optimize your lab's cold storage with KINTEK's expertise.

Choosing the right ULT freezer is critical for your research integrity and operational costs. Our team at KINTEK specializes in laboratory equipment and can help you select the ideal freezer—whether you prioritize energy-efficient hydrocarbon models, convenient upright designs, or stable chest freezers for long-term storage.

We provide expert guidance to ensure your investment delivers reliable performance, reduces your environmental footprint, and lowers long-term energy expenses.

Contact KINTEK today for a personalized consultation and let us help you find the perfect ULT solution for your laboratory's specific needs.

Visual Guide

Related Products

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 28L Compact Upright Ultra Low Temperature Freezer for Laboratory

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 108L Vertical Ultra Low Temperature ULT Freezer

People Also Ask

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples

- What is the temperature control capability of ultra-low freezers? Precise Stability Down to -86°C

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C